rotary shaft seals

Understanding Rotary Shaft Seals Essential Components for Mechanical Efficiency

Rotary shaft seals, often referred to as oil seals or rotary seals, play a crucial role in various mechanical systems. These seals are primarily designed to prevent the leakage of fluids while keeping contaminants at bay, ensuring optimal performance of rotating shafts in machinery. Their applications span numerous industries, from automotive to aerospace, and industrial machinery to consumer products.

The primary function of a rotary shaft seal is to enclose the space around a rotating shaft, thereby preventing lubricants such as oil or grease from escaping while simultaneously blocking dirt, dust, and other harmful particles from entering the system. This is vital for maintaining the integrity and longevity of machinery, as any leakage can lead to reduced efficiency, increased wear, and higher operational costs.

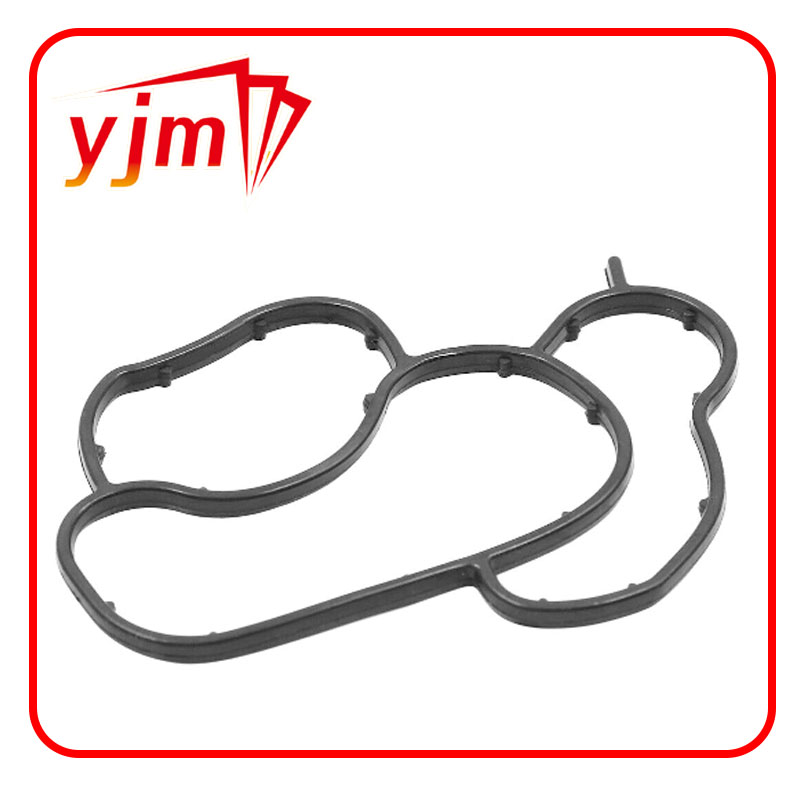

Rotary shaft seals consist of several key components, including a flexible sealing lip, a casing, and in many cases, a spring that helps maintain contact between the lip and the shaft. The sealing lip is often made from elastomers like nitrile, fluoroelastomer, or silicone, chosen for their durability and resistance to temperature fluctuations and chemical exposure. The design of the seal must align with the shaft's diameter and the application's unique requirements, including pressure conditions and environmental factors.

rotary shaft seals

The effectiveness of a rotary shaft seal depends on several factors, including the material used, design configurations, and installation practices. A well-designed seal significantly reduces friction and wear on the shaft while maintaining a tight seal under various operational stresses. Proper installation is also critical; an incorrectly installed seal can lead to premature failure, resulting in costly repairs and downtime.

In recent years, advancements in materials and manufacturing processes have improved the performance of rotary shaft seals

. Innovations such as enhanced lip designs, better materials for extreme conditions, and advanced sealing technologies are being integrated to meet the needs of modern applications.In conclusion, rotary shaft seals are vital components that ensure the efficiency and reliability of rotating machinery. By preventing fluid leakage and warding off contaminants, they play an essential role in extending the life of equipment and maintaining optimal operational performance. In a world where machinery reliability is paramount, understanding and investing in quality rotary shaft seals is crucial for any industry.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories