packing gland shaft seal

Understanding Packing Gland Shaft Seals An Essential Component for Equipment Reliability

In industrial machinery and equipment, maintaining operational efficiency and preventing leaks are two primary concerns. One vital component that plays a significant role in achieving these objectives is the packing gland shaft seal. This mechanism is essential in various applications, including pumps, compressors, and turbines, where it serves to contain fluids and gases while allowing rotational motion.

What is a Packing Gland Shaft Seal?

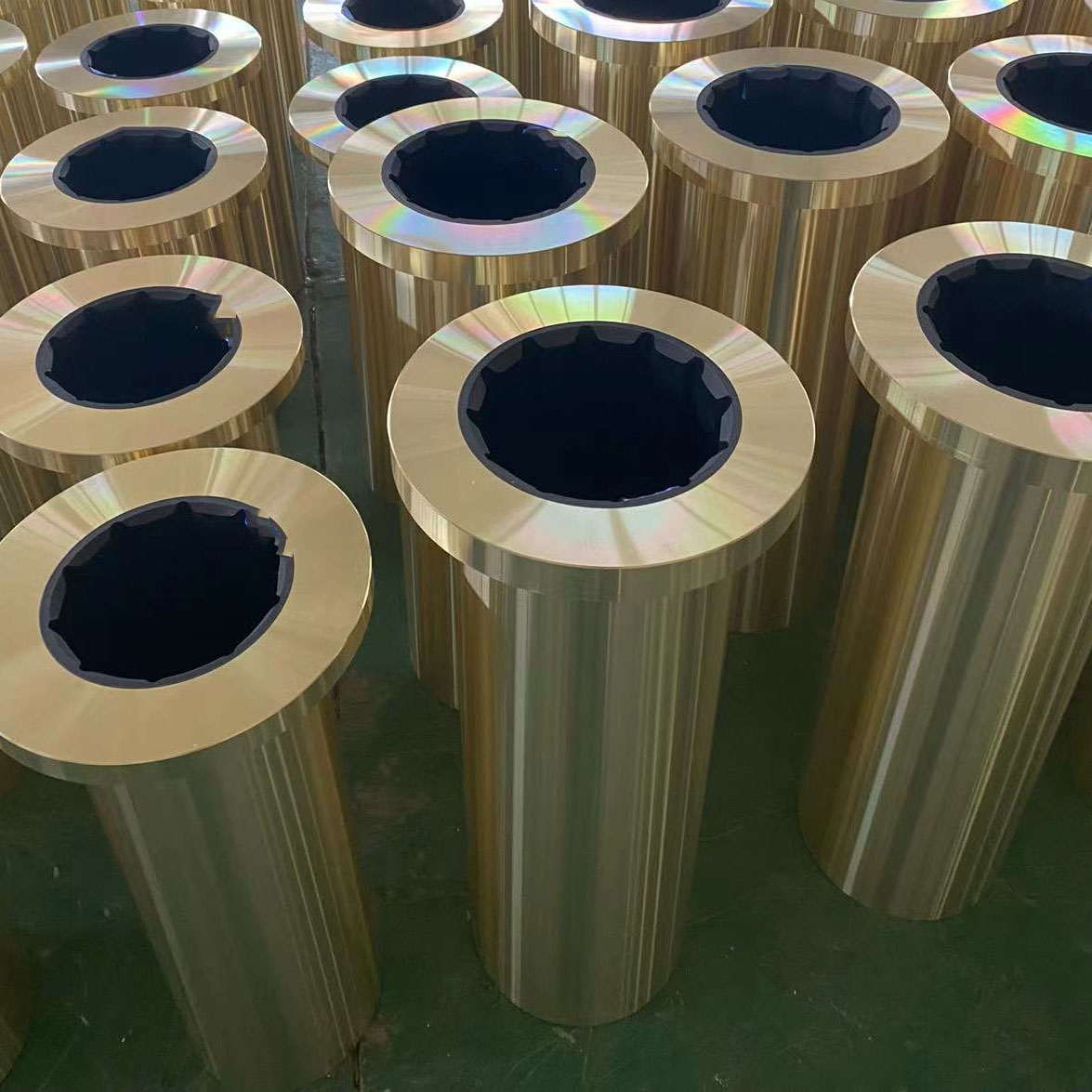

A packing gland shaft seal consists of a series of materials known as packing, which is compressed around the shaft where it penetrates a housing or casing. This packing is often made from materials like graphite, PTFE (Teflon), or rubber, which have excellent chemical resistance and can withstand varying temperatures. The packing gland itself is a housing that maintains the packing materials tightly against the shaft to prevent leaks.

How Does It Work?

The primary function of a packing gland shaft seal is to prevent the escape of liquids and gases. When the shaft rotates, the packing material compresses slightly, creating a tight seal that stops leakage while simultaneously allowing for the necessary movement. The design of the packing gland must balance the need for a secure seal with the requirement of minimal friction so that the shaft can rotate freely without excessive wear.

Advantages of Packing Gland Shaft Seals

1. Leak Prevention One of the most significant advantages of packing gland shaft seals is their ability to effectively prevent leaks of fluids or gases, which is critical in maintaining environmental safety and operational integrity.

packing gland shaft seal

2. Adjustability Packing glands are inherently adjustable. As the packing wears over time, it can be tightened to maintain the effectiveness of the seal, prolonging the service life of both the seal and the machinery.

3. Cost-Effectiveness Packing gland seals are typically less expensive than mechanical seals and are easier to maintain. This makes them a popular choice for many industries, particularly in applications with lower sealing requirements.

4. Versatility These seals can be used in various applications across multiple industries, including oil and gas, water treatment, and chemical processing, thanks to their broad compatibility with different media and operational conditions.

Challenges and Considerations

While packing gland shaft seals offer numerous benefits, they also come with challenges. Over-tightening the packing can lead to excessive friction, causing wear on the shaft and the packing material itself. Moreover, improper installation can result in leaks, negating the seal's purpose. Regular maintenance and inspection are essential to ensure that the packing gland remains effective.

Conclusion

In conclusion, packing gland shaft seals are crucial for the reliable operation of rotating machinery in many industries. Their ability to prevent leaks, combined with their adjustability and cost-effectiveness, makes them a favored choice among engineers and maintenance professionals. While they do require regular checks and maintenance to avoid issues, the advantages they bring to equipment reliability and efficiency underscore their importance in industrial applications. Understanding and properly implementing packing gland shaft seals can lead to enhanced performance and longevity of machinery, ultimately contributing to more sustainable operational practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories