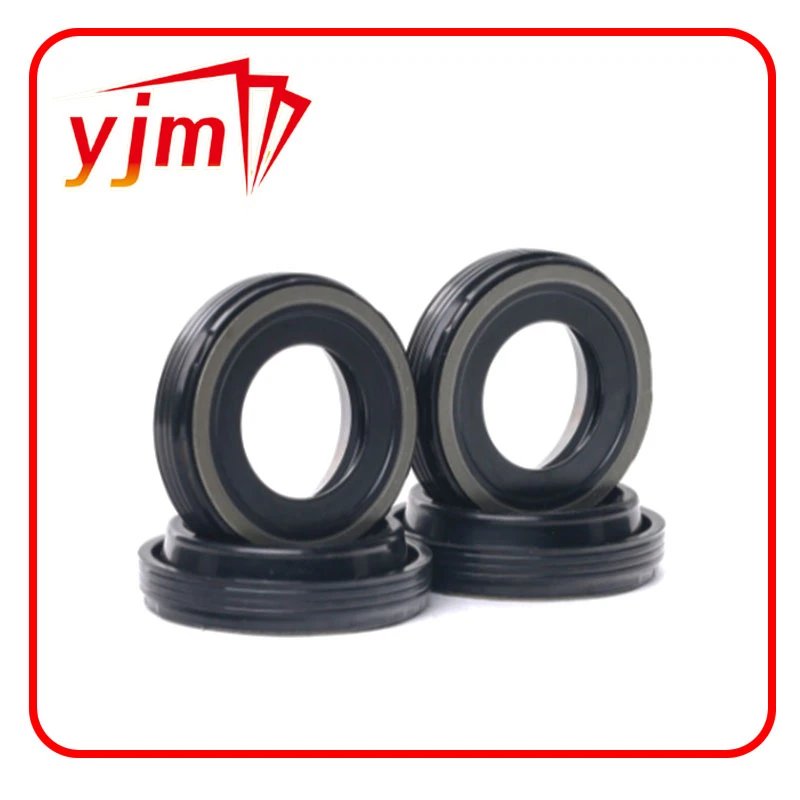

rear engine oil seal

Furthermore, the trustworthiness of a seal manufacturer is pivotal when selecting a replacement. Quality brands are known for rigorous testing and adherence to automotive standards, ensuring reliability and longevity. Automotive forums and reviews highlight consumer experiences that can guide purchasing decisions. Generally, reputable brands provide warranties that cover part failure, ensuring peace of mind for users. In terms of maintenance, it is beneficial for vehicle owners to maintain appropriate oil levels and change oil regularly. Clean oil reduces the chance of contaminants causing wear on the seal, prolonging its life. Moreover, using oil additives can soften and swell seals, potentially serving as a temporary measure to slow leaks before professional repair. Ultimately, understanding and prioritizing the rear engine oil seal can prevent costly repairs and maintain vehicle performance. Engaging with experienced mechanics, opting for high-quality materials, and adhering to recommended maintenance schedules all contribute significantly to preserving the integrity of this essential engine component. When taken seriously, car owners can ensure their vehicles continue to run efficiently and safely, embodying true automotive expertise and enhancing trust in their vehicular maintenance practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories