packing shaft seal

The Importance of Packing Shaft Seals in Industrial Applications

In the realm of industrial machinery, the efficiency and reliability of operations depend heavily on the integrity of components that manage fluid containment, particularly in rotating equipment. One such crucial component is the packing shaft seal. While seemingly a simple mechanical device, packing shaft seals play a pivotal role in the performance and longevity of various machines, including pumps, mixers, and turbines.

What is a Packing Shaft Seal?

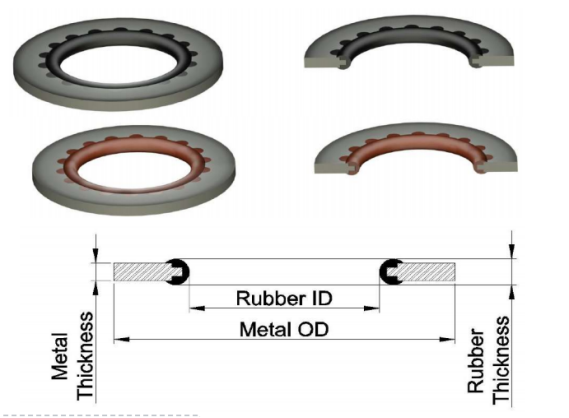

A packing shaft seal, often referred to simply as a shaft seal or packing seal, is designed to prevent the leakage of fluids from the rotating shaft of machinery. It consists of a series of braided packing materials (commonly made from graphite, PTFE, or GFO) that are compressed around the shaft. As the shaft rotates, the packing material maintains contact with it, creating a barrier that inhibits the escape of fluids and the ingress of contaminants.

Importance of Packing Shaft Seals

1. Leak Prevention The primary role of packing shaft seals is to prevent leaks. Fluid loss not only leads to operational inefficiencies but can also cause environmental concerns. In industries dealing with hazardous materials, effective sealing is vital for safety and compliance with environmental regulations.

2. Protecting Machinery By preventing fluid leakage, packing shaft seals also protect the machinery from external contaminants such as dust and moisture. These contaminants can lead to corrosion, increased wear and tear, and ultimately, equipment failure. A well-installed packing seal can extend the life of a machine significantly.

3. Cost-Effectiveness Although there might be a perception that packing shaft seals are a minor component, they can have a substantial impact on operational costs. Reducing fluid leaks minimizes waste, and maintaining machinery in optimal condition can lower repair and maintenance expenses. Additionally, a reliable packing seal can decrease downtime, allowing for smoother operations and increased productivity.

4. Versatility Packing shaft seals are versatile and can be used in a multitude of applications across different industries. From water treatment facilities to chemical processing plants, the adaptability of packing seals makes them suitable for various working conditions and fluid types.

packing shaft seal

Choosing the Right Packing Shaft Seal

Selecting the appropriate packing shaft seal is crucial for ensuring optimal performance. Several factors should be considered

- Material Compatibility The packing material must be compatible with the fluid being contained. For example, aggressive chemicals may require seals made from specialized materials that can withstand corrosion.

- Temperature and Pressure Ratings Knowing the operating temperature and pressure is essential. Different materials have varying strengths and weaknesses, and ensuring that the selected packing can handle the specific conditions is critical.

- Shaft Size and Speed The dimensions of the shaft and its rotational speed also influence the choice of packing. Seals must be sized correctly to provide an effective seal without causing excessive friction or wear.

Maintenance of Packing Shaft Seals

Proper maintenance is essential to prolong the life of packing shaft seals. Regular inspection for wear and replacement when necessary can prevent leaks from developing. Operators should monitor the performance of seals closely, as any diminishment in sealing ability can lead to increased fluid loss and require immediate attention.

Conclusion

Packing shaft seals may not be the most glamorous component in industrial machinery, but their importance cannot be overstated. They serve as the first line of defense against leaks that can incur significant costs and pose safety risks. By preventing fluid loss and protecting machinery from contaminants, they contribute to the overall efficiency, reliability, and longevity of industrial operations. When it comes to selecting and maintaining packing shaft seals, careful consideration of material compatibility, operational conditions, and routine inspections can ensure that these critical components perform at their best, keeping operations running smoothly for years to come. As industries continue to evolve, the role of packing shaft seals will remain vital in safeguarding the assets within the manufacturing and processing sectors.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories