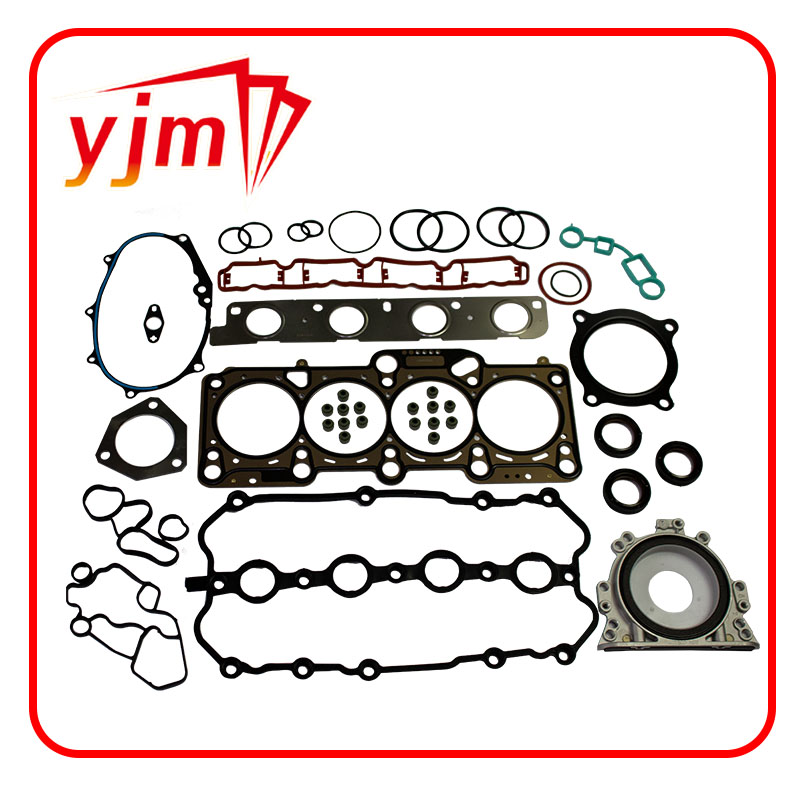

rubber shaft seal

Understanding Rubber Shaft Seals Essential Components for Mechanical Integrity

Rubber shaft seals, also known as rotary shaft seals or lip seals, are crucial components used in various machinery and equipment to prevent leakage of fluids and contaminants. These seals serve as protective barriers, ensuring the proper functioning and longevity of mechanical systems, ranging from automotive engines to industrial machines.

A rubber shaft seal typically consists of a rubber body with a sealing lip that makes contact with the rotating shaft. This design allows for a tight fit while accommodating the shaft's movements. The main purpose of the seal is to prevent hydraulic fluids, oils, or lubricants from escaping the system, while also keeping dust, dirt, and water from entering. This dual action is vital for maintaining the operational efficiency and safety of mechanical systems.

One of the most significant advantages of rubber shaft seals is their versatility

. They can be fabricated from various types of rubber materials, such as nitrile, fluoroelastomer, or silicone, each offering unique properties tailored to specific applications. For instance, nitrile rubber is excellent for petroleum-based fluids, while fluoroelastomers provide superior heat and chemical resistance, making them ideal for harsh environments.rubber shaft seal

The installation and maintenance of rubber shaft seals are relatively straightforward, yet they require precision to ensure a proper fit. Incorrect installation can lead to premature wear or failure, resulting in costly repairs and downtime. Therefore, it is essential to follow manufacturer guidelines and industry standards during installation. Regular inspections can also help in identifying signs of wear, such as cracks or surface degradation, ensuring timely replacements before any significant issues arise.

Moreover, the performance of rubber shaft seals can significantly impact the overall efficiency of a machine. A well-functioning seal reduces friction, which improves energy efficiency and minimizes operational costs. Conversely, a faulty seal can lead to increased maintenance needs and can compromise the machine's integrity.

In conclusion, rubber shaft seals are vital components in various mechanical systems, offering protection against fluid leakage and contamination. Their versatility, combined with proper installation and maintenance practices, ensures that machinery operates smoothly and efficiently. As industries continue to evolve, the importance of these seals will remain paramount, providing reliability and durability in an ever-demanding environment. Understanding the role and functioning of rubber shaft seals can help engineers and technicians make informed decisions that enhance the performance and lifespan of their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories