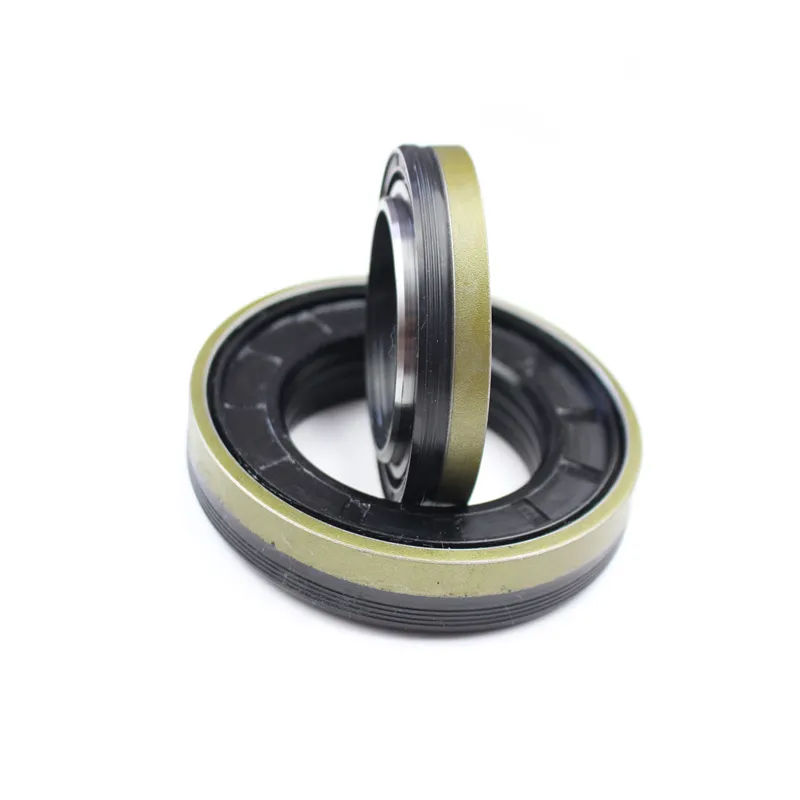

radial seal ring

Understanding Radial Seal Rings Importance and Applications

Radial seal rings are specialized components designed to create a secure and effective sealing mechanism between two mating surfaces, ensuring that fluids or gases do not leak during operation. They are used across various industries, including automotive, aerospace, and manufacturing, to prevent contamination and maintain system efficiency.

What is a Radial Seal Ring?

A radial seal ring functions by being compressed between components, typically during assembly. As pressure builds up from fluids or gases, the seal ring expands radially, pressing against the housing and the shaft, effectively closing the space that could permit leakage. This function is critical in systems where maintaining the integrity of the seal is paramount due to high pressure, temperature fluctuations, and exposure to various chemicals.

Radial seal rings come in various shapes and materials, which enables their application in different environments. Common materials include elastomers like nitrile, fluorocarbon, and silicone, as well as more robust materials such as metals or composites for demanding applications. The choice of material is vital, as it must withstand environmental conditions such as temperature extremes, chemical exposure, and wear.

Applications of Radial Seal Rings

1. Automotive Engineering In cars, radial seal rings are essential for various components, including engines, transmissions, and pumps. They help maintain oil and coolant seals while preventing leaks that could lead to performance issues and increased emissions.

2. Aerospace Industry The aerospace sector relies heavily on radial seal rings due to the extreme conditions encountered at high altitudes, including varying pressures and temperatures. These seals are crucial in maintaining cabin pressure and ensuring fuel systems operate efficiently.

3. Industrial Machinery In manufacturing equipment, radial seal rings are used to protect against fluid leakage in hydraulic systems and compressors. They ensure that operational efficiencies are maximized and equipment longevity is maintained.

radial seal ring

4. Consumer Products Everyday products like refrigerators and air conditioners also utilize radial seal rings to ensure that refrigerants do not leak, thus maintaining system efficiency and environmental compliance.

Design Considerations

When designing or selecting a radial seal ring, several factors should be considered

- Pressure and Temperature Ratings Knowing the maximum pressure and temperature limits the seal will face is crucial for selecting the right material and design. - Chemical Compatibility The seal must be compatible with the fluids it will encounter to avoid degradation and failure.

- Installation and Maintenance Proper installation is critical to ensure the effective performance of radial seal rings. Additionally, regular inspection and maintenance can prevent unexpected failures.

- Environment Factors such as operating speed, presence of abrasive particles, and overall system design will influence the choice of a radial seal ring.

Conclusion

Radial seal rings are indispensable components in many mechanical systems, playing a vital role in preventing leaks and maintaining operational integrity. Understanding their function, material properties, and application areas is essential for engineers and manufacturers alike. As industries continue to evolve and demand higher efficiency and reliability, the importance of radial seal rings will only continue to grow, driving innovations in material science and sealing technologies. Properly designed and implemented, these components ensure systems operate smoothly, ultimately leading to enhanced performance and sustainability in various applications.

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

-

Understanding Vital Engine Seals: Key Gaskets in Diesel and Performance Engines

News Jun.13,2025

-

The Vital Role of Bearings in Marine and Boating Applications

News Jun.13,2025

-

Sealing the System: A Complete Guide to Engine Oil Gaskets

News Jun.13,2025

-

Sealing the Foundation: A Complete Guide to Engine and Transmission Pan Gaskets

News Jun.13,2025

-

Essential Bearings and Hubs for Marine Vessels and Trailers

News Jun.13,2025

-

Your Complete Guide to Automotive Oil Drain Plugs and Valves

News Jun.12,2025

Products categories