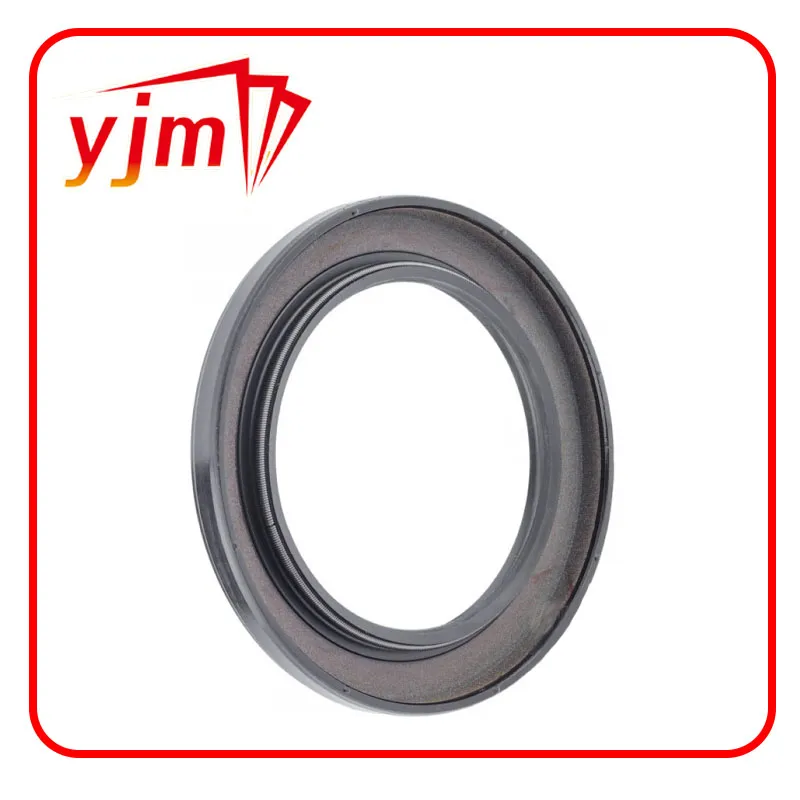

rotating shaft seals

Understanding Rotating Shaft Seals A Key Component in Machinery

Rotating shaft seals are critical components used in various machinery and equipment across numerous industries. Their primary function is to prevent the leakage of fluids, such as oil, grease, or any other lubricants, from the machinery while simultaneously keeping contaminants out. This article will explore the importance, types, applications, and performance factors of rotating shaft seals.

Importance of Rotating Shaft Seals

The significance of rotating shaft seals lies in their role in maintaining the efficiency and longevity of machinery. A well-functioning seal not only prevents fluid leaks but also helps in minimizing friction between moving parts. In doing so, it plays a crucial role in reducing wear and tear, improving energy efficiency, and enhancing overall machine performance. Failure of these seals can lead to significant operational problems, including equipment malfunction, increased maintenance costs, and environmental pollution due to leaks.

Types of Rotating Shaft Seals

Rotating shaft seals come in various types, each designed for specific applications. The most common types include

1. Lip Seals These are among the most widely used seals, characterized by a flexible lip that makes contact with the shaft. Lip seals are effective in retaining lubricants and preventing contaminants from entering the machine.

2. Mechanical Seals Used primarily in pumps and compressors, mechanical seals consist of two flat surfaces that compress against each other to create a tight seal. They are suitable for high-pressure applications and can handle a wide range of temperatures.

3. O-Rings Although not exclusive to rotating shafts, O-rings are commonly used in conjunction with shafts to provide a sealing solution. They are circular in shape and work by compressing between two surfaces to prevent fluid leaks.

4. Slinger Seals These seals are designed to deflect fluid away from the rotating shaft, minimizing splash and leakage. They are often used in conjunction with other sealing methods for added protection.

Applications of Rotating Shaft Seals

Rotating shaft seals are prevalent in numerous applications, including

rotating shaft seals

- Automotive Industry Used in engines, differentials, and transmissions, where they help in retaining lubricants and preventing fluid loss.

- Industrial Machinery In manufacturing equipment, rotating shaft seals protect against dust and debris, ensuring smooth operation.

- Pumps and Compressors In these applications, mechanical seals are widely used to maintain pressure integrity while preventing leaks.

- Aerospace and Marine Seals play a crucial role in engines and turbines, where high performance and reliability are essential.

Performance Factors

Several factors influence the performance of rotating shaft seals

- Material Selection The choice of materials is critical, as it must withstand the operating conditions, such as temperature, pressure, and the type of fluid being sealed.

- Surface Finish The surface finish of the shaft and housing can affect the sealing efficiency. Smoother surfaces tend to enhance the sealing performance.

- Installation Proper installation is vital to ensure an effective seal. Misalignment or improper seating can lead to premature failure.

- Operating Environment The environment in which the machinery operates—such as exposure to chemicals, moisture, or abrasive particles—can significantly impact seal durability and performance.

Conclusion

Rotating shaft seals are indispensable in the realm of machinery, playing a fundamental role in ensuring efficiency, reliability, and longevity. Understanding the different types and their applications, alongside the factors influencing their performance, can significantly enhance machinery operation and maintenance. As technology advances, the design and materials used in producing rotating shaft seals continue to evolve, addressing the ever-changing demands of modern industries. Ensuring the right seal is employed for the right application will ultimately lead to improved performance and reduced operational costs.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories