reusing crush washer

Reusing Crush Washers A Sustainable Approach to Maintenance

In today's world, where sustainability and environmental awareness are increasingly important, the concept of reusing components in automotive and engineering maintenance has gained significant traction. One such component that merits attention is the crush washer. Often overlooked, these small, yet vital, components play a crucial role in ensuring leak-free connections in various mechanical systems. By understanding the functions of crush washers and exploring the possibilities of reusing them, we can contribute to a more sustainable future in maintenance practices.

What is a Crush Washer?

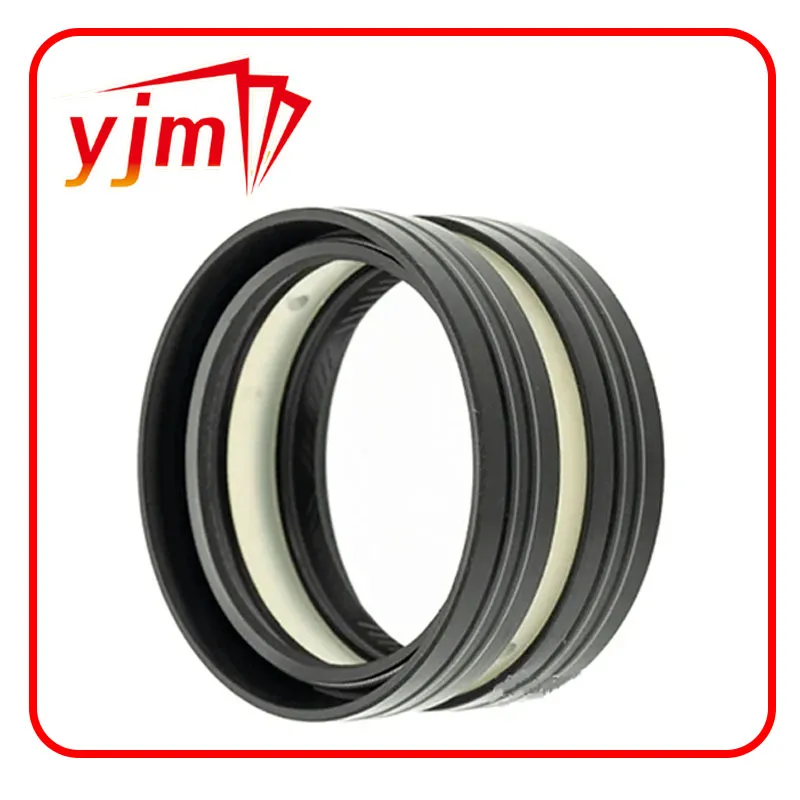

A crush washer, also known as a sealing washer or compression washer, is typically made from materials like copper, aluminum, or rubber. They are designed to create a tight seal between two mating surfaces when compressed. Once installed, the washer flattens under the pressure of the bolt or screw, ensuring that fluids or gases do not leak. This makes them essential in applications such as automotive oil lines, hydraulic systems, and plumbing, where maintaining a leak-proof seal is critical.

The Benefits of Reusing Crush Washers

1. Cost Savings One of the most immediate benefits of reusing crush washers is the potential for cost savings. Instead of purchasing new washers for every maintenance task, mechanics and technicians can often reuse existing ones. This can significantly lower operational costs, particularly in industries that rely heavily on frequent maintenance.

2. Environmental Impact Reusing components like crush washers contributes to reducing waste and minimizing environmental impact. The manufacturing process of new washers requires energy and raw materials, which contribute to carbon emissions and resource depletion. By reusing already manufactured washers, we can lessen the demand for these resources and help preserve the environment.

3. Resource Efficiency In the context of a circular economy, reusing components promotes resource efficiency. By extending the life of existing crush washers, industries can reduce the overall demand for new products, thereby conserving materials and promoting sustainability.

reusing crush washer

Best Practices for Reusing Crush Washers

While the benefits of reusing crush washers are clear, it is crucial to follow best practices to ensure that safety and effectiveness are not compromised

- Inspection Before reusing a crush washer, inspect it carefully for any signs of wear or damage. Look for cracks, deformities, or excessive flattening. If the washer shows significant wear, it is advisable to replace it with a new one to maintain the integrity of the seal.

- Material Considerations Different material types have different properties. Copper washers can be reused multiple times due to their malleable nature, whereas rubber washers may degrade over time. Understanding the material properties will help determine the feasibility of reuse.

- Proper Storage To maximize the lifespan of reusable crush washers, store them in a clean, dry environment. Avoid exposure to harsh chemicals or extreme temperatures, which can degrade their materials and reduce their effectiveness.

Conclusion

The practice of reusing crush washers not only offers tangible benefits in terms of cost and environmental impact but also underscores a shift toward more sustainable maintenance practices. As industries continue to evolve, embracing such methods can lead to significant advancements in resource management and efficiency. By being mindful of our choices and recognizing the value in components often deemed expendable, we can foster a culture of sustainability within the maintenance landscape.

Whether you are a DIY enthusiast or a professional technician, considering the reuse of crush washers is a practical step toward environmental stewardship and economic efficiency. It’s time we appreciate the small components that contribute significantly to the durability and reliability of our systems, making sustainability an integral part of our maintenance routines.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories