Understanding Packing Shaft Seals for Enhanced Equipment Performance and Maintenance

Understanding Packing Shaft Seals Importance and Applications

Packing shaft seals play a crucial role in various industrial applications by preventing the leakage of fluids and maintaining the integrity of machinery. These seals are essential components in rotating equipment, ensuring smooth operation while safeguarding against contamination and environmental factors. This article explores the significance, types, applications, and installation techniques of packing shaft seals.

What is a Packing Shaft Seal?

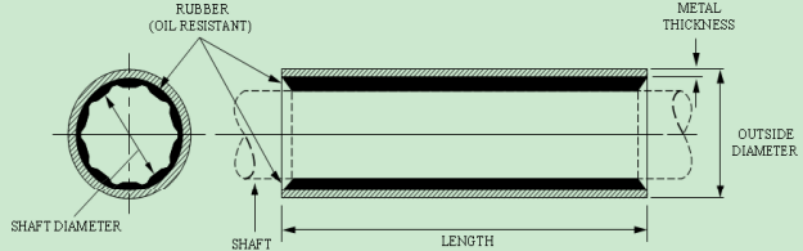

A packing shaft seal, commonly referred to as a mechanical seal or packing seal, is designed to provide a barrier between the rotating shaft and the static housing of machinery. It helps to prevent the escape of lubricants, coolants, and process fluids while also protecting the internal components from external contaminants like dust and moisture. These seals are typically made from materials such as rubber, PTFE, or other synthetic compounds, each selected for its compatibility with the specific fluids being sealed.

Importance of Packing Shaft Seals

The primary functions of packing shaft seals include

1. Leak Prevention Seals ensure that essential fluids remain contained within the machinery, preventing losses that could lead to increased operational costs and environmental hazards.

2. Contamination Protection By keeping contaminants at bay, packing shaft seals help in prolonging the life of the machinery and ensuring optimal performance.

3. Lubrication Maintenance In many applications, seals help retain lubricating oils that are crucial for reducing friction and wear between moving parts.

4. Operational Efficiency Effective sealing allows machines to operate more efficiently, reducing downtime caused by leaks or contamination-related failures.

Types of Packing Shaft Seals

There are several types of packing shaft seals, each suited for specific applications

1. Lip Seals These seals use a flexible lip to maintain contact with the shaft, providing an effective barrier against fluids. They are commonly used in automotive applications.

2. U-Cup Seals U-Cup seals are designed to provide effective sealing for reciprocating applications. Their design allows them to accommodate both pressure and low-friction movement.

3. V-Packing Seals Made up of multiple V-shaped rings, these seals are particularly useful in high-pressure applications, such as hydraulic cylinders.

packing shaft seal

4. Mechanical Seals Often used in pumps and mixers, mechanical seals consist of two faces that rotate against each other, eliminating leakage through contact.

Applications of Packing Shaft Seals

Packing shaft seals are widely utilized across various industries, including

- Oil and Gas In pumps and compressors, packing seals prevent the escape of hydrocarbons and other hazardous materials, ensuring safety and compliance with environmental regulations.

- Chemical Processing These seals are essential in reactors and mixers, where they protect against aggressive chemicals and maintain system integrity.

- Food and Beverage In this industry, packing shaft seals ensure hygiene by preventing contamination while retaining critical fluids.

- Automotive Packing seals are integral in engines and transmissions, sealing lubricating oils and preventing leaks.

Installation and Maintenance

Proper installation and maintenance of packing shaft seals are vital for ensuring their effectiveness and longevity. The installation process typically involves

1. Preparation Ensuring the shaft and housing surfaces are clean and free from damage.

2. Alignment Accurately aligning the seal to prevent uneven wear during operation.

3. Compression Adjusting the seal to the required tightness to prevent leaks without overstressing the material.

Maintenance should include regular inspections for wear, lubrication, and prompt replacement to prevent failures.

Conclusion

Packing shaft seals play an indispensable role in maintaining the efficiency and reliability of machinery across various industries. Understanding their types, applications, and proper maintenance can significantly enhance operational performance and reduce costs associated with leaks and downtime. As technology evolves, the development of more advanced seal materials and designs will continue to improve sealing efficiency, making packing shaft seals an ongoing area of innovation within industrial applications.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories