sealed trailer wheel bearings

Understanding Sealed Trailer Wheel Bearings

When it comes to maintaining the health and performance of your trailer, one of the most critical components to consider is the wheel bearing. Specifically, sealed trailer wheel bearings have gained popularity among trailer owners due to their numerous advantages. This article delves into the features, benefits, and maintenance of sealed trailer wheel bearings.

What Are Sealed Trailer Wheel Bearings?

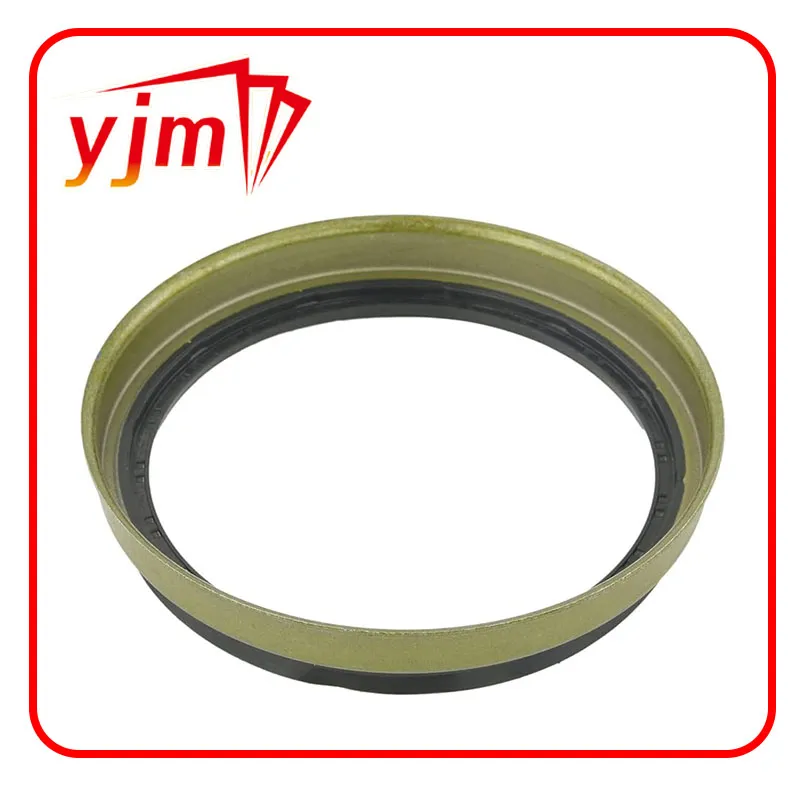

Sealed trailer wheel bearings are specially designed units that allow for smooth wheel rotation while reducing friction and wear. Unlike traditional bearings that require frequent lubrication, sealed bearings come pre-greased and sealed within a protective housing. This design prevents dirt, water, and other contaminants from entering the bearing, which can lead to premature failure.

Advantages of Sealed Trailer Wheel Bearings

1. Reduced Maintenance One of the most appealing benefits of sealed wheel bearings is the significant reduction in maintenance. Since they come pre-greased and sealed, there is no need for routine repacking with grease, which can be a time-consuming task for trailer owners. This feature is particularly advantageous for those who may not have the time or expertise to perform regular maintenance.

2. Extended Lifespan Sealed bearings are designed to withstand harsh conditions, including exposure to water, dirt, and debris. Their sealed design helps keep lubricants in and contaminants out, which contributes to a longer lifespan. Many manufacturers provide warranties that reflect the confidence in the durability of these bearings.

3. Improved Performance The efficient design of sealed trailer wheel bearings reduces friction, which enhances the overall performance of the trailer. This can lead to better fuel efficiency, especially in towing situations. Furthermore, the smooth rotation provided by high-quality sealed bearings can result in improved handling and stability during travel.

4. Simplicity of Installation Sealed bearings are typically easier to install than traditional bearings since they do not require additional tools or processes for greasing. For DIY enthusiasts, this can mean quicker installation times and less mess during the process.

sealed trailer wheel bearings

5. Cost-Effective While the initial cost of sealed trailer wheel bearings may be higher than traditional bearings, the long-term savings in maintenance and replacement costs make them an economical choice for many trailer owners. Their durability and reduced need for servicing can offset the upfront investment over time.

Maintenance Tips for Sealed Trailer Wheel Bearings

Though sealed trailer wheel bearings require less maintenance than traditional bearings, it’s still essential to check them periodically to ensure optimal performance. Here are some tips

- Regular Inspections Inspect the bearings and wheels for any signs of wear, excessive heat, or unusual noises. If you notice anything alarming, it’s essential to investigate further or consult a professional.

- Check the Seal Make sure that the seal is intact. A compromised seal can allow moisture and contaminants to enter the bearing, leading to premature failure.

- Monitor Temperature During or after towing, feel the wheel hub for excessive heat. Overheating can indicate issues with the bearing or that it's time for inspection.

Conclusion

Sealed trailer wheel bearings provide a host of advantages that make them an excellent choice for trailer owners looking for reliability and performance. Their low-maintenance nature, extended lifespan, and improved performance characteristics make them a worthwhile investment. By understanding the benefits and maintaining these components properly, trailer owners can ensure smooth travels and enhanced safety on the road. Whether for leisure or heavy-duty hauling, sealed trailer wheel bearings play a crucial role in keeping your trailer in prime condition.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories