Rubber Crush Washers for Effective Sealing and Leakage Prevention Solutions

The Role of Rubber Crush Washers in Industrial Applications

Rubber crush washers, also known as rubber sealing washers or compression washers, are essential components in many industrial applications. They serve a crucial role in ensuring seals, preventing leaks, and maintaining the integrity of various assemblies, particularly in mechanical and automotive sectors. As technology evolves, the demand for reliable sealing solutions has increased, making rubber crush washers an indispensable part of modern engineering.

What Are Rubber Crush Washers?

Rubber crush washers are typically circular, flat discs made from various rubber materials, including natural rubber, silicone, nitrile, and neoprene. Their primary function is to create a seal between two surfaces when subjected to compression. When installed, these washers deform under pressure, filling gaps and preventing the escape of fluids or gases. This ability to compress makes them highly effective in applications where traditional metal washers might fail due to rigidness and poor sealing capabilities.

Applications in Industry

1. Automotive Industry One of the most common uses of rubber crush washers is in the automotive sector. They are often employed in oil and fuel systems, where a reliable seal is essential to avoid leaks. For example, they can be found in oil pan gaskets, fuel injectors, and various other components that require a tight seal to prevent fluid loss and ensure the safe operation of vehicles.

2. Aerospace In the aerospace industry, where safety and reliability are paramount, rubber crush washers are used in hydraulic systems, fuel systems, and pressure-sensitive applications. These washers help maintain the integrity of seals under varying pressures and temperatures, making them vital for aircraft performance and safety.

3. Plumbing In plumbing applications, rubber crush washers serve to create watertight seals between pipes, fittings, and valves. Their ability to compress makes them suitable for a variety of plumbing fixtures, ensuring that connections remain leak-free over time.

4. Manufacturing Rubber crush washers are also widely used in manufacturing processes involving mechanical assemblies. They can be found in machinery, pumps, and compressors, where they help prevent the leakage of lubricants and other fluids, enhancing operational efficiency and extending the life of equipment.

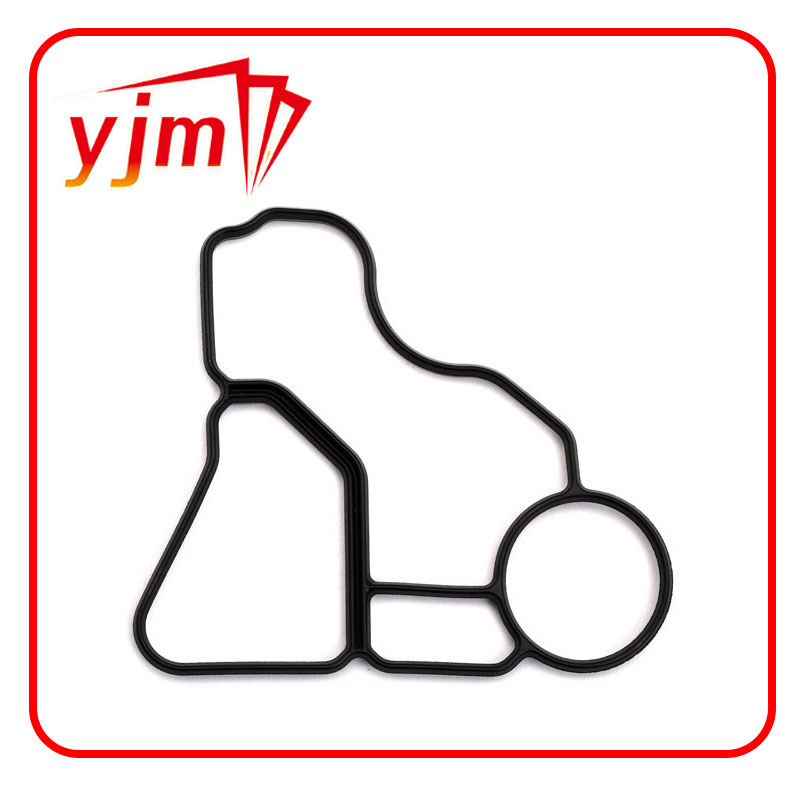

rubber crush washer

Advantages of Rubber Crush Washers

The various benefits of rubber crush washers significantly contribute to their popularity in many applications. Some of the key advantages include

- Flexibility and Compression Unlike metal washers, rubber crush washers can easily deform under pressure, filling in gaps and irregularities between mating surfaces. This helps in creating a secure seal that metal washers cannot achieve.

- Corrosion Resistance Rubber is inherently resistant to many chemicals and environmental factors, making these washers ideal for use in harsh conditions where metal components might corrode or degrade.

- Noise Dampening Rubber has excellent vibration and noise-dampening properties. When used in assembly, rubber crush washers can reduce noise generated by moving parts, contributing to quieter operation in mechanical systems.

- Cost-Effective Rubber crush washers are relatively inexpensive compared to other sealing solutions. Their affordability, combined with their effectiveness, makes them a popular choice for both manufacturers and technicians.

Conclusion

In conclusion, rubber crush washers play a vital role in a wide range of industrial applications, providing reliable sealing solutions that enhance safety, efficiency, and performance. With their unique ability to compress and conform to surface irregularities, they offer advantages that metal washers simply cannot match. As industries continue to evolve and demand higher standards, the importance of rubber crush washers will only grow, highlighting the need for ongoing innovation in materials and manufacturing processes to meet the challenges of modern engineering. Understanding their function and applications is crucial for anyone involved in mechanical design, maintenance, or production, ensuring that systems remain robust and leak-free in an ever-demanding industrial landscape.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories