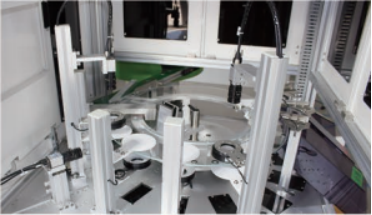

rotary shaft seal manufacturers

Understanding Rotary Shaft Seal Manufacturers

Rotary shaft seals are essential components in various machinery and equipment, playing a critical role in preventing leaks of fluids or lubricants around rotating shafts. These seals help maintain the necessary lubrication for the components, ensuring optimal performance, efficiency, and longevity. Due to their significance, rotary shaft seal manufacturers have become integral to many industries, including automotive, aerospace, industrial, and consumer goods.

The Importance of Rotary Shaft Seals

Rotary shaft seals are designed to perform in challenging environments, where exposure to contaminants, pressure fluctuations, and varying temperatures is common. They are typically made from a mix of rubber, silicone, and other materials that enhance their durability and compatibility with different fluids. Properly functioning rotary shaft seals prevent fluid leakage, which could lead to machinery failure, safety hazards, and increased operational costs. Therefore, selecting the right seal is critical for the reliability of machinery.

Types of Rotary Shaft Seals

There are several types of rotary shaft seals, and manufacturers often specialize in different varieties depending on the application. The most common types include

1. Lip Seals These seals have a flexible lip that makes contact with the shaft, providing a tight seal that prevents leakage. They are ideal for lower pressure applications and are commonly used in automotive and industrial applications.

2. U-Cup Seals Often employed in hydraulic systems, U-cup seals are designed to accommodate both dynamic and static sealing applications. Their shape allows for effective sealing even under high pressures.

3. V-Ring Seals These seals are unique in that they utilize a flexible ring that rotates with the shaft, providing a dynamic sealing function. V-ring seals are typically used in applications with moderate pressures and can accommodate shaft misalignment.

Characteristics of Quality Manufacturers

rotary shaft seal manufacturers

When it comes to selecting a manufacturer for rotary shaft seals, several key characteristics should be considered

1. Quality of Materials Premium manufacturers use high-quality materials that ensure durability and resistance to wear and tear. Materials should be compatible with the specific fluids they will encounter, avoiding degradation over time.

2. Customization Options Different applications may require specific sizes, designs, or materials. Manufacturers that offer customization can better meet the unique requirements of their clients.

3. Testing and Certifications Quality manufacturers often have rigorous testing protocols in place to ensure their products meet industry standards. Certifications such as ISO 9001 indicate a commitment to quality management in production processes.

4. Technical Support and Expertise A knowledgeable manufacturer offers more than just products; they provide technical support to help clients choose the right seals for specific applications. This expertise can be invaluable in complex situations.

5. Reputation and Experience Companies with a long-standing reputation in the industry tend to produce reliable products. Researching customer feedback and past projects can provide insight into a manufacturer’s consistency and reliability.

The Future of Rotary Shaft Seal Manufacturing

As industries evolve, the demand for more advanced rotary shaft seals continues to grow. Manufacturers are increasingly focusing on producing seals that can withstand extreme conditions, including higher temperatures, corrosive environments, and enhanced mechanical stress. Innovations in materials science, such as the development of elastomers with greater fatigue resistance, are paving the way for next-generation sealing solutions.

Furthermore, the push for sustainability has led manufacturers to explore eco-friendly materials and production methods. There is a growing trend towards developing seals that not only perform efficiently but also minimize environmental impact.

Conclusion

Rotary shaft seals are indispensable in ensuring the smooth operation of machinery across various sectors. Understanding the complexities of these seals and the manufacturers that produce them is crucial for businesses that rely on these components. By choosing quality manufacturers that prioritize material integrity, design versatility, and customer support, companies can safeguard their operations against the challenges of fluid leakage and machinery failure. In a rapidly advancing industrial landscape, the role of rotary shaft seal manufacturers will only grow more significant, driving innovations that ensure reliability and efficiency in modern equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories