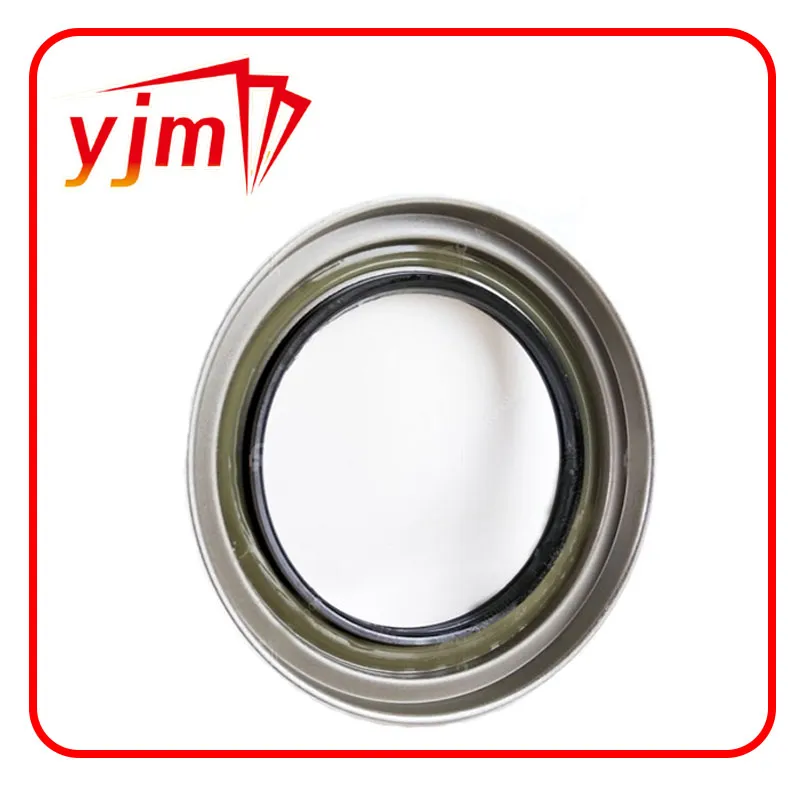

pump shaft seal

Understanding Pump Shaft Seals Essential Components in Fluid Management

In industrial applications, fluid transport is a critical function that relies on various equipment, including pumps. A vital component of these pumps is the pump shaft seal. The pump shaft seal is crucial for preventing leaks of the fluid being pumped, thereby ensuring operational efficiency and safety.

What is a Pump Shaft Seal?

A pump shaft seal is a device that seals the area where the pump shaft exits the pump casing. Its primary function is to prevent fluid leakage, which can lead to contamination, decreased efficiency, and potential safety hazards. The complexity of the seal's design is influenced by several factors, including the type of fluid being pumped, the operating pressure and temperature, and the speed of the pump shaft.

Types of Pump Shaft Seals

There are several types of pump shaft seals, with the most common being

1. Mechanical Seals These consist of two primary components—the rotating part attached to the shaft and the stationary part fixed to the pump casing. Mechanical seals are widely used in various applications because they provide a reliable sealing solution that minimizes leakage.

2. Packing Seals Often referred to as packing glands, these consist of fibrous packing materials that are compressed around the shaft. While packing seals are less efficient than mechanical seals, they are easier to maintain and are often used in lower-speed applications.

3. Lip Seals These seals are made from elastomeric materials and feature a flexible lip that contacts the shaft. Lip seals are commonly used in applications where the operating conditions allow for their effectiveness, particularly with non-corrosive fluids.

Importance of Pump Shaft Seals

pump shaft seal

The importance of pump shaft seals cannot be overstated. Firstly, preventing leaks is vital for operational efficiency. Leakage not only results in product loss but also leads to increased operational costs. Secondly, in industries where toxic or hazardous fluids are involved, inadequate sealing can pose significant safety risks. For example, leaks in chemical processing plants may lead to dangerous spills, posing threats to both personnel and the environment.

Moreover, the proper functioning of pump shaft seals extends the lifespan of the pump. When a seal fails, it can lead to components becoming inundated with the fluid being pumped, potentially causing severe damage. A well-maintained seal reduces maintenance needs and enhances the reliability of the pump system.

Factors Influencing Seal Performance

Several factors affect the performance of pump shaft seals, including

- Temperature High operating temperatures can degrade seal materials, shortening their lifespan. - Pressure High pressure can lead to increased stress on the seals, which may result in failure if not designed correctly. - Fluid Characteristics The chemical properties of the fluid being pumped (such as corrosiveness, viscosity, and temperature) will influence the choice of seal materials.

Maintaining Pump Shaft Seals

Regular maintenance is essential to ensure the longevity and effectiveness of pump shaft seals. This includes periodic inspections to identify wear and tear, as well as promptly replacing seals that show signs of degradation. Operators should also ensure that alignment of the pump shaft is correct, as misalignment can lead to premature seal failure.

Conclusion

In summary, pump shaft seals play an indispensable role in fluid management within various industries. The right choice, installation, and maintenance of these seals contribute significantly to the efficiency, safety, and durability of pumping systems. By understanding their importance and function, businesses can effectively minimize downtime and operational costs, ensuring a smoother and safer production process. Proper care of pump shaft seals not only protects the environment but also enhances overall productivity, making them a critical focus in industrial fluid transport systems.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories