Understanding the Importance of Proper Packing for Shaft Seals in Machinery Applications

Understanding Packing Shaft Seals Functionality and Importance

Packing shaft seals are integral components in various machinery and equipment, serving a crucial role in preventing leakage of fluids or gases from rotating shafts. They are particularly prevalent in applications involving pumps, compressors, and other rotary equipment. This article explores the functionality, types, and importance of packing shaft seals in maintaining operational efficiency and preventing environmental concerns.

What is a Packing Shaft Seal?

A packing shaft seal is designed to be fitted around a rotating shaft to create a barrier against the escape of fluids while allowing for the free movement of the shaft. These seals are typically made from elastomers or other flexible materials that can accommodate the movement of the shaft. The primary function of a packing shaft seal is to ensure that the fluid within a system remains contained while minimizing contamination from external elements.

Types of Packing Shaft Seals

There are several types of packing shaft seals, each suited for different applications and conditions. The most common types include

1. Lip Seals These are designed with a flexible lip that presses against the shaft, creating a seal that prevents the fluid from leaking. Lip seals are widely used in various machinery due to their simplicity and effectiveness.

2. Mechanical Seals Unlike traditional packing seals, mechanical seals consist of two flat surfaces that slide against each other, forming a seal without generating excessive heat. They are commonly used in pumps and high-speed applications where minimal leakage is crucial.

3. Packing Gland Seals These seals are made from soft, fibrous materials that can be compressed to fit snugly around the shaft. Packing gland seals are often used in applications with high-pressure fluids and high temperatures.

4. O-Rings These circular seals can also be utilized in shaft sealing applications. O-rings are easy to install and provide a reliable seal against low-pressure leaks.

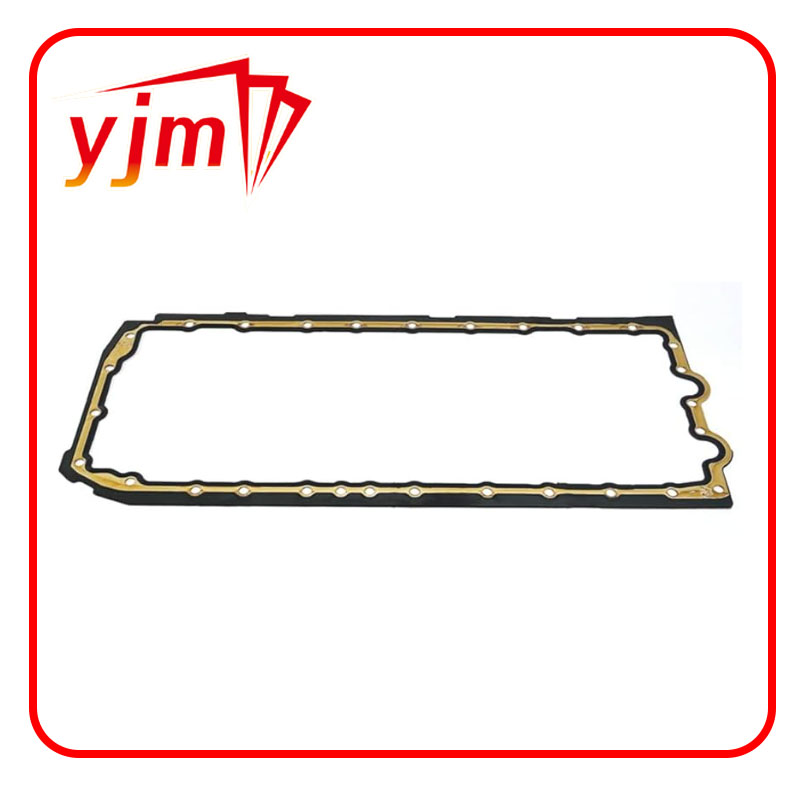

packing shaft seal

5. PTFE Seals Polytetrafluoroethylene (PTFE) seals offer high chemical resistance and can withstand extreme temperatures. They are frequently used in applications involving corrosive substances.

Importance of Packing Shaft Seals

1. Leak Prevention The primary purpose of packing shaft seals is to prevent fluid leakage, which can lead to operational inefficiencies, increased costs, and environmental hazards. Proper sealing ensures that machinery operates smoothly without loss of valuable resources.

2. Maintenance of Performance A well-functioning packing shaft seal is essential for maintaining the performance of equipment. Leaks can lead to a drop in pressure or flow rate, compromising the effectiveness of the entire system.

3. Environmental Protection In industries where hazardous fluids are contained, packing shaft seals provide a critical line of defense against spills and leaks that could harm the environment. Ensuring the integrity of these seals protects not only the equipment but also the surrounding ecosystem.

4. Cost Efficiency Regularly maintaining and replacing packing shaft seals can significantly reduce long-term operational costs. Preventing leaks minimizes the need for expensive repairs, downtime, and the potential fines associated with environmental violations.

5. Safety Packing shaft seals also play a vital role in ensuring workplace safety. Leakage of hazardous materials can pose serious risks to personnel, making the reliability of these seals crucial for any operation.

Conclusion

In summary, packing shaft seals are essential components for the smooth and safe operation of various machinery and equipment. Understanding the different types of seals and their specific applications can aid in selecting the right component for your machinery, ensuring long-term reliability and efficiency. By investing in quality packing shaft seals and embracing proper maintenance practices, organizations can enhance their operational performance while safeguarding the environment and promoting workplace safety.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories