Outboard Bearing Housing Assembly for Enhanced Marine Engine Performance and Durability

Understanding Outboard Bearing Carriers

Outboard bearing carriers play a crucial role in marine engineering and the performance of watercraft, especially in boats where powerful propulsion systems are necessary. These components serve as support structures that house bearings which allow for smooth rotation of the propeller shaft, ultimately facilitating optimal function and durability of the propulsion system.

What is an Outboard Bearing Carrier?

An outboard bearing carrier is typically made from robust materials such as aluminum or high-strength plastics to withstand the harsh marine environment, including saltwater exposure and high rotational forces. The carrier itself is designed to provide a stable foundation for the bearings that support the shaft extending from the engine to the propeller. By holding the bearings securely, the outboard bearing carrier ensures that the alignment of the propeller shaft is maintained during operation, minimizing wear and tear on both the shaft and the bearings.

The Functionality of Outboard Bearing Carriers

The primary function of the outboard bearing carrier revolves around load distribution. As the propeller spins, it generates thrust and lateral forces that can exert significant pressure on the propeller shaft. The outboard bearing carrier helps distribute these forces evenly, thereby preventing any one part of the shaft or bearing from experiencing undue stress. This equal distribution is critical not only for the longevity of the components involved but also for maintaining the efficiency of the vessel's propulsion.

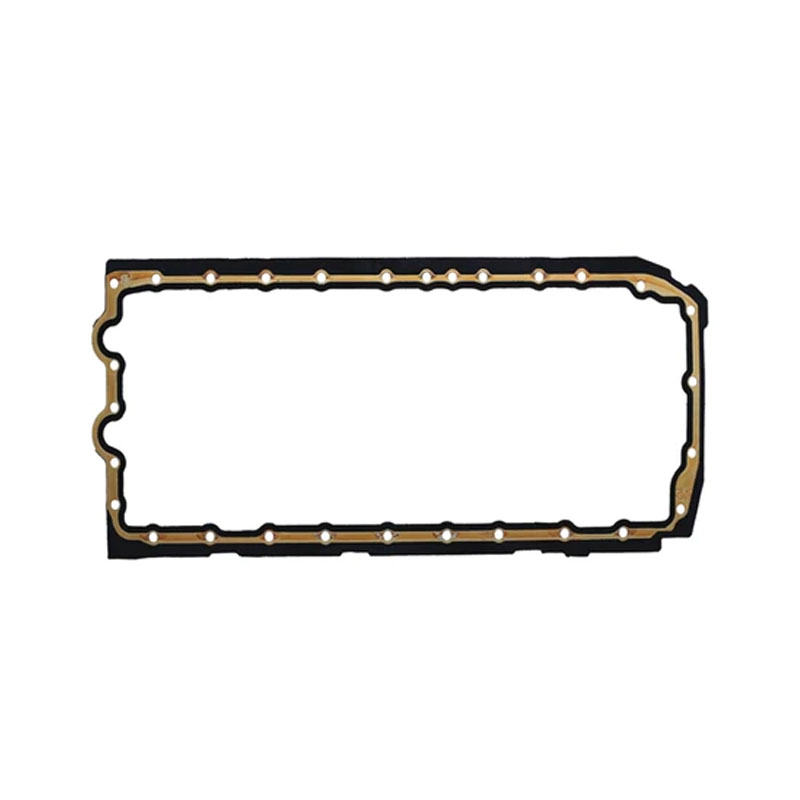

Moreover, outboard bearing carriers often feature seals or gaskets that help protect the bearings from debris and water intrusion. This adds another layer of durability, ensuring that both the bearings and the shaft remain operational in challenging conditions. The design often includes lubrication systems or grease fittings to maintain optimal lubrication, thereby reducing friction and heat generation during operation.

outboard bearing carrier

Installation and Maintenance Considerations

When dealing with outboard bearing carriers, proper installation and maintenance are paramount. Incorrect installation can lead to misalignment, resulting in accelerated wear or even catastrophic failures. It is essential to follow manufacturer guidelines and use appropriate tools to fit the carrier securely. Equally important, regular maintenance checks should be performed to ensure that any signs of wear or corrosion are identified early.

Lubrication also requires attention; insufficient lubrication can lead to increased friction, overheating, and subsequent failure. Understanding the specific lubrication requirements for the bearings involved, including the type and frequency of grease application, plays an integral role in the longevity of the outboard bearing carrier.

Conclusion

In summary, the outboard bearing carrier is a vital component of marine propulsion systems, providing essential support and stability for the bearings that help rotate the propeller shaft. Its design incorporates durability and functionality, ensuring that the stresses of operation are effectively managed. For boat owners and operators, understanding the significance of the outboard bearing carrier, along with proper installation and maintenance techniques, is crucial for optimizing the performance and lifespan of their vessels. Investing time and resources in maintaining this component can lead to significant long-term benefits, resulting in smoother, more reliable, and more efficient boating experiences.

As marine technology continues to advance, the materials and designs of outboard bearing carriers will likely evolve, offering even greater resilience and performance enhancements, thus ensuring that boaters can continue to explore the waters with confidence and peace of mind.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories