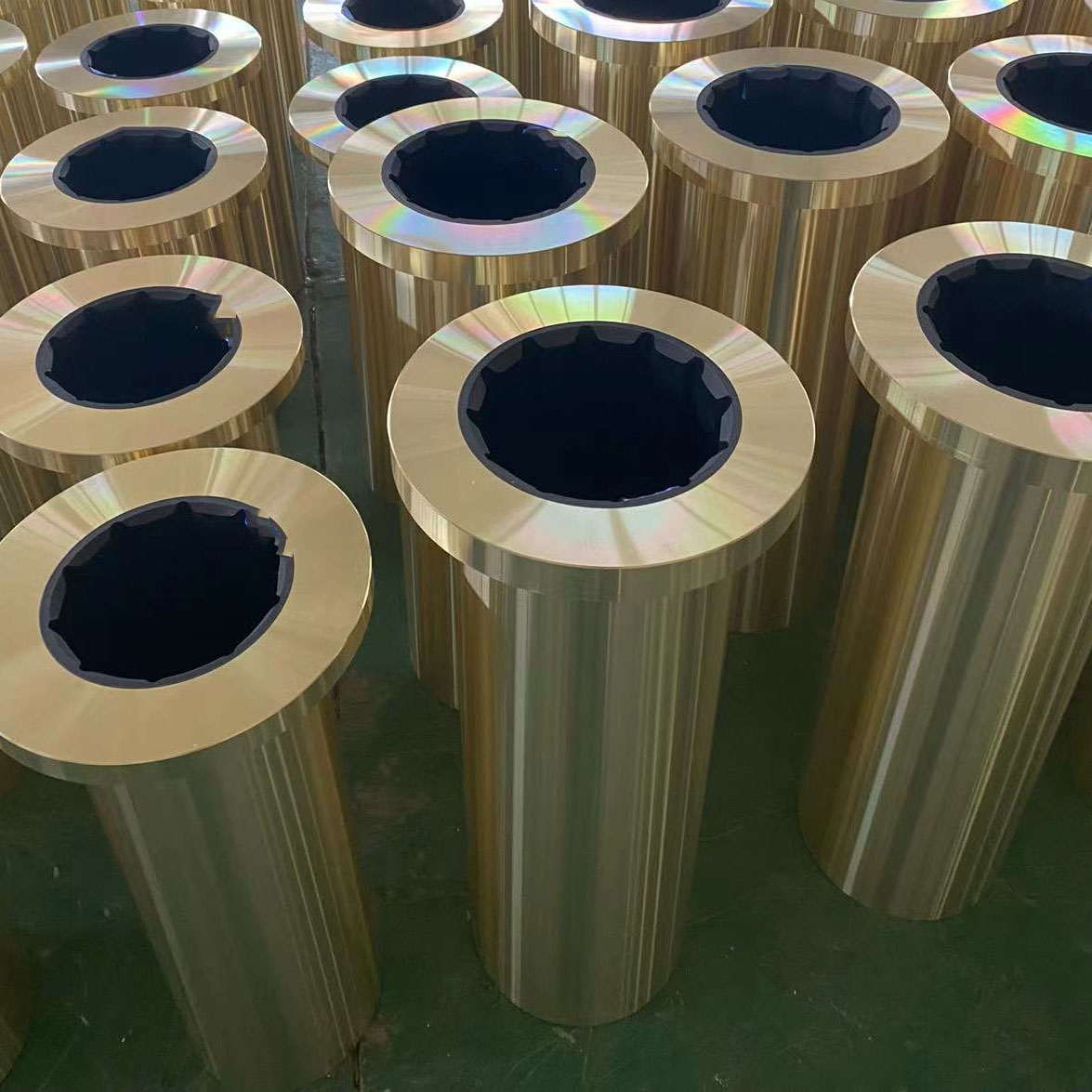

radial oil seals

Exploring Radial Oil Seals Importance and Applications

Radial oil seals, often referred to as radial lip seals, are critical components in various mechanical systems. These seals play a vital role in preventing the leakage of lubricants and protecting machined surfaces from contamination. Their significance extends across multiple industries, including automotive, aerospace, manufacturing, and power generation.

At its core, a radial oil seal consists of a circular elastomeric lip that makes contact with a rotating shaft, creating a barrier against fluids. The design of these seals is tailored to withstand pressure, temperature variations, and the presence of aggressive substances. The sealing lip is typically made from materials such as nitrile, fluorocarbon, or silicone, offering various benefits depending on the specific application.

In automotive applications, radial oil seals are extensively used in engines, transmissions, and differential units. They are crucial for ensuring that oil remains contained within these assemblies, preventing leaks that could lead to lubrication failure and severe mechanical damage. For instance, an engine’s oil seal helps maintain optimal oil levels while preventing contaminants from entering the lubrication system, thus prolonging the life of critical engine components.

radial oil seals

In industrial machinery, radial oil seals are often found in pumps, compressors, and gearboxes

. These seals are essential for maintaining efficiency and performance by ensuring a tight seal that keeps lubricants in and contaminants out. In heavy machinery, such as excavators and bulldozers, the durability of radial oil seals is paramount as they operate in harsh environments characterized by dust, dirt, and extreme temperatures.Moreover, radial oil seals are designed to accommodate axial and radial movements, making them versatile for various applications. Their installation can vary from just fitting them into a housing to employing additional retaining features to handle high-speed rotations and challenging operating conditions.

The manufacturing process of radial oil seals has evolved significantly, with advancements in material science enabling the development of seals that offer improved wear resistance, temperature tolerance, and lifespan. Technologies such as computer-aided design (CAD) and finite element analysis (FEA) are employed to enhance the seal's performance and reliability, ensuring that they meet the increasingly demanding requirements of modern machinery.

To conclude, radial oil seals are indispensable in numerous applications, providing a reliable means to enhance the performance and durability of mechanical systems. Their ability to prevent lubricant leaks and protect against contaminants underscores their importance in maintaining operational efficiency and extending the lifespan of machinery. As industries continue to innovate and evolve, the demand for high-quality radial oil seals will remain strong, ensuring these components will play a crucial role in various technological advancements.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories