Plastic Oil Drain - Eco-Friendly Solutions for Your Automotive Needs

The Surge of Plastic Oil Drains A Sustainable Solution for the Modern Mechanic

In the automotive and industrial sectors, oil maintenance plays a crucial role in productivity and safety. Oil changes, while routine, remain an essential practice that ensures machinery runs smoothly and efficiently. The introduction of plastic oil drains has transformed this process, providing an innovative solution that aligns with sustainability goals and ease of use.

Plastic oil drains offer distinct advantages over traditional metal alternatives. First and foremost, they are significantly lighter, making them easy to handle and maneuver during oil changes. Mechanic shops often go through numerous oil changes daily, and the reduced weight of plastic drains enhances worker efficiency, allowing them to carry out tasks with less physical strain. This ergonomic benefit is particularly vital in environments where speed and precision are key.

From a cost perspective, plastic oil drains are generally cheaper to produce and purchase compared to their metal counterparts. This affordability makes them accessible for small businesses and individual mechanics who are looking to reduce overhead costs without compromising on quality. Furthermore, the durability and resistance to corrosion that modern plastics offer mean that, despite the lower price, these drains can withstand extensive use, ultimately offering good value for money.

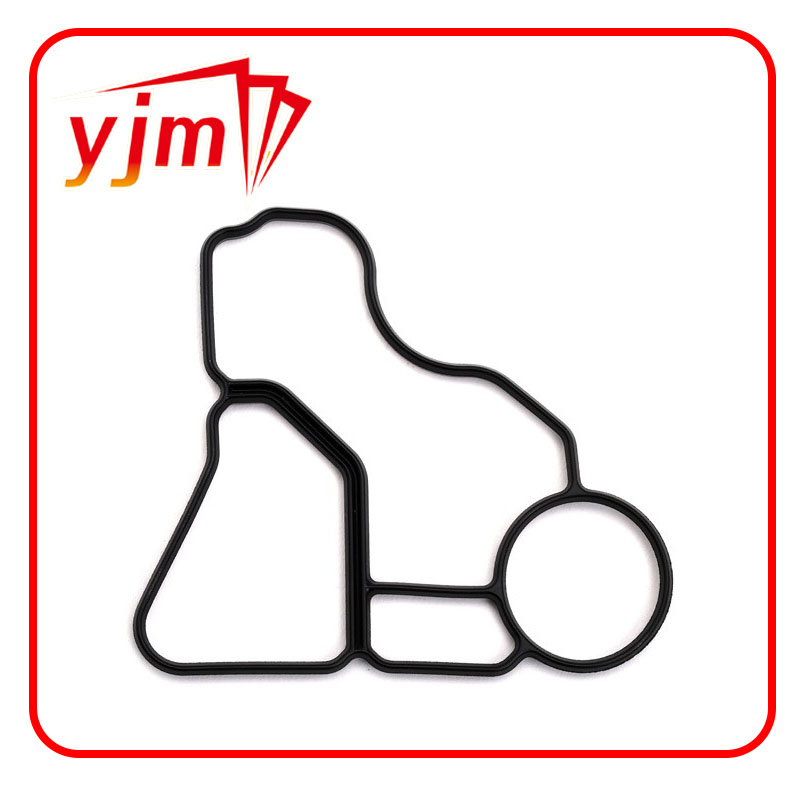

plastic oil drain

Sustainability is a critical concern in today’s world, and plastic oil drains are increasingly being manufactured from recycled materials. This not only reduces the environmental impact associated with producing new plastic but also addresses the growing problem of plastic waste. By choosing products that utilize recycled materials, garages and workshops can contribute to a circular economy, encouraging more responsible consumption and production practices within the automotive industry.

Moreover, plastic oil drains often come with features designed to optimize the oil change process. Many are designed with built-in filtration systems that help in the effective separation of oil from contaminants. This enhances the ease of disposal and ensures that used oil is managed according to environmental regulations, thereby minimizing ecological risks associated with improper disposal. Additionally, some models feature a transparent design, allowing mechanics to easily monitor the drainage process and confirm that all oil has been collected before disposal.

The rise of plastic oil drains is also reflective of a broader trend towards innovation in the automotive maintenance industry. As technology advances, new materials and designs are continuously being developed to improve efficiency and environmental impact. This commitment to innovation is essential for addressing the challenges of climate change and resource conservation.

In conclusion, plastic oil drains represent a significant advancement in the field of automotive maintenance. Their lightweight nature, affordability, and sustainable production methods make them an attractive option for mechanics and workshops around the globe. As the industry continues to evolve, the integration of environmentally friendly practices, such as the adoption of plastic oil drains, will play a pivotal role in shaping a more sustainable future for automotive maintenance. Embracing these modern solutions not only enhances operational efficiency but also contributes to a larger movement towards responsible environmental stewardship in our everyday practices.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories