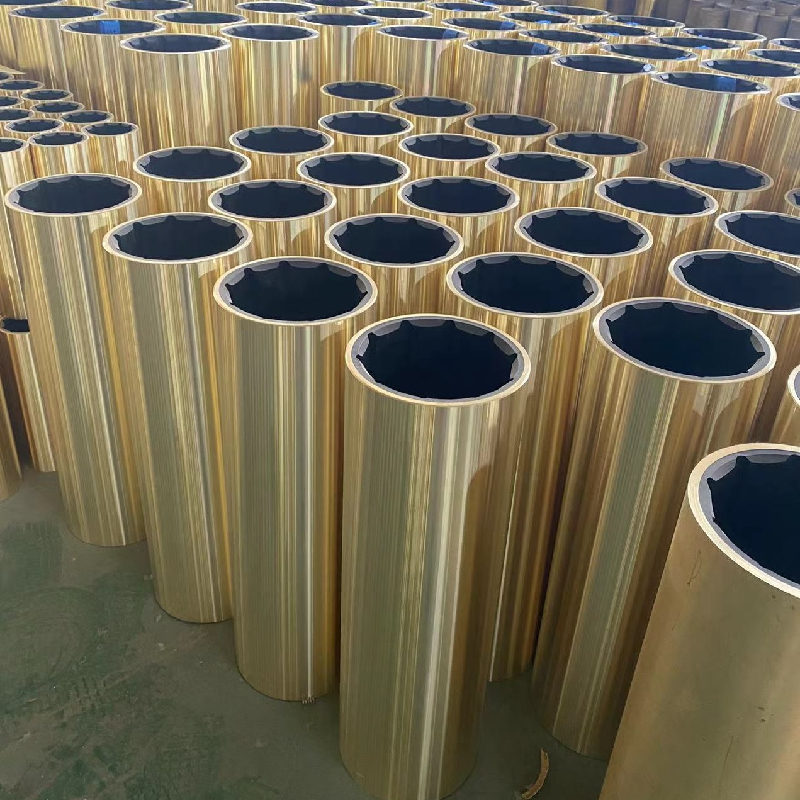

rudder shaft bearing

Understanding Rudder Shaft Bearings Critical Components in Marine Engineering

In the world of marine engineering, the efficiency and reliability of a vessel's steering system are paramount. At the heart of this system is the rudder shaft bearing, a crucial component that ensures smooth and effective steering. This article delves into the importance, function, and maintenance of rudder shaft bearings, emphasizing their role in maritime safety and performance.

The Role of Rudder Shaft Bearings

Rudder shaft bearings are designed to support the rudder shaft, which connects the rudder blade to the steering mechanism. This connection is vital for maneuvering a ship, allowing it to change direction and maintain stability in the water. The bearing is typically located within the ship’s hull or on the rudder itself, creating a secure pivot point for the rudder's movement.

These bearings must handle significant loads and stresses, including the weight of the rudder and the forces exerted during maneuvers. Consequently, they are engineered to withstand harsh marine environments, including exposure to saltwater, high pressure, and varying temperatures.

Types of Rudder Shaft Bearings

There are several types of rudder shaft bearings, each designed for specific applications and conditions. The most common types include

1. Bushings These are simple, cylindrical bearings made from materials like bronze or composite materials. They provide a low-friction surface for the rudder shaft to rotate against.

2. Ball Bearings These bearings use steel balls to reduce friction and improve the smoothness of the rudder’s operation. They are often used in high-performance vessels where precision maneuverability is required.

Each type has its advantages and is chosen based on the specific requirements of the vessel, including size, weight, and intended use.

rudder shaft bearing

Importance of Maintenance

Maintenance of rudder shaft bearings is critical to ensure their longevity and functionality. Regular inspections should be performed to detect any signs of wear, corrosion, or damage. Key aspects of maintenance include

- Lubrication Proper lubrication reduces friction and wear. Most bearings require regular grease application, especially in high-stress environments.

- Alignment Checks Misalignment can lead to increased wear and premature failure of bearings. Regular checks ensure that the rudder shaft aligns with the rudder post correctly.

- Damage Assessment Frequent inspections should focus on detecting any signs of cracking, pitting, or other forms of damage. Early detection can prevent more significant issues that could compromise the vessel's steering ability.

- Replacement Bearings have a finite lifespan and may need to be replaced. Operators should be familiar with the signs that indicate a bearing’s need for replacement, such as excessive noise or vibrations during operation.

The Impact of Failure

The failure of a rudder shaft bearing can have serious consequences. It can lead to loss of steering control, which poses a severe safety risk not only to the vessel and its crew but also to other vessels in the vicinity. Additionally, failure can result in costly repairs and extended downtime, impacting the vessel's operational capabilities.

To mitigate these risks, ship owners and operators must prioritize preventive maintenance and be equipped with the knowledge to conduct timely inspections and necessary repairs. Investing in high-quality materials and components for rudder shaft bearings can also enhance reliability and performance.

Conclusion

Rudder shaft bearings are integral to the safe and efficient operation of marine vessels. Understanding their importance, types, and maintenance requirements is crucial for marine engineers and ship operators. By prioritizing the upkeep of these components, operators can ensure their vessels remain maneuverable and safe while navigating the world’s waters. As maritime technology continues to advance, ongoing research and development in bearing materials and designs will likely yield even more robust solutions, further enhancing the safety and performance of maritime navigation.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories