Choosing the Right O-Rings for Gasoline Applications and Performance

The Importance of O-Rings for Gasoline Applications

When it comes to the safe and efficient handling of gasoline, one of the unsung heroes of mechanical design is the O-ring. This simple yet highly effective component plays a crucial role in ensuring the integrity of systems that store, transport, and utilize gasoline. In this article, we will explore what O-rings are, their materials, their significance in gasoline applications, and best practices for their maintenance and replacement.

What are O-Rings?

O-rings are circular strips made of elastomeric materials that are used as seals between two or more parts in various mechanical systems. They are designed to fit into a groove and create a seal when compressed between two surfaces. The primary function of an O-ring is to prevent the leakage of fluids or gases, which is particularly crucial in systems that handle volatile substances like gasoline.

Materials Used for O-Rings

The effectiveness of O-rings largely depends on the materials from which they are made. For gasoline applications, O-rings must possess resistance to chemical degradation, temperature extremes, and wear. Common materials include

1. Nitrile Rubber (NBR) This is one of the most widely used materials for O-rings in the gasoline industry due to its excellent resistance to petroleum oils and fuels. 2. Fluoroelastomers (FKM) These offer superior resistance to high temperatures and aggressive chemicals, making them ideal for high-performance applications.

3. Polyurethane While not as common, polyurethane O-rings provide excellent abrasion resistance and can be used in specific applications involving gasoline.

Choosing the right material for an O-ring is paramount, as it directly impacts the longevity and performance of the sealing system.

The Importance of O-Rings in Gasoline Applications

1. Leak Prevention O-rings prevent leaks in fuel systems, which is critical for both performance and safety. Even the smallest leak can lead to significant issues, including fire hazards or environmental contamination.

2. Pressure Maintenance Gasoline systems often operate under pressure. O-rings maintain this pressure by providing an effective seal, ensuring that the fuel is delivered efficiently to the engine.

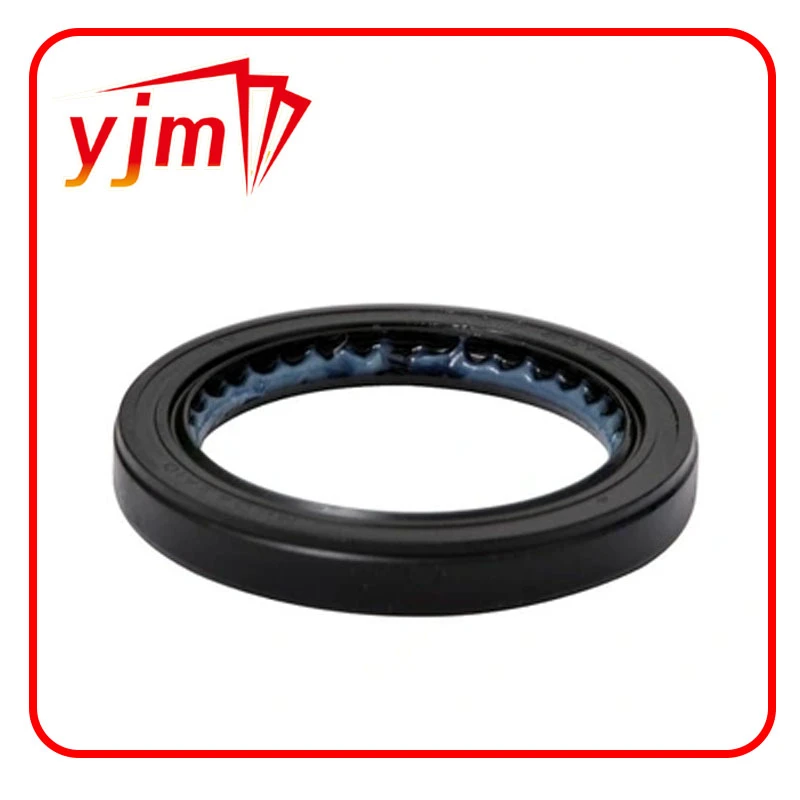

o rings for gasoline

3. Temperature Tolerance Gasoline systems can experience substantial temperature fluctuations. O-rings made from the appropriate materials can handle these changes without losing their sealing properties.

Best Practices for O-Ring Maintenance and Replacement

To ensure the longevity and reliability of O-rings in gasoline applications, it is essential to follow best practices

1. Regular Inspections Regularly check O-rings for signs of wear, such as cracking, swelling, or hardness. Early detection can prevent potential leaks and system failures.

2. Correct Installation Always ensure that O-rings are installed correctly in their grooves. Misalignment can lead to premature failure.

3. Avoid Over-Tightening Excessive tightening of the components can compress the O-ring too much, leading to deformation and loss of sealing capability.

4. Use Compatible Lubricants When installing O-rings, use lubricants that are compatible with the O-ring material and gasoline. This helps ease installation and reduces the risk of damage.

5. Replace When Necessary O-rings have a limited lifespan. When replacing components in gasoline systems, it is prudent to replace the associated O-rings to ensure optimal performance.

Conclusion

O-rings may seem like small components in the grand scheme of gasoline systems, but their role is indispensable. They ensure that gasoline remains safely contained, contribute to overall system efficiency, and maintain the integrity of mechanical operations. By understanding the materials, importance, and maintenance practices associated with O-rings, professionals can enhance the reliability and safety of gasoline applications. As technology advances, so too will the materials and designs of O-rings, continuing to protect one of the most essential resources in our everyday lives.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories