Understanding the Importance of O-Ring Sealants in Industrial Applications and Maintenance

Understanding O-Ring Sealants Their Importance and Applications

O-ring sealants are critical components in various industries, playing an essential role in preventing leaks and ensuring the integrity of mechanical systems. These circular seals are made from elastomeric materials, which allow them to flex and compress when installed in a groove between two mating surfaces. Their primary function is to create a barrier that inhibits the escape of fluids or gases under pressure, making them indispensable in applications ranging from automotive to aerospace.

Understanding O-Ring Sealants Their Importance and Applications

One of the significant advantages of O-rings is their versatility. They can be designed in various sizes and shapes to fit specific applications. The O-ring's circular cross-section allows for uniform compression when installed, which is vital for maintaining a proper seal under varying pressure conditions. This flexibility ensures that O-rings can adapt to the dynamics of the systems they are a part of, whether in hydraulic machinery or household appliances.

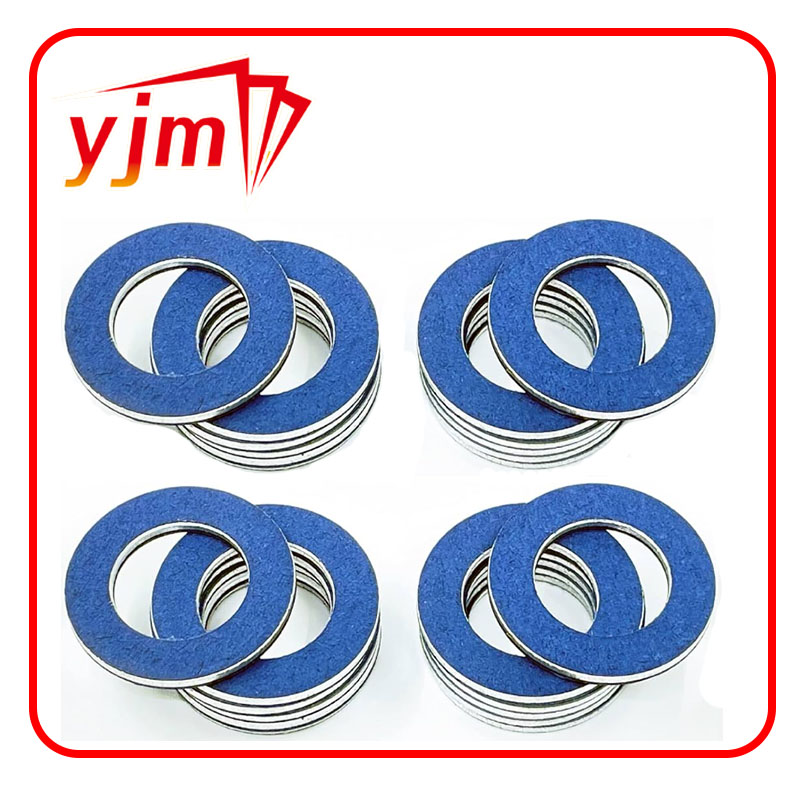

o ring sealant

Installation of O-ring sealants requires careful consideration to avoid common pitfalls that can lead to failure. For instance, the groove design must match the O-ring dimensions to ensure proper sealing. Additionally, contaminants during installation can affect the material properties and seal integrity. Thus, technicians often adhere to strict cleanliness protocols to ensure optimal performance.

The maintenance of O-ring seals is another crucial aspect to consider. Over time, exposure to harsh chemicals, extreme temperatures, or mechanical wear can lead to degradation of the seal, resulting in leaks. Regular inspection and replacement of O-rings can prevent equipment failure and subsequent costly repairs.

In industries such as aerospace, where the stakes are notably higher, the reliability of O-ring seals becomes paramount. In aircraft, for example, these seals are vital in fuel systems, cabin pressure controls, and hydraulic systems, where any leakage could compromise safety and performance. Engineers often conduct rigorous testing, including thermal cycling and pressure testing, to ensure that O-rings meet stringent safety standards.

In conclusion, O-ring sealants are essential components that promote the efficiency and reliability of various mechanical systems across multiple industries. Their design, material selection, and maintenance are critical for optimal performance. As technology continues to advance, so too will the development of more resilient and adaptable O-ring materials, ensuring their continued utility in modern applications. Understanding these seals is pivotal, not just for engineers and technicians, but for anyone involved in industries where fluid and gas containment is paramount.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories