Understanding Rudder Shaft Bearings for Marine Propulsion Systems and Their Critical Role

Understanding Rudder Shaft Bearings Importance and Function

Rudder shaft bearings are a crucial component in the marine industry, specifically in the operation and maneuverability of boats and ships. These bearings play a significant role in the overall functionality of the vessel's steering system, ensuring smooth and efficient navigation through both calm and turbulent waters. This article delves into the importance, function, and maintenance of rudder shaft bearings.

The Role of Rudder Shaft Bearings

Rudder shaft bearings secure the rudder shaft to the hull of the vessel, allowing it to pivot and direct the movement of the ship. When the helm is turned, the rudder changes its angle, altering the water flow and, consequently, the direction in which the vessel travels. Bearings are essential in this mechanism as they support the weight of the rudder and reduce friction during its movement. This efficiency is critical for the responsive handling of the vessel, especially in demanding sea conditions.

There are primarily two types of rudder shaft bearings plain bearings and roller bearings. Plain bearings use a smooth surface for the shaft to rotate against, often made from materials such as bronze, plastic, or a composite material. On the other hand, roller bearings consist of cylindrical rollers that minimize friction further but may require more complex installation and maintenance. The choice between these types typically depends on the size of the vessel and the materials available.

Importance of Material Selection

The materials used for rudder shaft bearings are paramount to their performance and durability

. Bearings must withstand harsh marine environments, which include exposure to saltwater, varying temperatures, and heavy loads. Corrosion resistance is essential; hence, many manufacturers opt for stainless steel or specially treated composites that offer both strength and longevity.Additionally, the selection of the lubrication type is vital. Bearings may be lubricated with grease, oil, or even self-lubricating materials to ensure they operate smoothly over time. Proper lubrication minimizes wear and tear, prevents overheating, and extends the life of the bearing, ultimately enhancing the overall performance of the steering system.

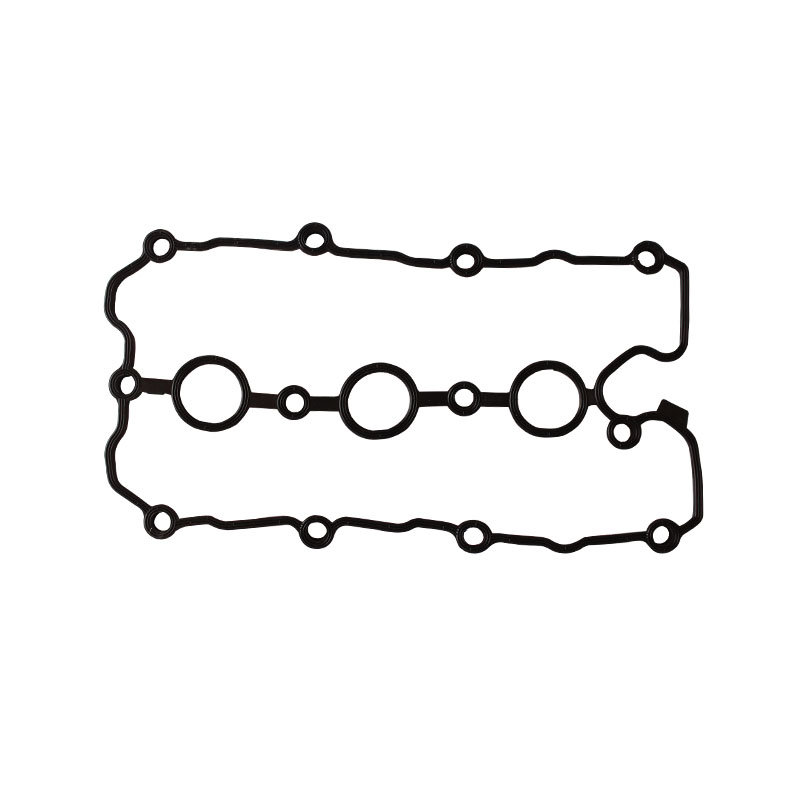

rudder shaft bearing

Maintenance Considerations

Regular maintenance of rudder shaft bearings is crucial in ensuring their optimal performance and longevity. Routine inspections should be conducted to check for signs of wear, corrosion, or any unusual noises that might indicate an underlying issue. Common maintenance tasks include

1. Visual Inspections Regularly check for any physical damage or misalignment of the rudder shaft and bearings.

2. Lubrication Ensure that the bearings are adequately lubricated as per manufacturer specifications to reduce friction and wear.

3. Alignment Checks Proper alignment of the rudder shaft is essential. Misalignment can lead to uneven wear and potential failure of the bearing system.

4. Replacement of Worn Parts Bearings do have a lifespan, and once they start showing significant wear, it is crucial to replace them to avoid more extensive damage.

Conclusion

Rudder shaft bearings are integral to the safe and efficient operation of marine vessels. Understanding their function, the importance of material selection, and ongoing maintenance can significantly impact the performance and safety of a ship. By ensuring that these components are properly maintained, boat owners and operators can enhance their vessel's maneuverability, leading to safer navigation in various maritime conditions. As the marine industry continues to evolve, the innovation in bearing design and materials will further improve their efficiency, ensuring that rudder shaft bearings remain a vital part of modern sailing.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories