Innovative Approaches to Reusing Crush Washers for Enhanced Sustainability and Cost Efficiency

The Benefits and Methods of Reusing Crush Washers

In various mechanical and automotive applications, crush washers play a crucial role in sealing connections and preventing fluid leaks. While they are often seen as single-use components, there is a growing awareness of the environmental and economic benefits associated with reusing crush washers. This article explores the advantages of reusing these washers and provides practical methods for doing so effectively.

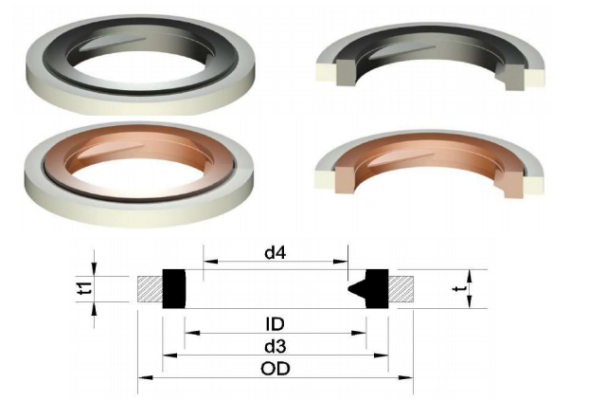

Understanding Crush Washers

Crush washers, typically made of materials like aluminum, copper, or rubber, are designed to deform under pressure. When compressed between two mating surfaces, they fill irregularities and create a tight seal. This property makes them particularly useful in applications such as hydraulic systems, oil filters, and fuel lines. However, after a single use, many assume that crush washers must be discarded, leading to unnecessary waste.

Environmental Benefits

One of the primary advantages of reusing crush washers is the significant reduction in waste. Discarding washers after each use contributes to environmental pollution and increases landfill volume. By reusing these components, individuals and businesses can minimize their ecological footprint. This practice also aligns with the principles of sustainability and responsible resource management, encouraging a circular economy where items are used to their full potential before being disposed of.

Economic Advantages

From an economic standpoint, reusing crush washers can lead to considerable cost savings. Over time, the expenses associated with purchasing new washers can accumulate, particularly for businesses with high-volume requirements. By implementing a reuse strategy, companies can reduce their operational costs, allowing them to allocate resources to other vital areas. Additionally, for automotive enthusiasts and DIY mechanics, reusing crush washers can save money on repairs and maintenance.

Methods for Reusing Crush Washers

reusing crush washer

While reusing crush washers is beneficial, it is essential to do so with care to ensure effective sealing and safety. Here are some practical methods for successfully reusing crush washers

1. Inspection Before reusing a crush washer, inspect it for signs of wear, deformation, or damage. If the washer shows significant wear or has cracks, it’s best to replace it to maintain a proper seal.

2. Cleaning Many washers can be cleaned and reused. Use a solvent or degreaser to remove any oil, grease, or debris. This ensures that the washer will form a consistent and effective seal upon reinstallation.

3. Proper Compression When reinstalling a crush washer, ensure that it is compressed evenly. Over-tightening can lead to premature failure, while insufficient tightening might result in leaks. Following manufacturer specifications for torque settings is crucial.

4. Heat Cycles Be aware that crush washers can lose their sealing properties after multiple heat cycles. In high-temperature applications, consider the number of times a washer has been reused and monitor for leaks.

5. Documentation For businesses, maintaining a record of used crush washers can help track their integrity and performance. This documentation can inform decision-making about when to retire a washer from service.

Conclusion

Reusing crush washers presents significant environmental and economic benefits. As industries move toward more sustainable practices, adopting the reuse of these simple yet vital components is a step forward. By employing careful inspection, cleaning, and proper installation techniques, both individuals and businesses can extend the life of crush washers while contributing to a more sustainable future. Embracing this practice not only saves money but also supports a healthier planet, making it a wise choice for all.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories