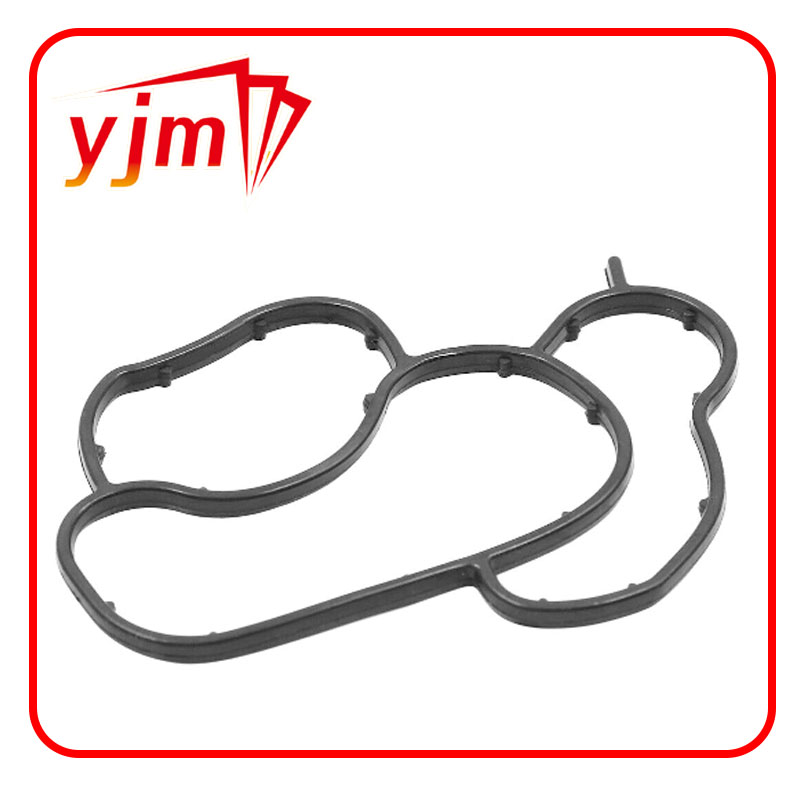

radial lip seal

Understanding Radial Lip Seals Importance and Applications

Radial lip seals are critical components used in various industries to prevent the leakage of fluids and to protect machinery from contaminants. These seals play a crucial role in ensuring the longevity and efficiency of mechanical systems by maintaining the integrity of lubricants and keeping out dirt, moisture, and other foreign particles.

A radial lip seal primarily consists of a flexible lip that is designed to create a tight seal around a rotating shaft. The seal's design allows it to adapt to slight misalignments and variations in shaft diameter, making it a versatile choice for different applications. The flexibility of the lip is crucial as it ensures a tight fit, which is essential for preventing leaks. The design also minimizes the friction between the rotating shaft and the seal, reducing wear and enhancing the overall performance of the machinery.

One of the key benefits of radial lip seals is their effectiveness in retaining lubricants within the system. This is particularly important in applications where machinery operates under high speeds and loads, as the loss of lubricant can lead to overheating and eventual failure. By keeping the lubricant contained, these seals not only extend the life of the machinery but also improve operational efficiency.

radial lip seal

Radial lip seals are widely used in a variety of industries, including automotive, aerospace, manufacturing, and agriculture. In the automotive sector, they are commonly found in engines, transmissions, and wheel hubs. Their ability to withstand high temperatures and pressures makes them ideal for these demanding applications. In aerospace, radial lip seals are used in hydraulic systems and engines, where reliability is paramount.

Furthermore, radial lip seals are often designed to meet specific requirements depending on the operational environment. This includes factors such as temperature, pressure, and the type of fluid being sealed. For instance, seals used in high-temperature applications may be made from specialized materials that can withstand extreme conditions without compromising their performance. Additionally, seals engineered for harsh environments, such as those found in agricultural machinery, may feature reinforced structures to enhance durability.

Another aspect of radial lip seals is their maintenance and replacement. Regular maintenance checks are essential to ensure their continued effectiveness. Inspecting seals for wear and tear can prevent unexpected breakdowns and costly repairs. When a seal is found to be worn out, it should be replaced promptly to avoid leaks that could result in damage to the machinery and environmental harm.

In conclusion, radial lip seals are indispensable components that significantly contribute to the efficiency and longevity of mechanical systems across various industries. Their ability to prevent fluid leakage and protect against contaminants is vital, making them a fundamental element in machine design and operation. As industries continue to evolve, the development of advanced materials and designs for radial lip seals will remain essential to meet the demands of increasingly complex applications. Understanding their function and importance can help engineers and maintenance personnel maximize the performance and lifespan of critical equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories