Exploring the Features and Benefits of Sealed Trailer Hub Systems for Enhanced Performance

Understanding Sealed Trailer Hubs Importance and Benefits

Sealed trailer hubs are vital components of trailers used in a wide range of industries, including transportation, agriculture, and recreational vehicles. These hubs serve as the connection point between the trailer’s axle and the wheels, allowing for smooth rotation and proper load-bearing capacity. Sealed design refers to a construction that is intended to keep contaminants, such as dirt, moisture, and debris, from entering the hub assembly, ensuring optimal performance and longevity.

One of the main advantages of sealed trailer hubs is their durability. The sealed nature of the hub reduces the risk of contamination that can lead to wear and tear on essential components, such as bearings. In standard hubs, exposure to dust, water, and other environmental elements can quickly degrade performance, resulting in frequent repairs or replacements. With sealed hubs, the protection afforded by the design means that they are less susceptible to these external factors, making them a preferred choice for many trailer applications.

Maintenance is another key consideration when it comes to trailer hubs. Conventional hubs often require regular grease checks and repacking, which can be time-consuming and labor-intensive. Sealed trailer hubs, on the other hand, are pre-greased and designed to remain maintenance-free for extended periods. This not only saves time and effort for operators but also reduces the risk of improper servicing, which can lead to premature failure. Operators can focus on more critical aspects of their work rather than routine maintenance, ultimately increasing productivity.

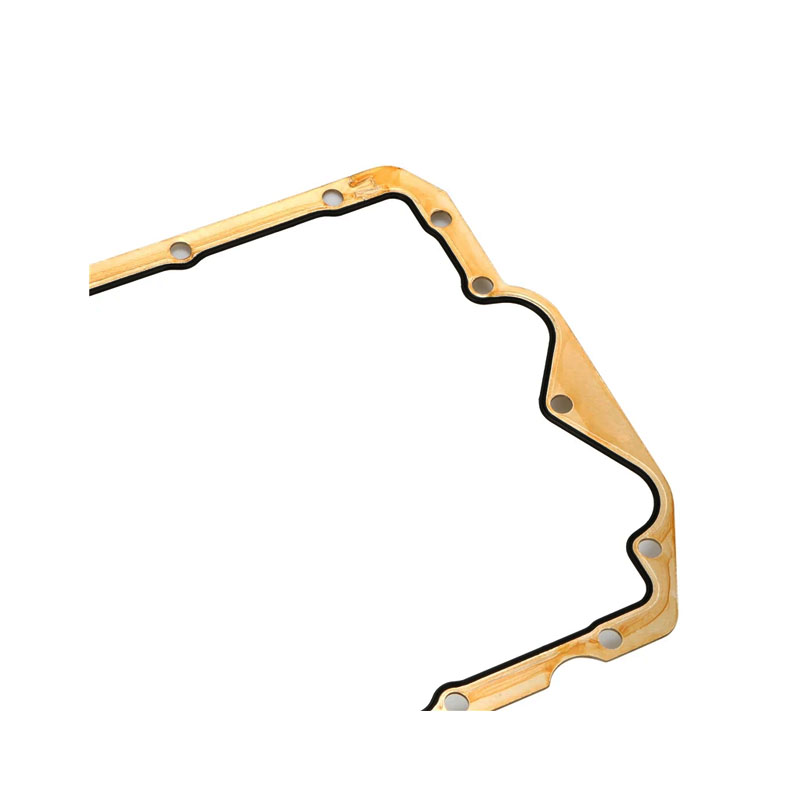

sealed trailer hub

In terms of performance, sealed trailer hubs contribute significantly to the overall efficiency of the trailer. The sealed design minimizes friction between moving parts, allowing for smoother wheel rotation. This can lead to improved fuel efficiency, especially in large transport setups, as less energy is expended in overcoming resistance. Furthermore, reduced friction also translates to lower operating temperatures, which diminishes the likelihood of thermal damage to the bearings over time.

Another important aspect is the safety factor associated with sealed trailer hubs. Because these hubs maintain their integrity against contaminants, they provide reliable braking performance and wheel stability. This is particularly crucial when transporting heavy loads or driving in challenging conditions, such as inclement weather or off-road environments. The reliability of sealed hubs enhances the overall safety of the trailer, providing peace of mind to both operators and those sharing the road.

In conclusion, sealed trailer hubs represent a practical and efficient solution for trailer operations across various applications. Their durability, low maintenance requirements, enhanced performance, and safety features make them an excellent choice for anyone looking to optimize their trailer’s functionality. As the demand for reliable transport solutions continues to grow, investing in high-quality sealed trailer hubs can lead to significant long-term benefits, ensuring that trailers remain reliable and efficient in their operations. By focusing on this essential component, operators can enhance their operational efficiency, safety, and ultimately, their bottom line.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories