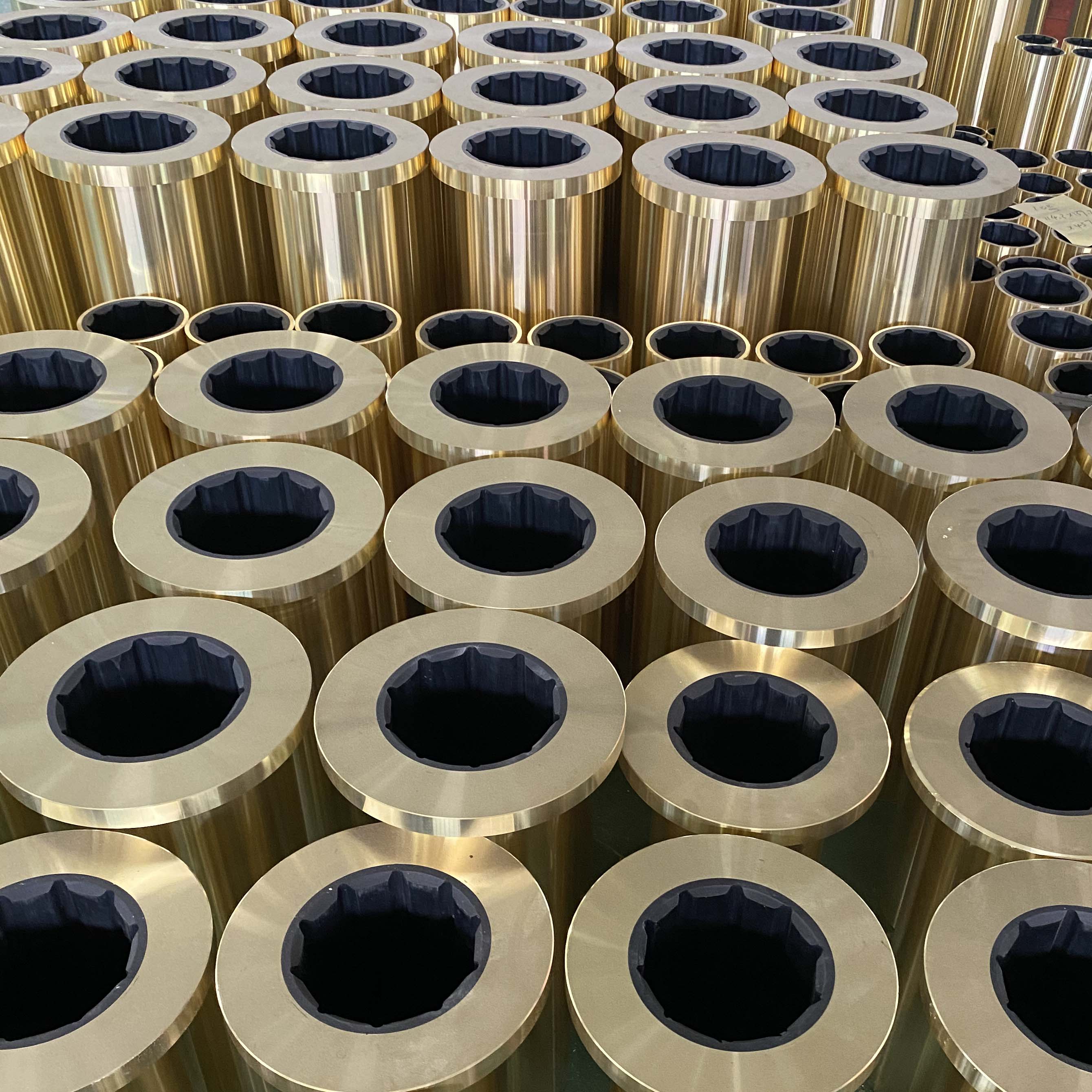

o ring shaft seal

Understanding O-Ring Shaft Seals Importance, Function, and Applications

O-ring shaft seals are crucial components in many mechanical systems, playing a vital role in preventing fluid leaks between rotating shafts and their housings. These seals are commonly employed in a wide range of industries, including automotive, aerospace, manufacturing, and robotics. Their importance cannot be overstated, as they ensure the integrity and efficiency of machinery by maintaining the necessary seal integrity, preventing contamination, and minimizing maintenance costs.

Composition and Design of O-Ring Shaft Seals

O-rings are circular seals made from various elastomeric materials, such as rubber, silicone, or thermoplastic elastomers. The design of the O-ring enables it to fit securely into a groove on the shaft or housing, creating a tight seal when compressed. The circular shape allows the O-ring to distribute pressure evenly, which enhances the effectiveness of the seal.

A notable feature of O-ring seals is their versatility in accommodating different fluid types and temperatures. Depending on the application, manufacturers can choose materials that resist chemicals, heat, and wear. For instance, if an O-ring is used in a hydraulic application, it must be resistant to hydraulic fluids. Likewise, O-rings used in high-temperature environments must be capable of withstanding significant thermal stress.

The Function of O-Ring Shaft Seals

The primary function of O-ring shaft seals is to prevent the leakage of fluids, which can include oil, water, or other lubricants, from escaping the system. This leakage can lead to several problems, including decreased efficiency, increased wear on parts, and environmental contamination. By effectively sealing the area between a rotating shaft and its housing, O-rings help maintain optimal pressure and lubrication within the system.

In addition to preventing leaks, O-ring seals also play a role in keeping contaminants out. Dust, dirt, and other particles can damage internal components if allowed to enter a mechanical system. O-rings provide a barrier that protects sensitive components, extending the life of machinery and reducing the need for maintenance and repairs.

Applications of O-Ring Shaft Seals

o ring shaft seal

O-ring shaft seals are used in a multitude of applications across various industries. In the automotive sector, they are commonly found in engines, transmissions, and differentials, where they help keep lubricants contained and prevent the ingress of contaminants. In aerospace applications, O-rings are used in hydraulic systems, fuel systems, and landing gear components, where sealing integrity is critical for safety and performance.

Manufacturing equipment also heavily relies on O-ring seals in hydraulic cylinders, pumps, and valves. Their ability to perform under high-pressure conditions makes them ideal for applications where precision and reliability are essential. Robotics and automation systems utilize O-ring seals to ensure smooth operation while preventing fluid leaks that could compromise functionality.

Choosing the Right O-Ring Seal

Selecting the right O-ring for a specific application requires consideration of various factors, including material, size, and design. The choice of material is crucial, as it must withstand the specific conditions of the application, such as temperature extremes and chemical exposure. Moreover, the size of the O-ring must match the groove dimensions to ensure proper sealing. Engineers and designers often refer to standardized sizing charts to select the appropriate O-ring.

Regular inspection and maintenance of O-ring seals are essential to prevent failures. Over time, O-rings can wear out, become brittle, or degrade due to environmental factors. Implementing a routine maintenance schedule can help identify issues before they lead to significant problems.

Conclusion

In summary, O-ring shaft seals are indispensable components in various mechanical systems. Their primary functions of preventing fluid leaks and protecting against contaminants contribute to the efficiency, safety, and longevity of machinery. With a wide array of materials and designs available, it's essential to choose the right O-ring for the specific application, taking into account the operating conditions and requirements.

As industries continue to evolve and grow, the demand for reliable sealing solutions like O-ring shaft seals will remain strong. By understanding their importance and adhering to proper maintenance practices, engineers and technicians can ensure the optimal performance of their systems, enhancing both productivity and safety.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories