Understanding the Role of Seal Oil in Crankshaft Performance and Maintenance

The Role of Seal Oil in Crankshaft Performance

In the realm of automotive and mechanical engineering, the crankshaft serves as a fundamental component responsible for converting linear motion into rotational motion. It is pivotal in various machines, particularly internal combustion engines. While the design and material of a crankshaft are critical, one often overlooked aspect is the lubrication system, particularly seal oils. This article aims to elucidate the role of seal oil in crankshaft performance and maintenance, emphasizing its benefits, common challenges, and the advancements in oil technology.

Understanding Crankshaft Mechanics

The crankshaft operates under extreme conditions, experiencing high temperatures and pressures. As it rotates, it must maintain efficiency to prevent loss of power and ensure reliability. Proper lubrication is essential to minimize friction and wear between the crankshaft and the bearings it interacts with. This is where seal oil plays a crucial role.

Seal oil serves as a protective barrier, ensuring that particulate contaminants do not enter the internal components of the engine. It also facilitates a seamless interface between the crankshaft and the engine block, reducing the risk of leaks that could lead to catastrophic failures.

Importance of Seal Oil

1. Friction Reduction The primary benefit of seal oil is its ability to reduce friction. By creating a thin film between moving components, seal oil minimizes direct contact between the crankshaft and bearings. This not only improves efficiency but also extends the lifespan of these components.

2. Heat Dissipation As the crankshaft operates, it generates heat due to friction, which can lead to thermal expansion and potential damage. Seal oil acts as a coolant, helping to absorb and dissipate this heat, thereby maintaining optimal operating temperatures.

3. Contaminant Protection Seal oils are designed to repel dirt, dust, and other contaminants that could compromise the integrity of the crankshaft and its associated parts. Effective sealing prevents these contaminants from interfering with the engine’s operation, thereby enhancing reliability and performance.

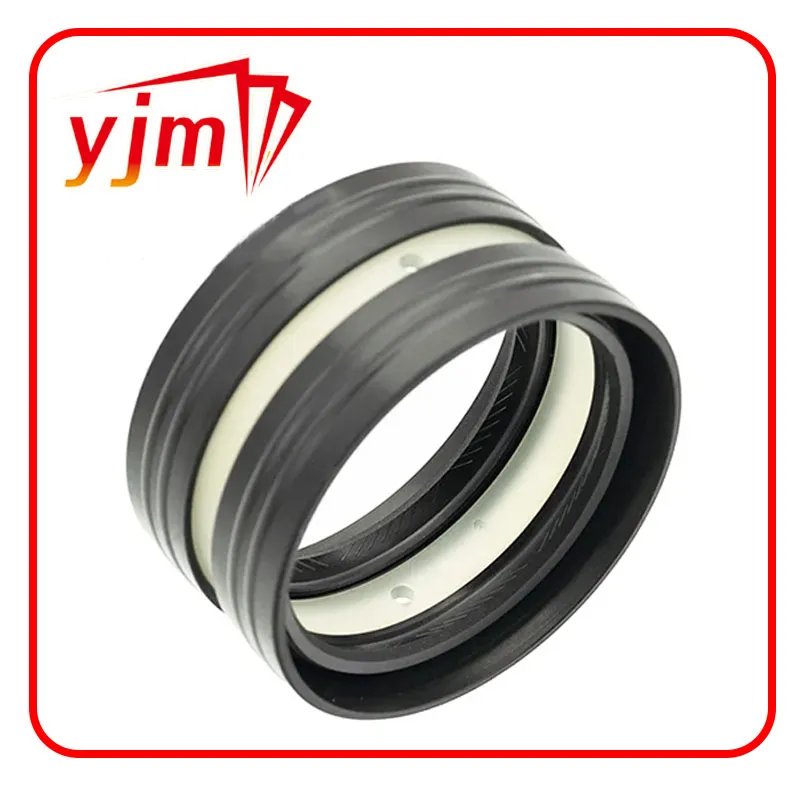

seal oil crankshaft

4. Corrosion Resistance Over time, exposure to moisture and other elements can lead to corrosion. A quality seal oil not only lubricates but also forms a protective barrier against oxidizing agents, ensuring the internal surfaces of the crankshaft remain in good condition.

Challenges and Considerations

While seal oil is crucial for crankshaft performance, it is not without challenges. One of the most significant issues is the contamination of the oil itself. Over time, seal oils can become degraded due to the heat and stress of continuous operation, leading to the formation of sludge and deposits. These can obstruct lubrication pathways, resulting in increased wear and tear on the crankshaft.

Additionally, the compatibility of seal oil with various materials is crucial. Some oils may not react well with certain rubber or plastic components used in seals, which can lead to leakage and subsequent failures. It is essential for engineers and mechanics to select the appropriate type of seal oil that not only meets the lubricating requirements but also complements the materials involved.

Advancements in Oil Technology

The advancement of oil formulation technology has brought about significant improvements in seal oil performance. Modern seal oils often incorporate synthetic bases, which offer enhanced stability, better high-temperature resistance, and improved protective properties. Many high-performance oils now contain additives designed to minimize wear, enhance thermal stability, and resist oxidation – further extending the life of the crankshaft and associated components.

Moreover, the growing trend of environmentally friendly oil formulations is reshaping the market. These biodegradable and less toxic alternatives not only meet performance criteria but also align with contemporary environmental sustainability goals.

Conclusion

In conclusion, seal oil plays a vital role in the performance and longevity of crankshafts within internal combustion engines and other machinery. Its benefits far exceed simple lubrication; it protects against wear, dissipates heat, and prevents contamination. As technology evolves, selecting the right seal oil will remain crucial for maintaining engine efficiency and reliability. By understanding the significance of seal oils, engineers and vehicle owners can make informed decisions that lead to optimal performance and extended equipment lifespans.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories