Understanding the Benefits of Sealed Trailer Bearings for Optimal Performance and Longevity

Understanding Sealed Trailer Bearings The Key to Smooth Towing

When it comes to maintaining trailers, one of the most crucial components that often gets overlooked is the trailer bearings. Specifically, sealed trailer bearings have gained popularity among trailer owners due to their numerous advantages. Understanding their function, benefits, and maintenance can help you ensure a smoother towing experience.

What Are Sealed Trailer Bearings?

Sealed trailer bearings are specialized components designed to facilitate the smooth rotation of the trailer wheels. Unlike traditional bearings that require regular lubrication, sealed bearings come pre-packed with grease and are housed in a sealed unit. This design prevents contaminants, such as dirt and water, from entering the bearing assembly, significantly reducing the risk of damage and wear.

Benefits of Sealed Trailer Bearings

1. Reduced Maintenance One of the most significant advantages of sealed trailer bearings is the reduction in maintenance requirements. Since these bearings are pre-greased and sealed, they do not require regular greasing like their unsealed counterparts. This feature is especially beneficial for those who use their trailers infrequently or for long periods, as it eliminates the hassle of periodic maintenance.

2. Enhanced Longevity The sealed design of these bearings plays a critical role in their longevity. By keeping contaminants out and retaining the grease inside, sealed bearings can last much longer than open versions. This means fewer replacements over time, ultimately saving money and making trailer ownership more convenient.

3. Smooth Operation Sealed trailer bearings are engineered to minimize friction during operation. This smooth functionality not only makes towing easier but also improves overall fuel efficiency. Reduced resistance means that your vehicle will expend less energy while towing, leading to potential savings on fuel costs.

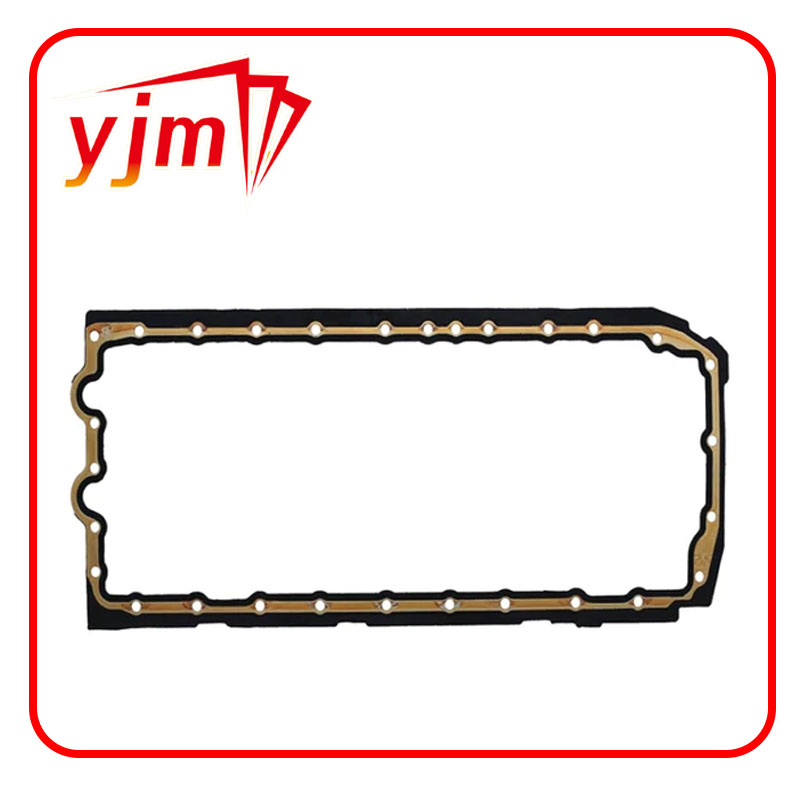

sealed trailer bearings

4. Weather Resistance Sealed bearings offer superior protection against the elements. Whether you’re driving in rain, snow, or through dusty roads, the sealed nature of these bearings ensures they remain operational regardless of weather conditions. This means less worry about performance issues related to environmental factors.

5. Noise Reduction Another advantage of sealed trailer bearings is their ability to reduce noise. Many trailer owners report that with sealed bearings, they experience much quieter operation compared to traditional bearing systems. This is particularly beneficial for long-haul trips where comfort and low noise levels contribute to a better driving experience.

Common Issues and Considerations

While sealed trailer bearings offer numerous benefits, they are not entirely maintenance-free. It’s essential to periodically inspect them for signs of wear or damage, such as unusual noises or vibrations while towing. If you notice any issues, it’s crucial to address them promptly before they lead to more severe problems.

Another consideration is the choice between sealed and unsealed bearings. While sealed bearings provide numerous advantages, unsealed bearings might still be preferred in specific scenarios, particularly where they can be easily accessed and frequently maintained.

Conclusion

In summary, sealed trailer bearings are an excellent investment for anyone looking to optimize their trailer's performance. They offer reduced maintenance needs, enhanced longevity, and weather resistance, making them suitable for various towing environments. Whether you are a casual user or a frequent traveler, considering sealed trailer bearings can significantly enhance your towing experience by providing smoother operation and giving you peace of mind on the road. Regular inspections and timely replacements will ensure these bearings continue to perform at their best, allowing you to enjoy your journeys without the worry of mechanical failures.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories