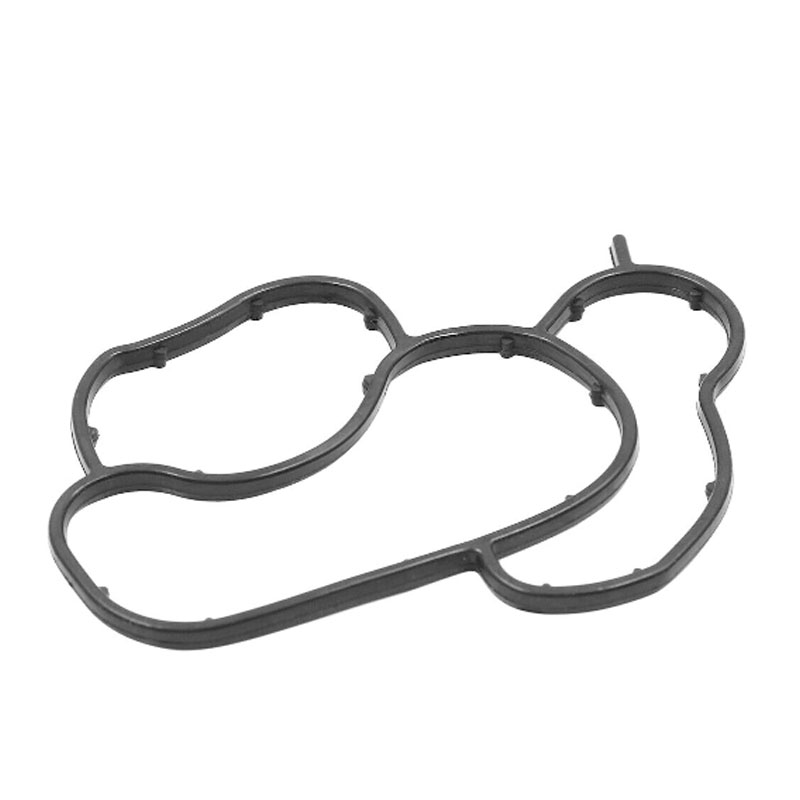

rack and pinion oil seal

Understanding Rack and Pinion Oil Seals

Rack and pinion systems are essential components in various mechanical systems, especially in steering mechanisms of vehicles. The rack, a linear gear, and the pinion, a circular gear, work in tandem to convert rotational motion into linear motion. While the functionality of these systems is crucial, one often overlooked component is the oil seal. This article delves into the significance of rack and pinion oil seals, their functionalities, materials, and maintenance practices.

Importance of Oil Seals

Oil seals, also known as shaft seals, play a vital role in the longevity and efficiency of rack and pinion systems. Their primary function is to prevent lubrication oil from leaking out of the gear housing and to keep contaminants, such as dust and dirt, from entering the system. Leaks can lead to inadequate lubrication, causing wear and tear on the gears, which can ultimately result in failure of the steering system. Proper sealing is crucial for maintaining optimal functioning and extending the lifespan of the rack and pinion assembly.

Materials Used for Oil Seals

Rack and pinion oil seals are typically made from various elastomers, including rubber, silicone, and polyurethane. Each material offers different advantages

1. Rubber Commonly used for its excellent sealing properties and resistance to wear. However, it may degrade over time when exposed to certain chemicals or extreme temperatures.

2. Silicone Known for its ability to withstand high temperatures, silicone seals are often used in applications where heat is a concern. They offer good flexibility and resilience but may be less resistant to abrasive substances.

rack and pinion oil seal

3. Polyurethane This material is favored for its outstanding abrasion resistance and durability. Polyurethane seals can withstand various environmental conditions, making them ideal for heavy-duty applications.

Choosing the right material for the oil seal is critical, as it directly impacts the performance and reliability of the rack and pinion system.

Maintenance Practices

To ensure the longevity of rack and pinion oil seals, regular maintenance is essential. Users should check for signs of oil leaks and inspect seals for wear or damage. If any wear is detected, timely replacement is necessary to prevent further issues. Additionally, it's crucial to use high-quality lubricants that are compatible with the sealing materials to reduce the risk of deterioration.

Proper installation is equally vital. Misalignment during installation can lead to premature failure of the seal, resulting in leakage and contamination. Ensuring the sealing surface is clean and free from debris before installation can significantly enhance the seal's effectiveness.

Conclusion

Rack and pinion oil seals are integral to the performance of steering systems in vehicles and various machinery. By understanding their importance, the materials used, and maintenance practices, users can ensure the efficiency and longevity of their rack and pinion assemblies. Regular inspection and care can prevent costly repairs, ultimately contributing to safer and smoother vehicle handling. Whether in automotive applications or industrial machinery, attention to oil seals is key to maintaining operational integrity.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories