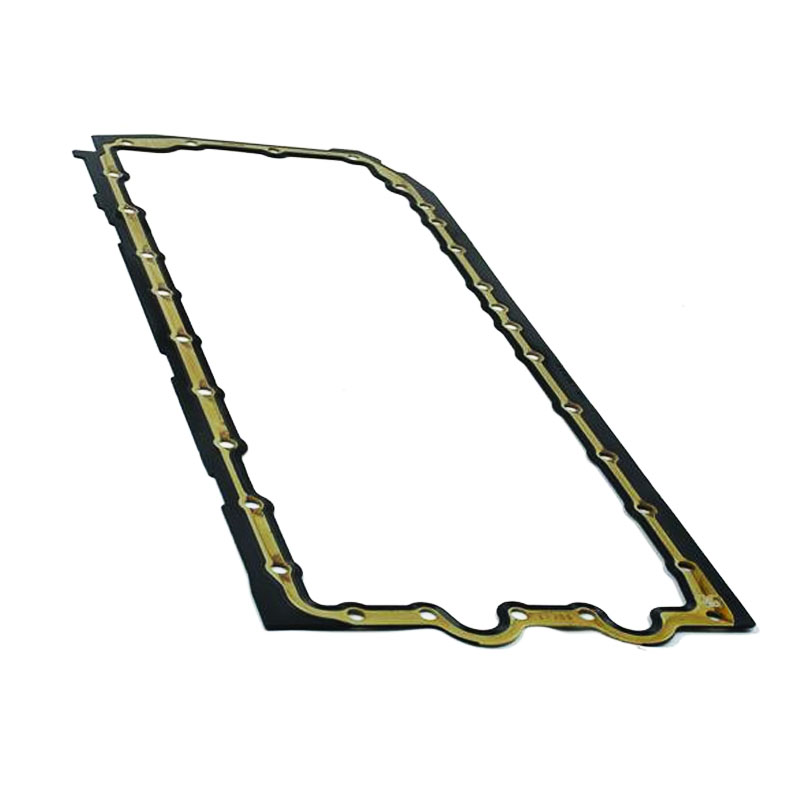

radial shaft seal ring

Understanding the Radial Shaft Seal Ring A Critical Component in Rotational Systems

The radial shaft seal ring plays a crucial role in a variety of mechanical systems, particularly those involving rotating shafts. As an essential component for preventing fluid leakage and protecting internal mechanisms from contaminants, these seals are integral in maintaining the efficiency and longevity of machinery.

What is a Radial Shaft Seal Ring?

A radial shaft seal ring, commonly referred to simply as a radial seal, is designed to maintain the integrity of a system where a rotating shaft passes through a stationary housing. Typically made from elastomeric materials, such as rubber or synthetic compounds, these seals feature a circular cross-section and are engineered to create a tight fit against the shaft surface as well as the housing. They essentially form a barrier that prevents the escape of lubricants, oils, or fluids, while also blocking the entry of dust, dirt, and other contaminants.

Working Principle

The operation of a radial shaft seal ring is based on the principles of friction and pressure. When the shaft rotates, the inner lip of the seal exerts a considerable amount of pressure against the shaft, creating a tight seal due to friction. This relationship is crucial because it helps to minimize wear from contamination and maintains the desired lubrication levels within the system.

Moreover, radial seals are designed to accommodate slight variations in shaft alignment and movement. They can function effectively even as the shaft experiences axial or radial play. This flexibility is essential in applications where some degree of movement is unavoidable, including automotive engines, pumps, and industrial machinery.

Applications

radial shaft seal ring

Radial shaft seal rings are ubiquitous in various industries. In automotive applications, they are commonly found in gearboxes, engine oil pumps, and differential assemblies. Here, they prevent oil leaks that can lead to reduced efficiency and increased wear on moving parts. In industrial contexts, radial seals are used in hydraulic systems, compressors, and turbines, providing essential protection against leakage.

Even in household appliances, such as washing machines and dishwashers, radial shaft seals can be found safeguarding against leaks that could cause damage or performance issues. Their versatility allows them to perform in numerous environments, including high-pressure, high-temperature, and corrosive settings.

Choosing the Right Seal

Selecting the appropriate radial shaft seal ring involves considering several factors. The type of fluid being sealed, temperature ranges, the rotational speed of the shaft, and the environmental conditions all play significant roles in determining the ideal material and design for the seal.

Elastomers like nitrile rubber (NBR), fluorocarbon (FKM), and silicone (VMQ) are often selected based on their resistance to fluid types and temperature extremes. For example, NBR is commonly used for oil seals due to its good oil resistance, while FKM is preferred for high-temperature and chemical resistance applications.

Maintenance and Replacement

Regular inspection and timely replacement are vital in ensuring that radial shaft seal rings function optimally. Signs of wear may include fluid leakage, increased noise, or noticeable wear patterns on the shaft. If these symptoms are observed, it is essential to address them promptly to avoid more extensive damage to the system.

In conclusion, the radial shaft seal ring is an indispensable component in a myriad of mechanical systems. Its ability to effectively seal and protect critical internal components from contamination and fluid loss plays a fundamental role in implementing efficient and reliable machinery. By understanding the importance of these seals, industries can optimize their maintenance practices, thereby enhancing performance and extending the lifespan of their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories