Seal Specification 29x44x7 for Optimal Performance and Durability in Various Applications

The Significance of Seal 29x44x7 Understanding its Role in Machinery and Industry

In the world of machinery and industrial applications, seals play a crucial role in ensuring the efficiency, reliability, and longevity of various systems. Among the myriad of seals available, the seal labeled as 29x44x7 is particularly noteworthy. This designation refers to the seal's dimensions 29 mm inner diameter, 44 mm outer diameter, and a thickness of 7 mm. Understanding the importance of this seal involves delving into its applications, types, materials, and maintenance practices.

Applications of Seal 29x44x7

The 29x44x7 seal finds its primary usage in rotary applications, particularly in electric motors, pumps, gearboxes, and other machinery where shaft rotation is prevalent. Its ability to prevent the leakage of fluids, such as lubricants and hydraulic fluids, while keeping contaminants out is essential for maintaining the operational integrity of equipment. In pump assemblies, for instance, a reliable seal ensures that the pumping efficiency is not compromised due to fluid leaks. In gearboxes, it protects against dirt and moisture, which can lead to increased wear and tear.

Types of Seals

Seals come in various types, and the 29x44x7 seal can be categorized primarily into two groups radial seals and axial seals. Radial seals, or lip seals, are designed to fit tightly into a housing, making them ideal for stopping fluids from escaping around rotating shafts. Axial seals, on the other hand, are used in applications with linear movement, providing a static seal along the axis of a component.

The 29x44x7 seal is predominantly used as a radial seal, often composed of elastomers or rubber-like materials that provide flexibility and resilience. In some cases, these seals incorporate metal components to enhance structural integrity.

Materials Used

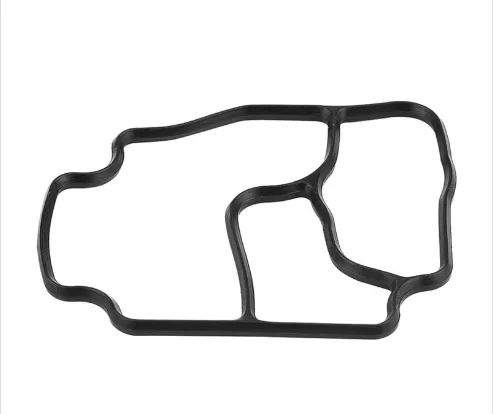

seal 29x44x7

The longevity and effectiveness of a seal depend significantly on the materials used in its manufacturing. The most common materials for seals like the 29x44x7 include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone. NBR is resilient against oils and fuels, making it suitable for automotive applications. FKM, known for its high-temperature and chemical resistance, is often used in more demanding environments where exposure to harsh chemicals is inevitable. Silicone, with its excellent temperature resilience, is utilized in applications that experience extreme temperature fluctuations.

Maintenance and Replacement

To prolong the life of components utilizing the 29x44x7 seal, it’s essential to implement regular maintenance practices. Regular inspections can help identify any signs of wear or degradation, such as cracks, hardening, or leaks. If these issues are detected, timely replacement is vital to avoid more severe damage to machinery.

When replacing seals, it is crucial to ensure that the new seal matches the original specifications. Not only should the dimensions remain consistent, but the material must also be appropriate for the specific application. Using the wrong seal can lead to premature failure and costly downtime.

Conclusion

The 29x44x7 seal is more than just a small component; it plays a vital role in the function and efficiency of various mechanical systems. Understanding its applications, types, materials, and maintenance practices can significantly influence the performance and durability of machinery.

With proper consideration and care, the seal can provide years of reliable service, safeguarding against fluid leakage and contamination. In an industry where downtime can be costly, ensuring that every component is functioning optimally is essential, and the seal 29x44x7 stands as a testament to the importance of seemingly simple parts that contribute to complex machinery systems. As technology continues to evolve, so too will the design and materials of seals, but the fundamental role they play in protecting and enhancing machine functionality remains unchanged.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories