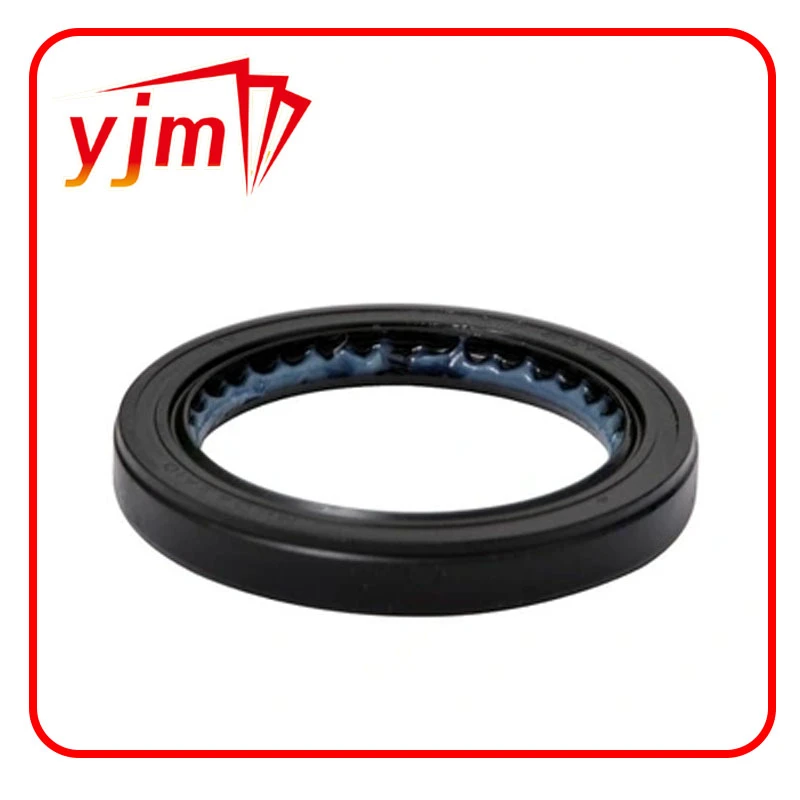

rotary shaft seal

The Importance of Rotary Shaft Seals in Mechanical Applications

Rotary shaft seals, often referred to as oil seals or lip seals, play a crucial role in machinery where rotating shafts are involved. These seals are designed to retain lubricant within a housing while preventing the ingress of contaminants such as dirt, dust, and water. A well-functioning rotary shaft seal contributes significantly to the reliability and longevity of mechanical systems in various industries, including automotive, aerospace, and manufacturing.

Understanding Rotary Shaft Seals

A rotary shaft seal typically consists of a flexible lip that comes into contact with the surface of a rotating shaft. This lip is usually made of rubber or elastomeric materials, which provide the necessary elasticity and flexibility to maintain a good seal under varying conditions. The design of the seal allows it to adapt to small surface irregularities on the shaft and compensate for any misalignment.

There are several types of rotary shaft seals, including single-lip seals, double-lip seals, and specialized designs like axially split seals, each suited for specific applications

. Single-lip seals are the most common and are used in applications where only one side needs sealing. In contrast, double-lip seals provide enhanced protection by offering a secondary barrier against contaminants.Key Functions of Rotary Shaft Seals

1. Lubrication Retention One of the primary functions of rotary shaft seals is to retain oil or grease used for lubrication within a bearing or housing. This is essential for the smooth operation of machinery, as proper lubrication reduces friction and wear between moving parts.

2. Contaminant Exclusion Rotary shaft seals prevent external contaminants from entering the lubricated areas. Dust, dirt, and moisture can cause significant damage to bearings and other moving parts if they penetrate the system. A good seal helps maintain the integrity of the lubricant and protects the machinery from premature failure.

3. Pressure Maintenance In applications where pressure is a concern, such as hydraulic systems, seals help maintain the necessary pressure levels. This function is essential for the efficient operation of hydraulic cylinders and other pressurized components.

rotary shaft seal

Installation and Maintenance Considerations

Proper installation of rotary shaft seals is critical for optimal performance. A poorly installed seal can lead to leaks and a quick loss of lubrication, resulting in increased wear and potential failure of the machinery. The shaft surface must be free from scratches, burrs, and other imperfections to ensure a good sealing surface.

Periodic maintenance checks are essential to ensure the integrity of the seals. Signs of seal failure may include lubricants leaking from the housing or visible damage to the seal itself. Replacing worn or damaged seals proactively can prevent further damage to the machinery and avoid costly downtime.

Advancements in Seal Technology

Over the years, advancements in materials and technology have led to the development of more durable and efficient rotary shaft seals. Modern materials, such as fluoropolymers and advanced elastomers, offer better resistance to temperature extremes, chemical exposure, and wear. These improvements have extended the lifespan of seals and enhanced their performance in challenging environments.

Moreover, the incorporation of smart technologies, such as sensors within the seals, can provide real-time monitoring of seal performance and early warning signs of potential failures. This proactive approach allows for timely maintenance and can significantly reduce operational disruptions.

Conclusion

Rotary shaft seals are integral components in many mechanical systems, providing essential functions that protect machinery and ensure efficient operation. As industries continue to evolve, the importance of reliable sealing solutions remains paramount. Investing in quality seals and maintaining them properly will enhance the reliability and efficiency of any rotating machinery, ultimately leading to improved productivity and reduced costs in operations. Understanding their significance is vital for engineers and maintenance professionals tasked with the upkeep of complex mechanical systems.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories