Innovative Solutions for Enhanced Performance of Rotating Seals in Various Applications

The Importance of Rotating Seals in Modern Engineering

Rotating seals play a crucial role in numerous applications across various industries, including automotive, aerospace, oil and gas, and manufacturing. These seals ensure that fluids and gases do not leak from rotating equipment, contributing to the efficiency and safety of machinery. This article explores the significance of rotating seals, their types, applications, and advancements in technology that are shaping their future.

Understanding Rotating Seals

Rotating seals, often referred to as mechanical seals or dynamic seals, are designed to prevent leakage between stationary and moving components in machinery. Unlike static seals, which maintain a seal at rest, rotating seals are specifically engineered to handle the relative motion between parts, often at high speeds. They can handle various operating conditions, including extreme temperatures, pressures, and aggressive chemical environments.

Types of Rotating Seals

There are several types of rotating seals, each designed for specific applications

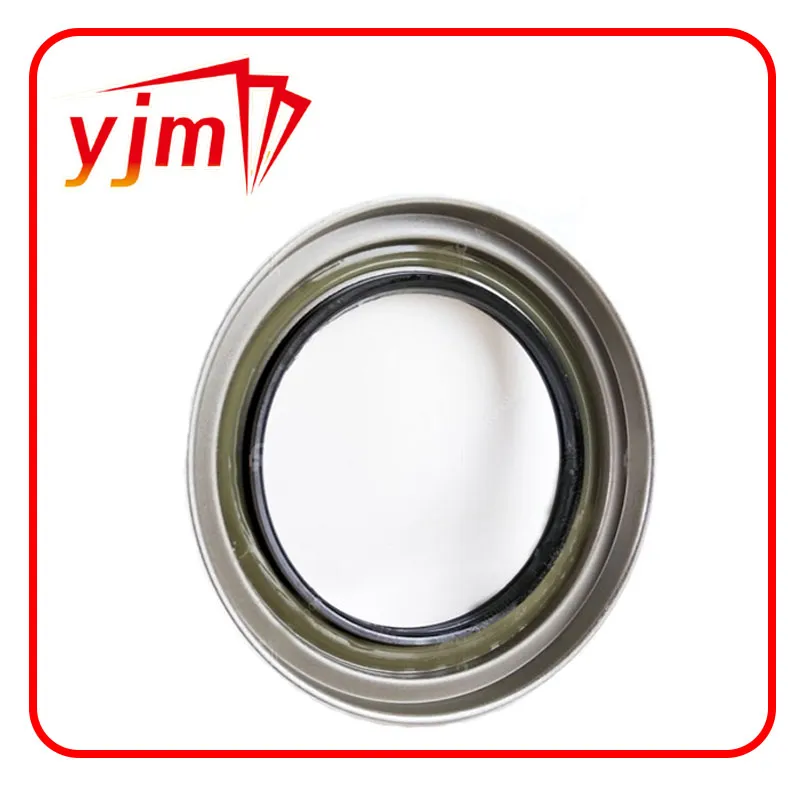

1. Mechanical Seals These are commonly used in pumps and compressors. A mechanical seal consists of two primary components a rotating face and a stationary face. When pressed together, they create a seal that prevents leakage of fluids.

2. Lip Seals Also known as radial seals, lip seals consist of a flexible lip that contacts the shaft to avoid the escape of fluids. They are often used in rotating shafts in automotive applications and in machinery that operates in less demanding conditions.

3. Ball and Roller Bearings While primarily components that support rotating shafts, they also incorporate seals to prevent contamination and retain lubrication. These seals are critical in enhancing the longevity and performance of the bearings.

4. Gasket Seals Although not purely dynamic, gaskets can also play a role in rotating equipment when they are used in conjunction with other sealing technologies to prevent leakage.

Applications of Rotating Seals

Rotating seals are vital in numerous applications

rotating seals

- Automotive Industry In vehicles, rotating seals are found in engines, transmissions, and differentials, where they help maintain oil and fluid integrity

. They reduce friction, enhance performance, and prevent breakdowns.- Aerospace Aircraft engines and hydraulic systems utilize rotating seals to withstand extreme pressures and temperatures while ensuring the safety of flight operations.

- Oil and Gas In oil extraction and processing, rotating seals are essential for preventing leaks of volatile substances and ensuring the safe operation of pipelines and rigs.

- Manufacturing Many machining processes rely on rotating seals to maintain precision and prevent contamination of products. They are used in CNC machines, industrial mixers, and packaging machinery.

Advancements in Rotating Seal Technology

Recent developments in materials science and engineering techniques have significantly enhanced the performance and reliability of rotating seals.

- Material Innovation Modern rotating seals are constructed from advanced materials such as fluoropolymers and ceramic composites. These materials exhibit better resistance to chemicals, heat, and wear, which is essential for extending the lifespan of seals in demanding environments.

- Enhanced Designs Advanced computer modeling and simulation techniques have allowed for the optimization of seal designs. This leads to improved sealing performance and reduced operational costs by minimizing leakage and enhancing efficiency.

- Smart Seals The integration of smart technologies is also emerging in the realm of rotating seals. Sensors embedded within the seals can monitor pressure, temperature, and wear. This data aids in predictive maintenance, allowing for timely interventions before catastrophic failures occur.

Conclusion

As industries continue to evolve, the demand for effective sealing solutions will only grow. Rotating seals are at the forefront of this requirement, playing a vital role in maintaining the integrity and efficiency of machines. With ongoing advancements in materials and technology, the future of rotating seals looks promising. Emphasizing innovation and reliability, these components will remain crucial in ensuring the safe and efficient operation of machines across a wide range of applications. As we continue to innovate, rotating seals will undoubtedly adapt and evolve, meeting the needs of the modern age while contributing to sustainability and safety in engineering practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories