Understanding the Function and Importance of Rack and Pinion Seals in Mechanisms

Understanding Rack and Pinion Seals An Essential Component in Mechanical Systems

Rack and pinion systems are pivotal in various mechanical applications, transforming rotational motion into linear motion. This mechanism is prevalent in automotive steering, industrial machinery, and robotics, among other fields. While the efficiency of these systems is often attributed to their design and materials, the role of rack and pinion seals is equally critical. This article delves into the importance of these seals, their functionality, and best practices for maintenance.

At its core, the rack and pinion system consists of a circular pinion gear that engages with a linear rack. As the pinion turns, it pushes or pulls the rack in a straight line, thereby facilitating movement. However, this interaction involves significant friction and potential wear and tear, necessitating effective sealing solutions. Rack and pinion seals serve as barriers to contaminants and assist in retaining lubrication, ensuring smooth operation while minimizing wear.

One of the fundamental functions of rack and pinion seals is to prevent the ingress of dust, dirt, and other particles that can compromise the system. Contaminants can lead to increased friction, wear on the gear surfaces, and ultimately, system failure. Effective seals ensure that the lubricants remain within the system, providing necessary protection and increasing the lifespan of the rack and pinion assembly.

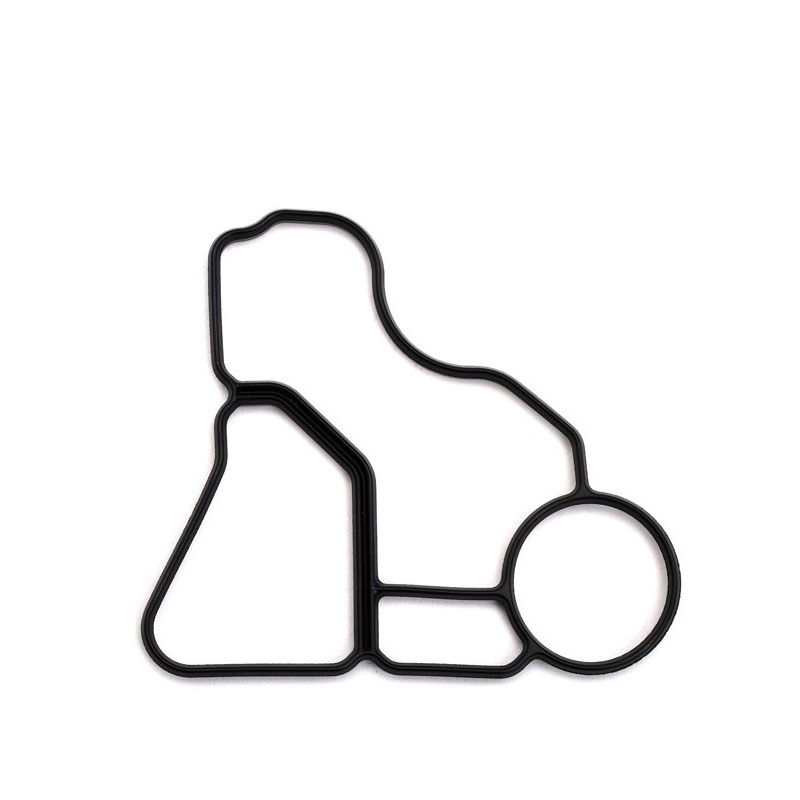

rack and pinion seals

In terms of materials, rack and pinion seals can be constructed from various substances, including rubber, polyurethane, and PTFE (Teflon). Each material offers unique advantages, such as high elasticity, chemical resistance, and durability under extreme conditions. Selecting the right seal material is crucial and is often dictated by the specific application environment and operational demands.

Maintenance of rack and pinion seals is vital for optimal performance. Regular inspection is essential to detect signs of wear or damage, which can include cracking, hardening, or deformation. Implementing a routine maintenance schedule that includes cleaning and reapplying lubricants can extend the life of the seals and, consequently, the entire rack and pinion system. Additionally, ensuring that the seals are correctly installed and free from misalignment is crucial to preventing premature failure.

The significance of rack and pinion seals extends beyond mere functionality; they contribute to the overall safety and reliability of mechanical systems. In automotive applications, well-maintained seals are essential for safe steering responses, while in industrial settings, they can prevent costly downtimes due to equipment failure.

In conclusion, rack and pinion seals may often go unnoticed, yet they play an indispensable role in the functionality and longevity of rack and pinion systems. By understanding their importance and implementing proper maintenance practices, industries can ensure optimal performance, reduce wear, and enhance the reliability of their mechanical systems. As technology advances, the evolution of rack and pinion seal design and materials will continue to play a critical role in the efficiency of future applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories