seal 18.9 x30x5

Understanding Seal 2018.9 x 30 x 5 The Importance of Seals in Mechanical Applications

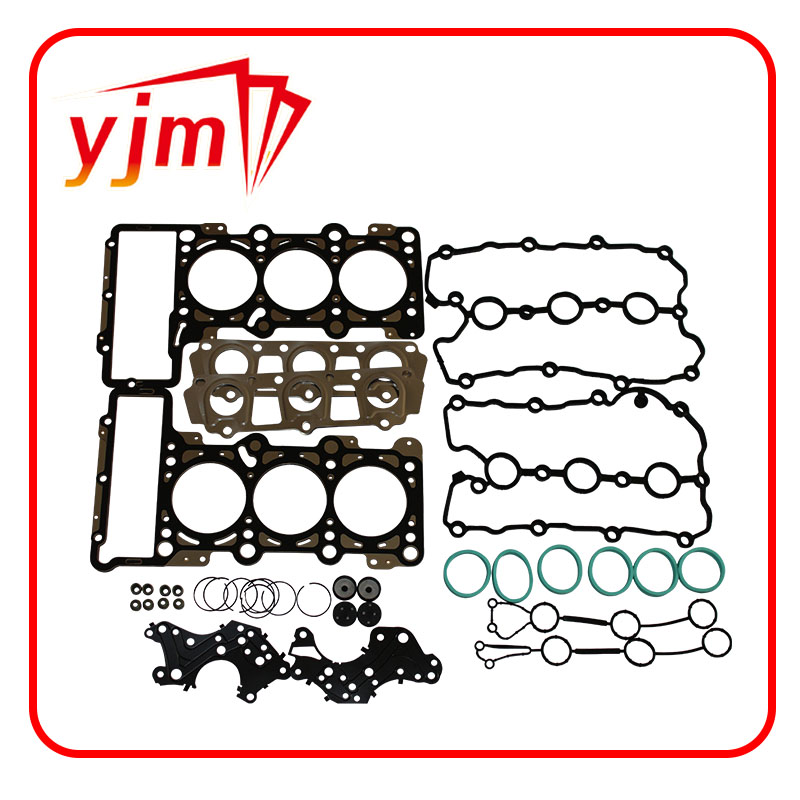

Seals are integral components in various mechanical systems, playing a crucial role in preventing leaks, maintaining pressure, and ensuring the overall efficiency of machinery. One particular designation that has gained attention in engineering and manufacturing is Seal 2018.9 x 30 x 5. In this article, we will explore what this designation means, its applications, and the significance of seals in mechanical systems.

What Does Seal 2018.9 x 30 x 5 Mean?

The designation Seal 2018.9 x 30 x 5 provides specific information about the seal's dimensions and possibly its material. The numbers indicate the size of the seal 2018.9 can refer to the outer diameter, while 30 x 5 could denote the inner diameter and cross-sectional height, respectively. Understanding these dimensions is crucial when selecting a seal for a specific application, as an improper size can lead to inefficiencies and potential equipment failure.

Applications of Seals

Seals are used in numerous applications across various industries, including automotive, aerospace, and manufacturing. In engines, for instance, seals are vital for preventing oil leaks, which can lead to serious performance issues and environmental hazards. In hydraulic systems, seals help maintain pressure, ensuring that fluids are contained within the system for optimal function. Moreover, seals are crucial in everyday appliances, such as refrigerators and air conditioners, helping to prevent the loss of refrigerant and keeping the system efficient.

Types of Seals

Seals can be classified into several categories based on their design and functionality. Common types include

1. O-Rings These are circular seals that fit snugly in grooves and prevent the escape of fluids. O-rings are commonly made from elastomeric materials, providing flexibility and durability.

2. Lip Seals Often used in rotary applications, lip seals have a lip that provides a tight contact surface to prevent leaks, particularly in applications where shafts rotate.

seal 18.9 x30x5

3. Gasket Seals Gaskets are flat seals used to fill the space between two or more mating surfaces, providing a tight seal to prevent the escape of fluids or gases.

4. Mechanical Seals Common in pumps and compressors, these seals provide a robust barrier against leakage between rotating and stationary parts.

Materials Used in Seals

The materials from which seals are made greatly influence their performance. Common materials include

- Rubber Known for its elasticity and resistance to wear, rubber is often used for O-rings and lip seals. - PTFE (Teflon) This material boasts excellent chemical resistance and low friction, making it ideal for high-temperature and corrosive applications. - Metallic materials Used in more demanding applications, metallic seals can withstand extreme pressures and harsh environments.

Importance of Proper Seal Selection

Selecting the right seal, such as the Seal 2018.9 x 30 x 5, is crucial for ensuring the reliability of mechanical systems. Factors to consider when choosing a seal include the operating temperature, pressure, and the type of fluid involved. An inappropriate seal can lead to failures, increased maintenance costs, and even safety hazards.

Conclusion

In conclusion, seals play a vital role in the smooth operation of many mechanical applications. Understanding the specifications, such as those indicated in the designation Seal 2018.9 x 30 x 5, can help engineers and technicians select the appropriate seal for their needs. With the right seal in place, systems can operate efficiently, safely, and reliably, preventing leaks and extending the life of machinery. As technology continues to advance, the importance of high-quality seals will only increase, highlighting the need for ongoing research and development in this critical area of engineering.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories