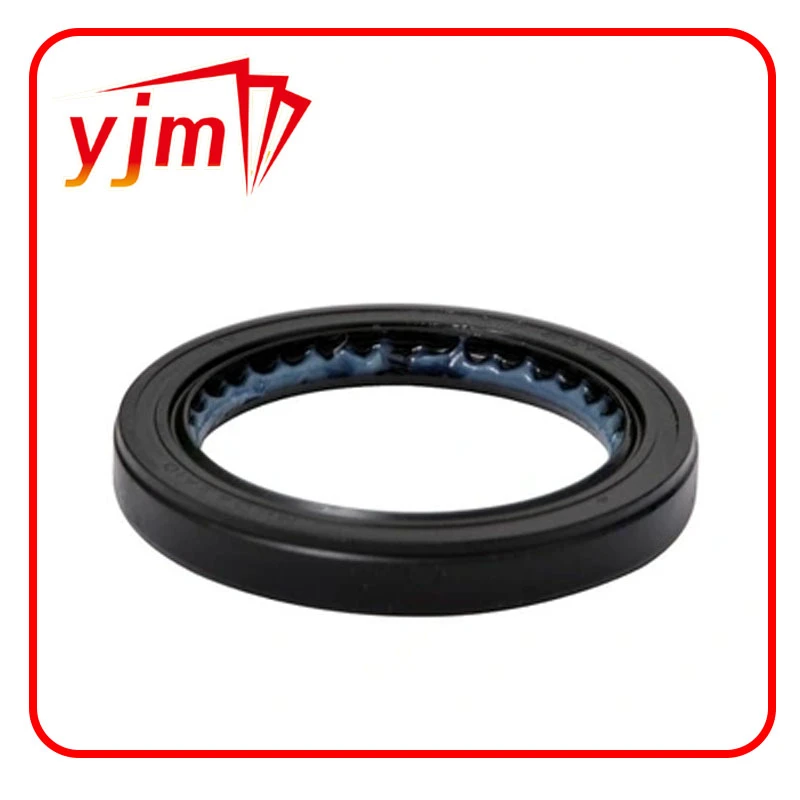

automotive shaft seals

The significance of rubber shaft seals extends beyond efficient mechanical performance; they are also vital for ensuring safety and environmental compliance. For instance, in the food processing industry, rubber shaft seals prevent contamination, thereby meeting strict health and safety regulations. Similarly, in the petrochemical industry, these seals are crucial in preventing hazardous leaks, adhering to environmental standards. Companies that supply rubber shaft seals must uphold authoritative industry standards, ensuring their products meet stringent quality measures. By aligning with recognized standards like ISO 9001 and SAE, these companies demonstrate their commitment to quality and reliability, fostering trust with consumers. This credibility is further reinforced by transparent practices such as providing detailed product specifications, case studies, and customer testimonials. In recent years, advancements in rubber technology have led to the development of seals with enhanced performance characteristics. Researchers are focusing on novel rubber composites that offer improved resistance to wear and tear, extending seal life even under the most challenging conditions. This innovation not only provides economic benefits by reducing replacement costs but also contributes to sustainability by lowering material waste. In conclusion, the rubber shaft seal is a pivotal element in various industrial applications, facilitating efficient and safe operations. Its role in preserving machinery integrity and performance is unmatched, backed by material science advancements and rigorous industry standards. As industries continue to evolve, the need for high-quality, reliable sealing solutions will remain essential, underscoring the timeless relevance of rubber shaft seals in the modern industrial landscape. By understanding and leveraging the full potential of rubber shaft seals, businesses can achieve enhanced operational efficacy, staying a step ahead in competitive markets.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories