Rebuild Kit for Enhanced Performance and Longevity in Your Equipment

Rebuild Kits Revitalizing Your Equipment for Optimal Performance

In the world of machinery and equipment maintenance, rebuild kits play a pivotal role in ensuring longevity and efficiency. Whether you're working with automotive engines, outdoor power equipment, or industrial machinery, a rebuild kit can be the key to revitalizing your gear without the cost of a complete replacement. In this article, we will explore what rebuild kits are, their benefits, and how to effectively utilize them to enhance the performance of your equipment.

What is a Rebuild Kit?

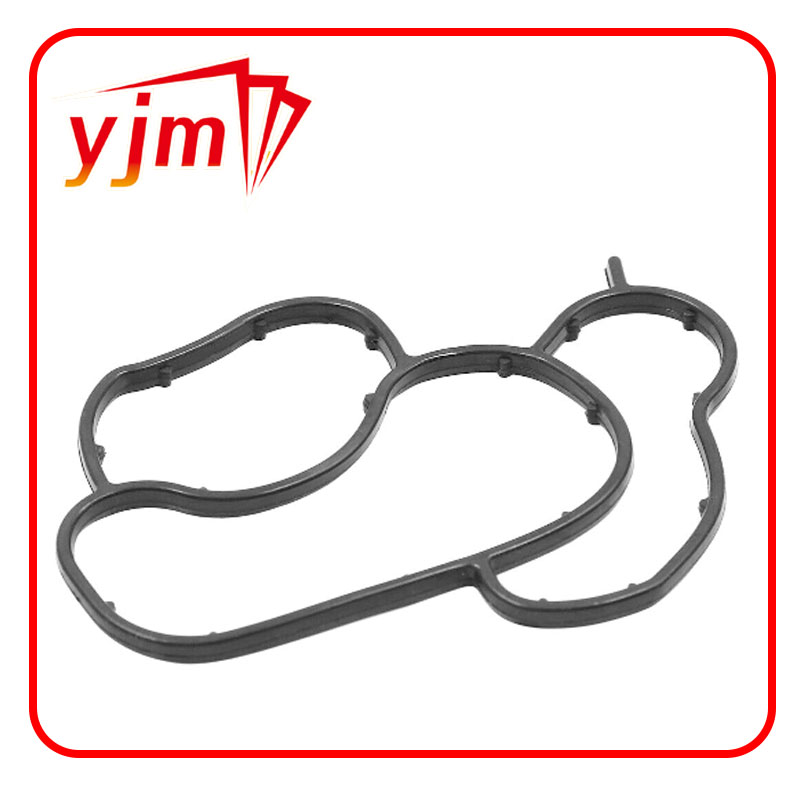

A rebuild kit is a collection of components designed to restore an engine or mechanical assembly back to its original operating condition. These kits typically include gaskets, seals, bearings, and sometimes even pistons, rings, and other engine internals. They are tailored to specific models and often offer a cost-effective solution for maintenance and repair compared to purchasing new parts individually.

Advantages of Using Rebuild Kits

1. Cost-Effectiveness One of the primary benefits of a rebuild kit is the significant savings it offers. Instead of buying individual parts, which can quickly add up, rebuilding with a kit provides a complete solution at a fraction of the cost.

2. Convenience Rebuild kits come with all the necessary components, making it easier for technicians and DIY enthusiasts to tackle repairs. Instead of spending time sourcing parts, everything needed is contained within the kit.

3. Quality Assurance Many manufacturers produce rebuild kits using high-quality materials that meet or exceed original equipment specifications. This means that when users opt for a rebuild kit, they're often investing in parts that will provide reliable performance.

4. Performance Restoration Over time, wear and tear can significantly affect the performance of equipment. By utilizing a rebuild kit, users can restore their machinery to peak performance levels, enhancing efficiency and productivity.

5. Sustainability Repairing rather than replacing reduces waste and is often more environmentally friendly. Rebuild kits allow for the continued use of existing machinery, extending its lifespan and reducing the need for new resources.

How to Choose the Right Rebuild Kit

When selecting a rebuild kit, consider the following factors

rebuild kit for

1. Compatibility Ensure that the kit is specifically designed for your equipment model. Check for compatibility with the make, model, and year of your machinery.

2. Quality of Components Research the materials used in the kit. Look for kits that specify OEM (Original Equipment Manufacturer) components or those with proven performance reviews.

3. Complete Kits vs. Partial Kits Decide whether you need a complete rebuild kit or a partial one. Some kits focus on specific components, while others cover a full range of necessary parts.

4. Documentation and Support Opt for kits that come with detailed installation instructions and customer support options. This can make the installation process smoother and easier, especially for those less experienced.

Installation Tips

1. Prepare Your Workspace Before starting, ensure you have a clean, organized workspace with all the necessary tools.

2. Follow Manufacturer Instructions Adhere strictly to the provided instructions to prevent mistakes and ensure proper assembly.

3. Take Your Time Rushing through the installation can lead to errors. Take your time to ensure everything is installed correctly.

4. Check for Additional Issues While replacing components, look for other potential problems that may need attention.

Conclusion

Rebuild kits offer an excellent solution for those looking to maintain and enhance the performance of their machinery without breaking the bank. By understanding the components of a rebuild kit and how to select the right one for your needs, you can ensure that your equipment remains in top condition, ultimately leading to increased efficiency and productivity. Whether you're a professional technician or a weekend DIYer, embracing the power of rebuild kits can transform the way you approach maintenance and repair.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories