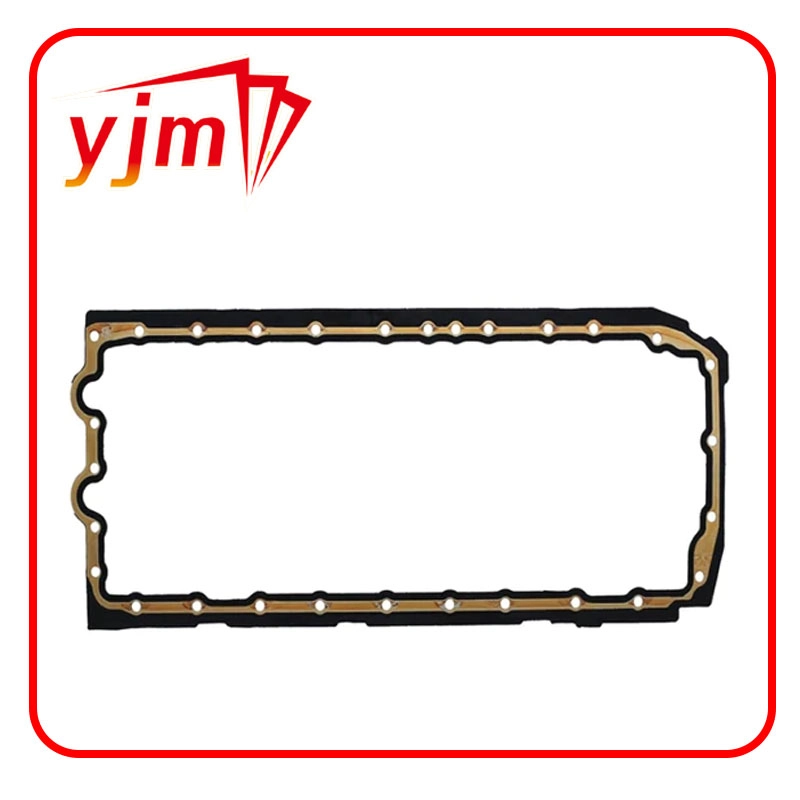

pan seal

Trustworthiness is cemented by rigorous testing and transparent communication. High pressure seals undergo extensive simulations and real-life testing to validate performance metrics. In-depth reporting ensures end-users understand the seal’s capabilities, limitations, and maintenance requirements. This transparency fosters trust and fortifies relationships between manufacturers and their clients. Moreover, expert manufacturers advocate continuous innovation. The advent of digital technologies facilitates advancements such as predictive maintenance and real-time monitoring. By integrating sensors and IoT capabilities into high pressure sealing systems, potential failures can be anticipated, enhancing reliability and safety. High-pressure seal providers also invest heavily in research and development, staying at the forefront of technological advancements. This commitment to innovation results in products that not only address current industry challenges but also anticipate future needs, maintaining relevance and adaptability in an ever-evolving marketplace. In conclusion, high pressure seals are indispensable assets in numerous industries, with their extraordinary capability to operate under extreme conditions. The confluence of experience, expertise, authority, and trustworthiness is paramount in developing seals that customers can sincerely rely on. For businesses seeking robust, reliable sealing solutions, choosing a manufacturer that embodies these qualities ensures not only superior product performance but also contributes to long-term operational success and safety.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories