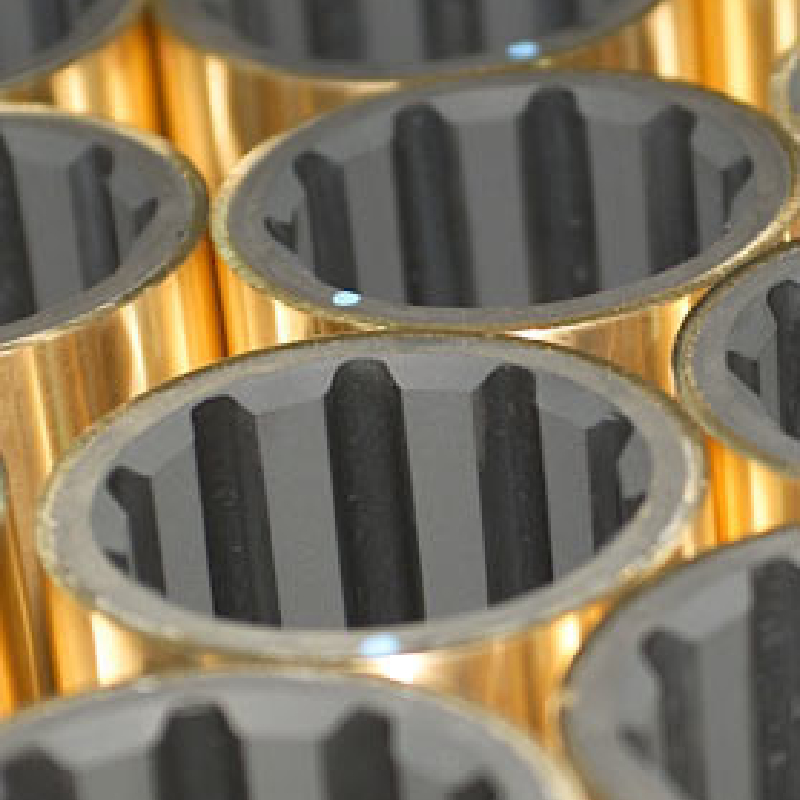

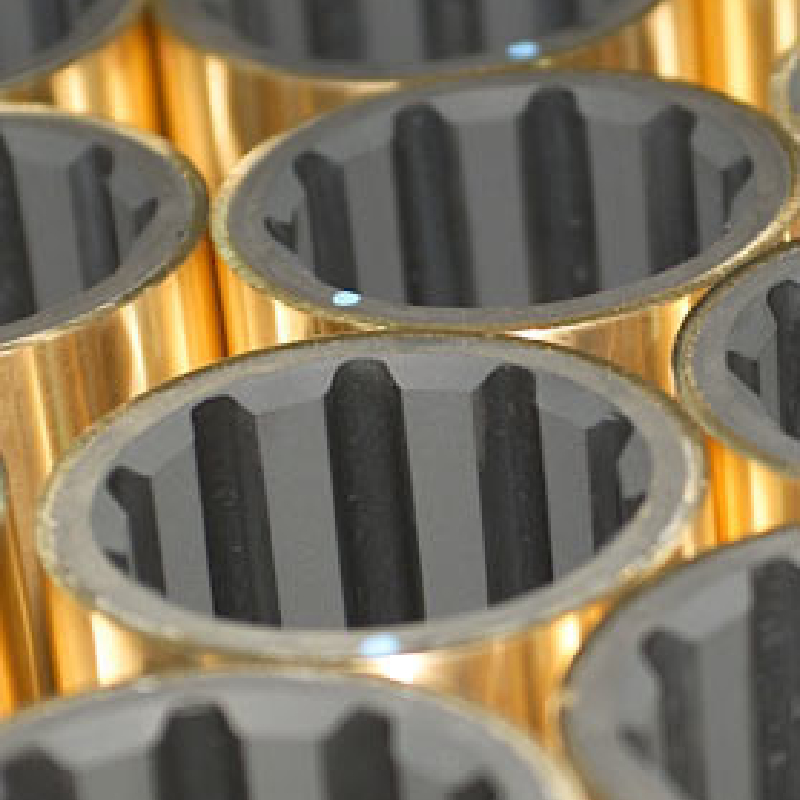

Sealing rings for gaskets

In automotive engineering, gasket rings ensure engine oil and coolant stay where they should, preventing costly damage and potential accidents In automotive engineering, gasket rings ensure engine oil and coolant stay where they should, preventing costly damage and potential accidents

In automotive engineering, gasket rings ensure engine oil and coolant stay where they should, preventing costly damage and potential accidents In automotive engineering, gasket rings ensure engine oil and coolant stay where they should, preventing costly damage and potential accidents gasket rings.

Installation and maintenance of gasket rings are equally important. Incorrect installation can lead to leaks, while neglecting regular checks can result in premature failure. It's essential to understand the specific gasket's properties and follow proper handling procedures to maximize its lifespan.

Innovations in gasket ring technology continue to push the boundaries of performance. New materials, such as composite and ceramic, offer enhanced resistance to corrosion and extreme temperatures. Additionally, 3D printing has opened doors to custom-designed gaskets that perfectly fit irregular or complex geometries.

In conclusion, gasket rings are the unseen champions of the engineering world, silently securing seals and preventing disasters. Their importance cannot be overstated, as they contribute significantly to the efficiency, safety, and longevity of countless systems. As technology advances, so too will the capabilities of these humble yet vital components, further solidifying their position in industrial sealing solutions.

gasket rings.

Installation and maintenance of gasket rings are equally important. Incorrect installation can lead to leaks, while neglecting regular checks can result in premature failure. It's essential to understand the specific gasket's properties and follow proper handling procedures to maximize its lifespan.

Innovations in gasket ring technology continue to push the boundaries of performance. New materials, such as composite and ceramic, offer enhanced resistance to corrosion and extreme temperatures. Additionally, 3D printing has opened doors to custom-designed gaskets that perfectly fit irregular or complex geometries.

In conclusion, gasket rings are the unseen champions of the engineering world, silently securing seals and preventing disasters. Their importance cannot be overstated, as they contribute significantly to the efficiency, safety, and longevity of countless systems. As technology advances, so too will the capabilities of these humble yet vital components, further solidifying their position in industrial sealing solutions. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories