Ways to Repurpose Crush Washers for Sustainable Use in Various Applications

The Importance of Reusing Crush Washers A Sustainable Approach

In an era where sustainability is more important than ever, industries and individuals alike are becoming increasingly aware of the need to reduce waste and optimize resources. One small yet significant way to contribute to this effort is by reusing crush washers. While they may seem like insignificant components in mechanical assemblies, understanding their function and exploring the potential for reuse can lead to both economic and environmental benefits.

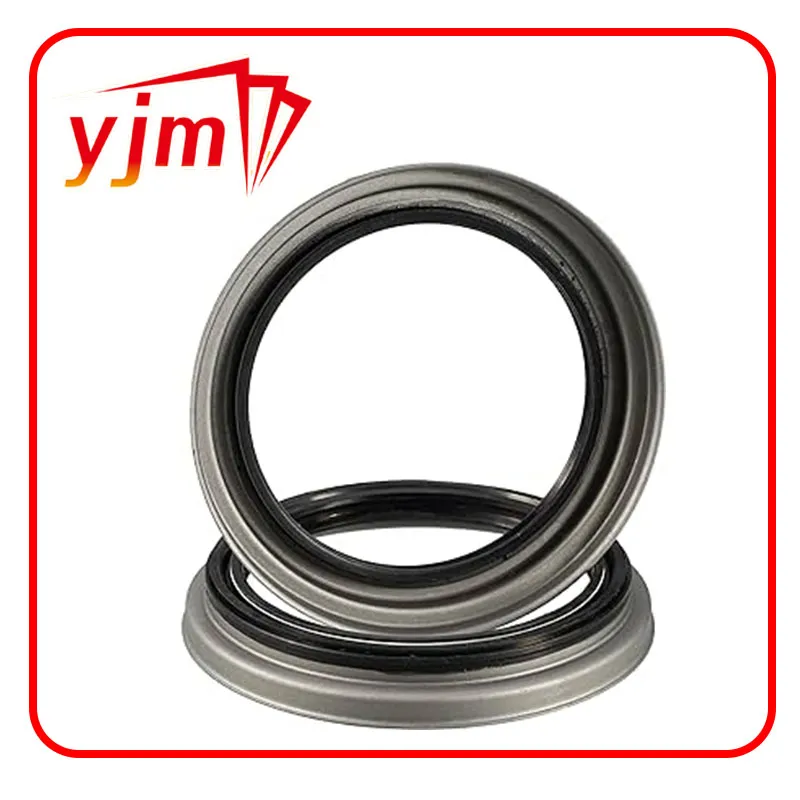

What Are Crush Washers?

Crush washers, also known as sealing washers, are used in various applications to create a tight seal between two surfaces. They are typically made from soft materials such as aluminum, copper, or rubber, which allow them to deform and fill any gaps between the surfaces when compressed. This property is crucial in preventing leakage in hydraulic, pneumatic, and automotive applications, where maintaining pressure and preventing contamination is essential.

The Case for Reusing Crush Washers

Traditionally, crush washers are designed for single-use applications. Once installed and compressed, they take on a deformed shape that is specific to the surfaces they seal. However, there are instances where they can be effectively reused, particularly in non-critical applications or where identical conditions are maintained. Here are several reasons to consider reusing crush washers

1. Cost Savings Reusing crush washers can lead to significant savings on materials, especially for businesses that frequently engage in assembly and disassembly tasks. By inspecting and reusing these components, businesses can lower their operational costs, which is especially valuable in competitive markets.

2. Waste Reduction In a world grappling with mounting waste, every effort to reduce material consumption counts. By reusing crush washers, individuals and companies can contribute to decreasing environmental impact. This aligns with global objectives aimed at promoting sustainability and responsible consumption.

reusing crush washer

3. Resource Optimization The manufacturing of crush washers requires raw materials, energy, and labor. Reusing them prolongs their lifecycle and minimizes the demand for new products. This not only lessens the strain on natural resources but also reduces the carbon footprint associated with production and transportation.

Best Practices for Reusing Crush Washers

To effectively incorporate crush washer reuse into your practices, consider the following best practices

- Inspection Before reusing a crush washer, it is essential to inspect it for damage. Look for cracks, excessive deformation, or wear that could compromise its sealing ability. If it still maintains its integrity, it can be reused effectively.

- Cleanliness Ensure that crush washers are clean and free from contaminants. This is particularly important in applications involving fluids or gases, as residues can lead to failure in sealing.

- Context of Use Evaluate the application context. In less critical systems, or when reusing in similar conditions as the original installation, crush washers can often perform satisfactorily. However, avoid reusing them in high-pressure environments or where safety is a concern.

Conclusion

Reusing crush washers may appear to be a small step, but it carries significant implications for cost savings and environmental benefit. As the world shifts towards more sustainable practices, it is imperative that both individuals and businesses start adopting such measures. In doing so, we can collectively contribute to a more sustainable future, one small component at a time. The journey towards sustainability involves many facets, and reusing components like crush washers is a perfect example of how small changes can lead to substantial impact. Let us embrace the potential of reuse in our daily practices and advocate for a culture of sustainability in every aspect of our lives.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories