rack and pinion oil seal

Understanding Rack and Pinion Oil Seals Their Importance and Functionality

In the realm of automotive engineering and mechanical design, the rack and pinion mechanism is crucial for converting rotational motion into linear motion. This system is widely utilized in steering systems, where the rotational motion of the steering wheel is transformed into the lateral movement of the wheels. However, one critical component that ensures the smooth operation and longevity of this mechanism is the oil seal.

What is a Rack and Pinion Mechanism?

Before diving into the specifics of oil seals, it's essential to understand the rack and pinion mechanism itself. The rack is a flat gear that allows linear motion, while the pinion is a small gear that engages with the rack. As the pinion rotates, it moves the rack horizontally, thus directing the wheels of a vehicle. This simplicity in design is one of the reasons why the rack and pinion setup is preferred in steering systems, providing precise control and feedback to the driver.

The Role of Oil Seals

In any mechanical system, lubrication is vital for reducing friction and wear. The rack and pinion assembly is often subject to various environmental conditions, which can introduce contaminants such as dirt, dust, and moisture into the system. This is where the oil seal becomes essential. The primary function of the oil seal is to retain lubrication within the assembly while preventing external contaminants from entering.

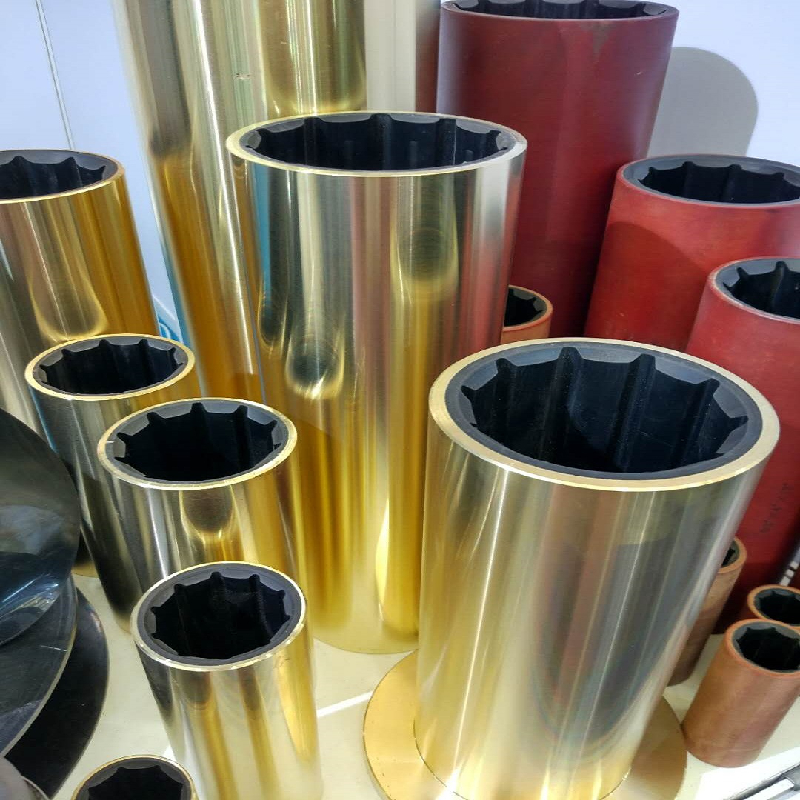

Types of Rack and Pinion Oil Seals

There are various types of oil seals used in rack and pinion systems, each designed for specific applications and environmental conditions

. Some common types include1. Rubber Oil Seals These are the most prevalent type, made from durable rubber materials that provide effective sealing against oil leaks and contaminants. They are highly resistant to wear and can operate in a wide range of temperatures.

rack and pinion oil seal

2. Mechanical Seals Often used in more demanding environments, mechanical seals offer enhanced protection against high pressure and temperature fluctuations. They are commonly used in heavy-duty applications.

3. Spring-Loaded Seals These seals incorporate a spring mechanism that helps maintain contact with the sealing surface, ensuring that the seal remains effective even as the components wear over time.

Importance of Maintenance

The longevity and efficiency of rack and pinion systems greatly depend on the proper functioning of oil seals. Regular inspection and maintenance are crucial to ensure that seals are not worn or damaged. A malfunctioning oil seal can lead to leaks that decrease lubrication, increase friction, and ultimately result in system failure.

Signs that an oil seal may need replacement include visible leaks, unusual noise from the steering mechanism, or a loose steering feel. It’s crucial for vehicle owners to be vigilant about these signs and seek professional advice when necessary.

Conclusion

In summary, rack and pinion oil seals play a fundamental role in the performance and reliability of steering mechanisms in vehicles and various industrial applications. Their ability to prevent leaks and contamination helps maintain proper lubrication, ensuring that the system operates smoothly and efficiently. As technology continues to advance, the materials and designs of these seals will likely evolve, but their fundamental role in mechanical systems will remain indispensable.

Understanding the function and importance of rack and pinion oil seals not only helps in appreciating the nuance of engineering designs but also emphasizes the need for regular maintenance and checks. For vehicle owners, being informed about such components can lead to more proactive measures, ensuring a safe and reliable driving experience. As we advance into a new era of automotive innovation, the lessons learned from the traditional rack and pinion mechanism will continue to influence modern engineering practices.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories