seal cassette

Understanding Seal Cassettes Functions and Applications

In recent years, seal cassettes have gained significant importance across various industries. These specialized components are crucial for ensuring airtight seals in numerous applications, from aerospace to consumer goods. The seal cassette is designed to provide reliable and durable sealing, making it an essential part of machinery and equipment where prevention of leakage is paramount. This article delves into the functionality, construction, and applications of seal cassettes.

What is a Seal Cassette?

A seal cassette is a prefabricated sealing unit that often contains a combination of materials designed to withstand high pressure and temperature conditions. Typically, it comprises a series of elastomeric seals contained within a protective framework or housing. By designing a modular unit like a seal cassette, manufacturers facilitate easier installation and replacement, which results in reduced downtime and maintenance costs.

Construction and Materials

Seal cassettes are usually made from a variety of high-performance materials, including rubber, silicone, PTFE (Polytetrafluoroethylene), and metals. The choice of material significantly influences the cassette's performance characteristics, such as resistance to chemicals, temperature stability, and overall durability.

1. Elastomeric Materials Commonly used elastomers can compress and return to their original shape, providing a strong barrier against leaking fluids. These materials can tolerate slight movements in machinery without losing their sealing abilities.

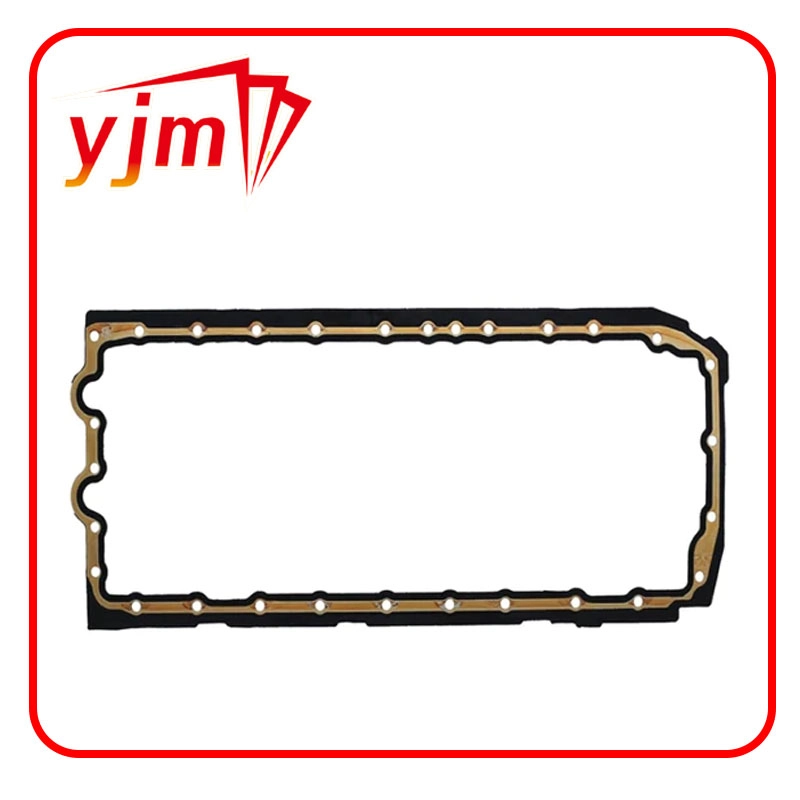

2. Metal Components Some seal cassettes may feature metal components for added strength or thermal conductivity. For instance, metallic gaskets might be used in applications involving high temperatures or aggressive chemicals.

3. Composite Structures Advanced seal cassettes often utilize composite structures, combining different materials to optimize performance characteristics for specific applications.

Functions of Seal Cassettes

seal cassette

Seal cassettes serve several vital functions

- Prevention of Fluid Leakage They are primarily designed to prevent the escape of liquids or gases, protecting sensitive components and ensuring operational efficiency. - Protection against Contaminants Seal cassettes help shield internal components from dirt, moisture, and other contaminants that could compromise machinery integrity. - Enhanced Performance By providing an effective sealing mechanism, seal cassettes help maintain pressure differentials, which are critical for optimal machine performance in many sectors.

Applications of Seal Cassettes

The versatility of seal cassettes allows them to be applied in various industries

1. Aerospace In the aerospace sector, seal cassettes are essential for ensuring airtight and leak-proof seals in aircraft components, such as fuel systems and hydraulic systems. Given the high-stakes nature of aviation, these seals must perform reliably under extreme conditions.

2. Automotive The automotive industry uses seal cassettes extensively, particularly in areas that require robust sealing solutions to prevent fluid leaks from engines, transmissions, and cooling systems.

3. Consumer Products In everyday consumer products like appliances and packaging, seal cassettes play a crucial role in maintaining product integrity, extending shelf life, and ensuring efficient operation.

4. Chemicals and Pharmaceuticals Seal cassettes are vital in industries that handle hazardous materials. They provide a secure barrier to prevent leaks of corrosive chemicals or contamination of pharmaceutical products.

Conclusion

Seal cassettes are an integral part of modern machinery and product design, enabling reliable and efficient operations across a range of applications. Their unique construction and the variety of materials used ensure that they can withstand the rigorous demands of different environments. As industries continue to innovate, the importance of seal cassettes will undoubtedly grow, underscoring their role in advancing technology and enhancing safety in operations. Emphasizing the need for proper selection, installation, and maintenance of these components is essential to ensure they perform optimally, ultimately contributing to more sustainable and efficient industrial practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories