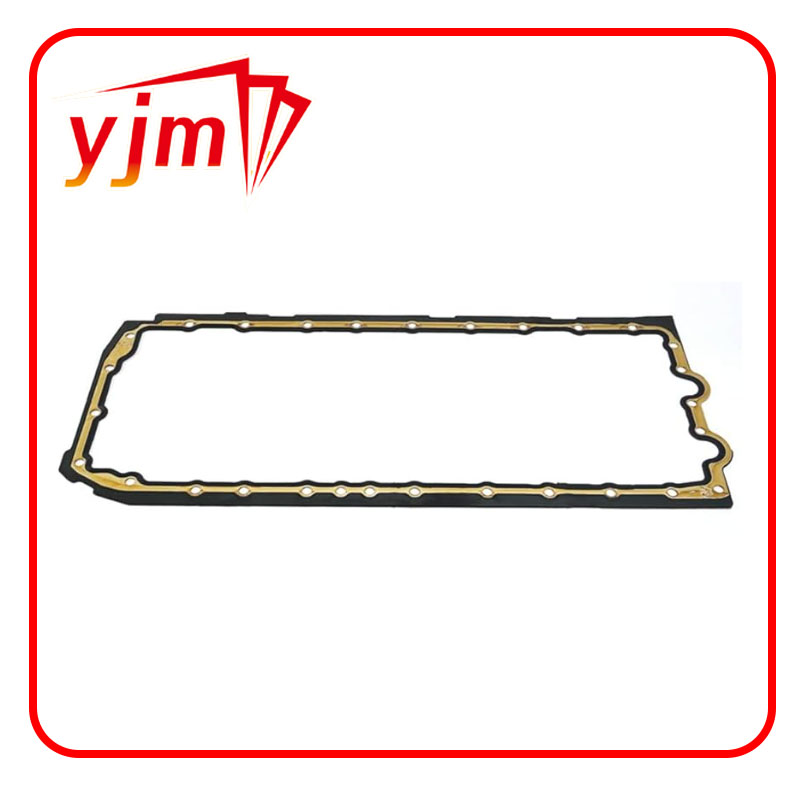

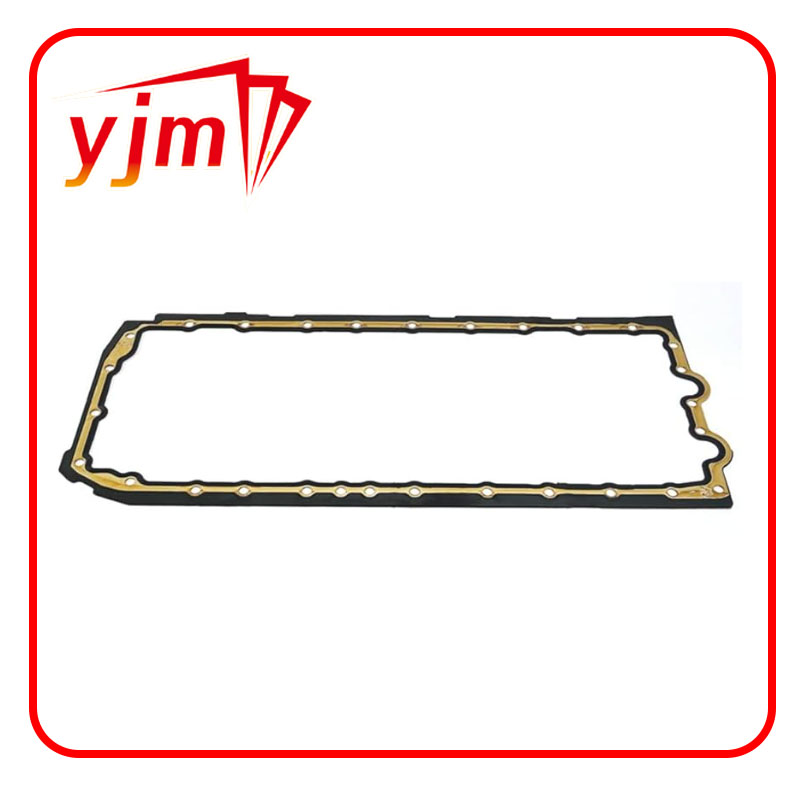

Rondelle bonded seals provide excellent protection.

The benefits of this technology are multifaceted

The benefits of this technology are multifaceted

The benefits of this technology are multifaceted

The benefits of this technology are multifaceted rondelle bonded seal. Firstly, the pre-assembled nature of the rondelle bonded seal streamlines the installation process, saving technicians time and reducing the margin for human error. Furthermore, the robust adhesion between the gasket and the metal ring enhances resistance to vibration and mechanical shocks, which are common challenges in industrial settings.

Perhaps most importantly, the rondelle bonded seal improves reliability. By eliminating potential points of failure associated with traditional seals, it ensures consistent performance over extended periods. In applications where downtime can be costly—such as in manufacturing or aerospace sectors—this reliability translates directly into economic benefits.

In conclusion, the rondelle bonded seal represents a pinnacle of engineering sophistication. Its creation involves meticulous attention to material selection, precision craftsmanship, and advanced adhesive technology. The result is a component that not only safeguards against leaks but also optimizes operational efficiency and reduces maintenance requirements. For those who appreciate the harmony of form and function, the rondelle bonded seal is indeed a marvel to behold.

rondelle bonded seal. Firstly, the pre-assembled nature of the rondelle bonded seal streamlines the installation process, saving technicians time and reducing the margin for human error. Furthermore, the robust adhesion between the gasket and the metal ring enhances resistance to vibration and mechanical shocks, which are common challenges in industrial settings.

Perhaps most importantly, the rondelle bonded seal improves reliability. By eliminating potential points of failure associated with traditional seals, it ensures consistent performance over extended periods. In applications where downtime can be costly—such as in manufacturing or aerospace sectors—this reliability translates directly into economic benefits.

In conclusion, the rondelle bonded seal represents a pinnacle of engineering sophistication. Its creation involves meticulous attention to material selection, precision craftsmanship, and advanced adhesive technology. The result is a component that not only safeguards against leaks but also optimizes operational efficiency and reduces maintenance requirements. For those who appreciate the harmony of form and function, the rondelle bonded seal is indeed a marvel to behold. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories