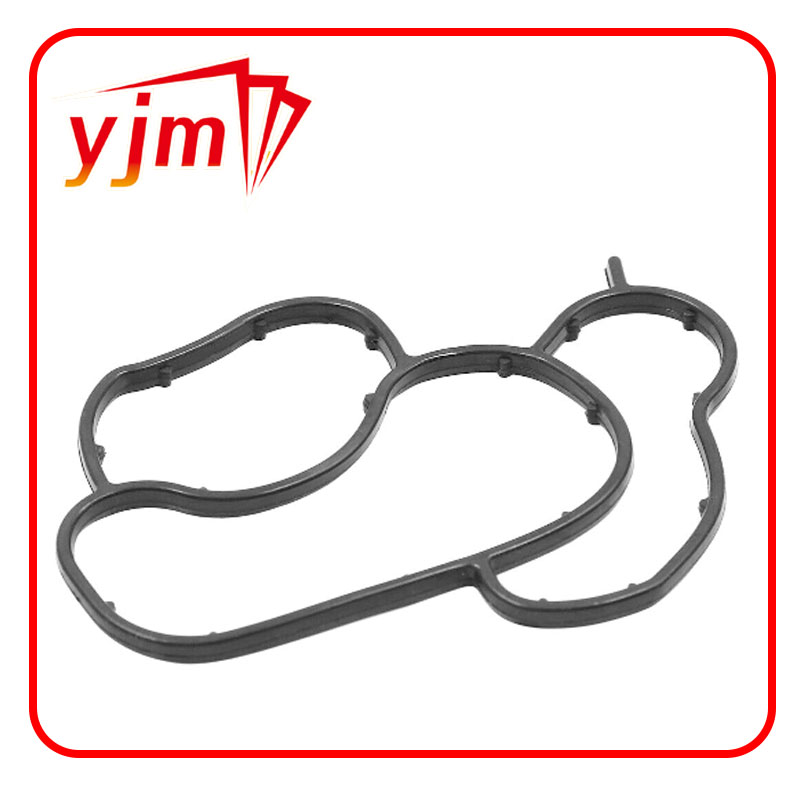

retainer oil seal

Understanding Retainer Oil Seals The Unsung Heroes of Machinery

In the world of machinery and automotive engineering, components such as engines, transmissions, and differentials rely on a variety of seals to operate efficiently and reliably. One of the most crucial seals in this domain is the retainer oil seal, often overlooked but vital for the longevity and performance of mechanical systems.

What is a Retainer Oil Seal?

A retainer oil seal is a mechanical component designed to retain lubricants, such as oil or grease, while preventing contamination from external elements, such as dirt and moisture. These seals are typically made from elastomeric materials like rubber or synthetic compounds that provide flexibility and durability. The primary function of a retainer oil seal is to maintain the internal lubrication of machinery, which is essential for reducing friction and wear between moving parts.

The Design and Functionality of Retainer Oil Seals

Retainer oil seals come in various designs tailored to their specific applications. They typically consist of a seal body, a sealing lip, and a supporting retainer or metal casing. The sealing lip is the most critical part of the seal; it makes contact with a rotating shaft and forms a barrier that prevents lubricant leakage. The retainer provides structural support and ensures that the seal maintains its shape under pressure and temperature fluctuations.

The functionality of a retainer oil seal hinges on its ability to create a hydraulic seal

. The sealing lip's design allows it to compress against the shaft, forming a tight barrier that prevents oil from escaping the housing or gear case. At the same time, it enables the shaft to rotate without significant resistance, ensuring smooth operation.Importance of Retainer Oil Seals

retainer oil seal

The importance of retainer oil seals cannot be overstated. They play a pivotal role in the efficiency and reliability of machinery. Without these seals, lubricants would leak out, leading to increased friction, overheating, and potential mechanical failure. Furthermore, when contaminants enter the machinery, they can cause significant damage to internal components, leading to costly repairs and extended downtime.

Maintaining a proper seal contributes to the longevity of machinery. Regular inspection and replacement of worn or damaged retainer oil seals can prevent catastrophic failures and enhance performance. In automotive applications, for example, a functioning retainer oil seal can mean the difference between a well-running engine and one plagued by oil leaks and overheating issues.

Trends and Innovations

The industry is witnessing innovations in the design and materials used for retainer oil seals. Advances in technology are leading to the development of seals that withstand higher temperatures, pressures, and aggressive chemicals. These advancements enhance their durability and expand their applications across various industries, including automotive, aerospace, and manufacturing.

Additionally, proper sealing techniques, improved manufacturing processes, and better quality control measures are ensuring that these seals perform reliably over their intended lifespan. The focus on sustainability is also sparking interest in developing eco-friendly materials for oil seals, reducing the environmental impact of industrial processes.

Conclusion

Retainer oil seals are integral components that significantly contribute to the smooth operation of machinery. Their role in retaining lubricants while keeping contaminants at bay is essential for optimal performance and longevity. As industries evolve and technology advances, the importance of these unsung heroes of mechanical engineering will only grow, ensuring that machines continue to operate efficiently and effectively for years to come.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories