Alternative Solutions for Effective Sealing with Rubber Crush Washers and Their Applications

The Importance of Rubber Crush Washers in Mechanical Applications

In the realm of mechanical engineering and manufacturing, ensuring optimal performance and durability of components is paramount. One often-overlooked yet essential component that plays a significant role in securing leak-proof seals and joining parts is the rubber crush washer. Designed specifically for sealing applications, these washers are critical in an array of industries, including automotive, aerospace, plumbing, and machinery.

Rubber crush washers, also known as rubber sealing washers, are typically made from various materials, including natural rubber, neoprene, and silicone. Each material offers distinct advantages, such as resistance to different temperatures, chemicals, and environmental conditions. The design of these washers allows them to compress under load, creating a tight seal that prevents leakage of fluids and gases. This characteristic is particularly useful in applications where traditional metal washers might fail due to vibration or thermal expansion.

One of the most notable benefits of rubber crush washers is their ability to adapt to irregular surfaces. Unlike metal washers that maintain a fixed shape, rubber washers can conform to the surface of the parts they are sealing against, ensuring a more effective seal. This adaptability makes them ideal for use in situations where surfaces may not be perfectly aligned or may change due to thermal or mechanical forces.

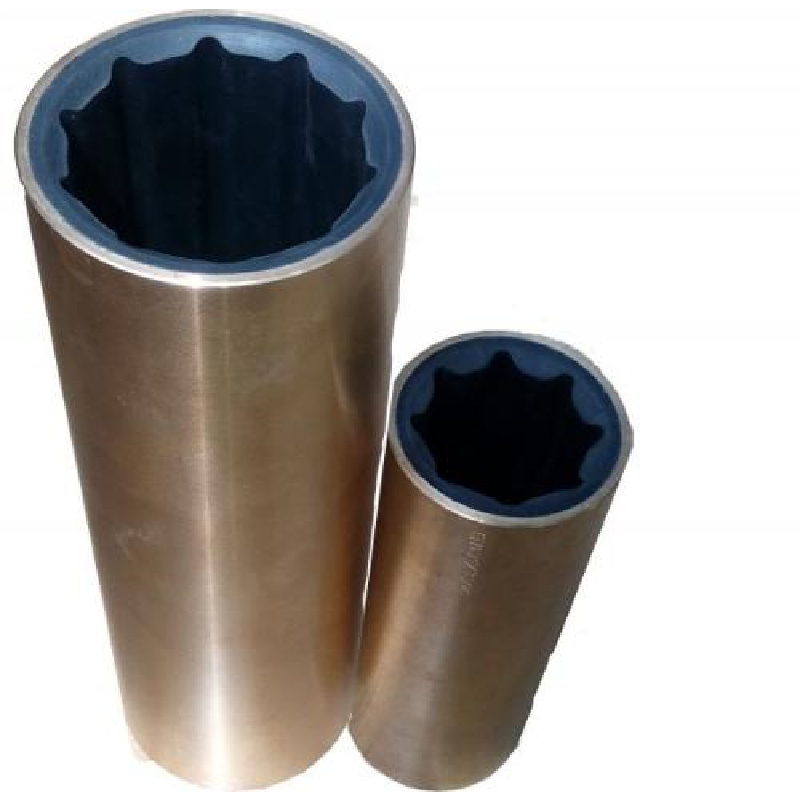

rubber crush washer

In automotive applications, rubber crush washers are often used in oil and coolant systems

. They are strategically placed between components to prevent leaks that could lead to performance issues or even catastrophic failures. In the aerospace industry, where safety and precision are critical, these washers are employed to secure fittings and prevent fluid leakage in high-pressure environments.Aside from their mechanical applications, rubber crush washers are also cost-effective solutions. They are generally inexpensive to produce and can significantly reduce maintenance costs by preventing leaks and associated damages. Regular replacement of worn or damaged washers can extend the lifespan of machine components, thus enhancing overall efficiency.

However, it is essential to select the right type of rubber crush washer for specific applications. Factors such as temperature range, chemical compatibility, and load capacity must be considered to ensure optimum performance. Failure to do so might result in premature failure and leakage, which could have dire consequences in critical systems.

In conclusion, rubber crush washers are vital components that enhance the reliability and efficiency of various mechanical systems. By providing effective sealing solutions across multiple industries, they play an integral role in maintaining the integrity and safety of machinery and equipment. As technology advances, the development of more resilient materials for these washers will continue to contribute to improved performance and longevity in countless applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories