Alternatives to Rudder Bearings for Improved Navigation Performance

Understanding Rudder Bearings Importance and Functionality in Maritime Navigation

Rudder bearings play a critical role in the safe and efficient operation of maritime vessels. They are integral components of the steering system, contributing to the overall maneuverability and stability of a ship. This article delves into the significance, types, maintenance, and the future of rudder bearings in the context of modern maritime technology.

The Function of Rudder Bearings

Rudder bearings are mechanical components that support the rudder stock, allowing it to pivot freely while transferring steering commands from the helm to the rudder. This pivotal movement is crucial for controlling the direction of the vessel. The efficiency of rudder bearings affects not just navigational precision but also overall vessel performance, particularly when it comes to speed, fuel efficiency, and responsiveness.

The primary role of rudder bearings is to minimize friction, ensuring smooth and consistent movement of the rudder. They are designed to withstand harsh marine environments, such as seawater corrosion, cavitation, and heavy loads that typically occur during navigation. Therefore, the material and design of rudder bearings are engineered to deliver durability and reliability.

Types of Rudder Bearings

There are various types of rudder bearings, each suited for specific conditions and vessel requirements. The most common types include

1. Plain Bearings These are the simplest form of rudder bearings, made from materials like bronze or plastic. They are widely used because of their low friction properties and ease of installation. However, they may require frequent maintenance and replacement.

2. Self-Aligning Bearings Providing the advantage of self-alignment, these bearings can accommodate slight misalignments in the rudder stock, which is particularly useful in larger vessels where precision may be compromised.

3. Roller Bearings Designed to handle heavy loads, roller bearings offer lower friction and increased durability. They are ideal for larger ships that require high-performance capabilities during navigation.

4. Composite Bearings These bearings combine materials like plastic with metal, offering a balance between wear resistance and low friction. They have gained popularity due to their longevity and reduced need for lubrication.

rudder bearings

Maintenance and Inspection

Regular maintenance and inspection of rudder bearings are essential to ensure their longevity and reliability. Over time, factors such as wear, corrosion, and contamination can degrade bearing performance. Operators should implement a routine maintenance schedule that includes

- Visual Inspections Regular visual checks can help identify early signs of wear or damage, allowing for timely interventions.

- Lubrication Proper lubrication is crucial for minimizing friction and preventing wear. Depending on the type of bearing, the frequency and type of lubrication may vary.

- Alignment Checks Ensuring the proper alignment of the rudder and bearings is essential for optimal performance. Misalignment can result in increased wear and reduced efficiency.

- Replacement Bearings should be replaced as needed, based on their condition and performance metrics. Keeping a log of inspections and maintenance actions can aid in determining when replacements are necessary.

Future Developments in Rudder Bearings

As maritime technology continues to advance, so too does the design of rudder bearings. Innovations in materials and engineering are leading to the development of more advanced bearings that are lighter, stronger, and more resistant to environmental factors. The trend towards automation and electronic steering systems also prompts a re-evaluation of bearing designs and their integration with modern navigation systems.

Furthermore, with an increasing emphasis on sustainability and eco-friendliness, manufacturers are exploring biodegradable and recyclable materials for rudder bearings. This shift not only addresses environmental concerns but also enhances the overall efficiency of maritime operations.

Conclusion

Rudder bearings are vital components that directly influence the performance and navigational capabilities of vessels. Understanding their types, maintenance needs, and advancements can significantly impact maritime safety and efficiency. As the industry evolves, continuous innovation will ensure that rudder bearings remain robust and reliable in the face of future challenges. With proper care and attention, these seemingly minor components will continue to play a pivotal role in the safe navigation of our oceans for years to come.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

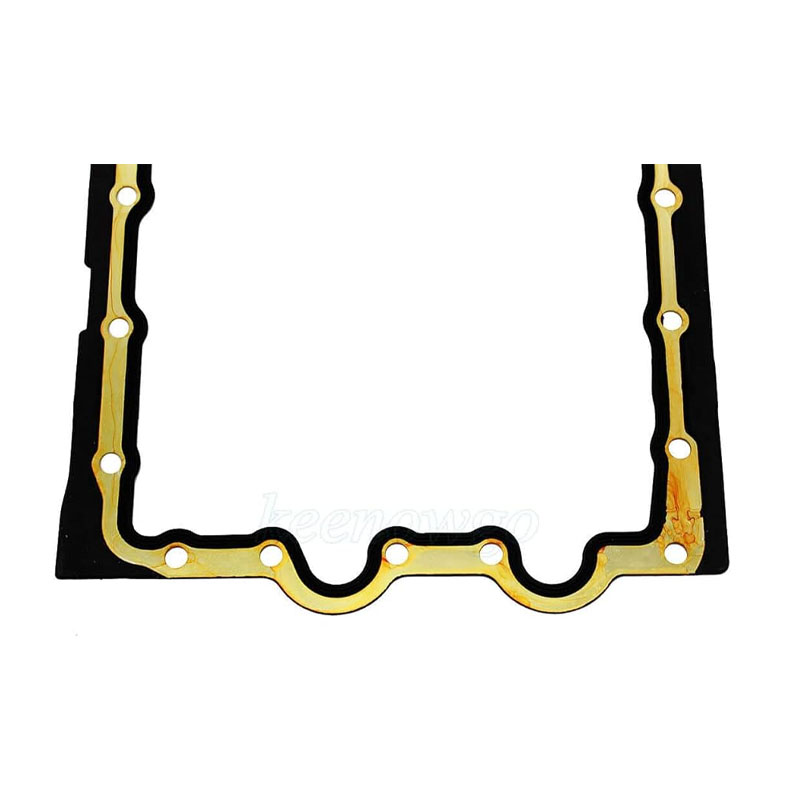

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories