Understanding O-ring Seals and Their Applications in Various Industries

Understanding O-Ring Seals An Essential Component in Engineering

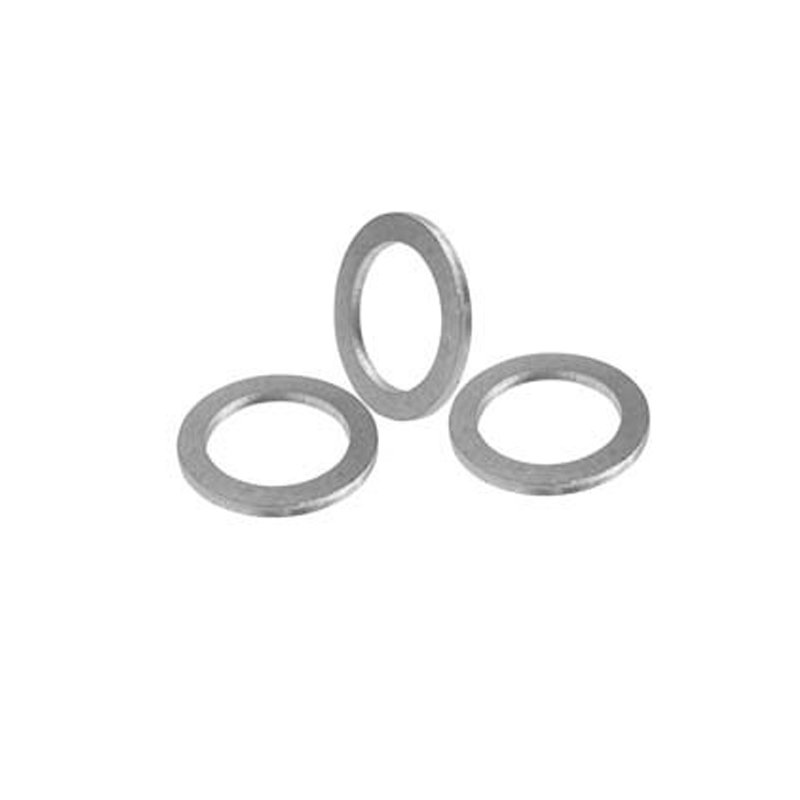

O-ring seals are critical elements in many mechanical systems, used primarily for sealing applications to prevent leaks. These simple, yet highly effective components are found in a variety of industries, from automotive to aerospace, and even in household appliances. Understanding the characteristics and applications of O-ring seals is essential for engineers and technicians alike.

What is an O-Ring Seal?

An O-ring is a circular, ring-shaped elastomer, typically made from rubber, silicone, or a variety of thermoplastics. Its design, resembling the letter “O,” allows it to be placed in a groove between two mating surfaces to create a seal. When compressed, the O-ring conforms to the surfaces and fills the gap, thus preventing the passage of fluids or gases.

Types of Materials

The material selection for O-rings is paramount, as it directly affects their performance, durability, and suitability for specific applications. Common materials include

- Nitrile (NBR) This is the most widely used O-ring material, known for its resistance to petroleum-based oils and fuels, making it ideal for automotive applications.

- Fluorocarbon (FKM) Offered for higher-temperature applications, this material is highly resistant to chemicals and offers excellent thermal stability, often used in aerospace and chemical processing.

- Silicone (VMQ) Known for its temperature resistance, silicone O-rings are ideal for extreme environments but have lower mechanical properties compared to other materials.

- Polyurethane This material provides excellent abrasion resistance, making it suitable for applications that involve high wear and tear.

Applications of O-Ring Seals

O-ring seals are utilized in an array of applications, which include

o ring seal

1. Automotive O-rings are commonly used in engines, fuel systems, and hydraulic systems, where they help contain fluids and prevent leaks.

2. Aerospace In aircraft engines and systems, O-rings must endure extreme temperatures and pressures, ensuring safety and efficiency.

3. Manufacturing Many manufacturing equipment and machinery rely on O-rings to maintain their operational integrity, preventing leaks in hydraulic systems and pneumatic controls.

4. Consumer Products Items such as faucet valves, showerheads, and even appliances may use O-rings to ensure water tightness and prevent drips.

Advantages of O-Ring Seals

The advantages of O-ring seals are numerous

- Versatility They can be used in rotary or linear applications and can seal gases or liquids across various industries.

- Cost-Effectiveness O-rings are relatively inexpensive to manufacture and replace, making them a cost-effective sealing solution.

- Easy Installation Their simple design allows for easy assembly and replacement without the need for special tools or processes.

- Reliable Performance When properly selected for the application, O-rings provide excellent sealing performance, ensuring the integrity of systems.

Conclusion

In engineering, O-rings may seem like simple components, but their role is anything but trivial. They are integral to the functionality and reliability of countless systems and devices. When designing or maintaining mechanical systems, understanding the properties and appropriate applications of O-ring seals can lead to better performance, improved safety, and longer-lasting products. As industries continue to evolve and innovate, the importance of O-ring seals will undoubtedly remain, adapting to meet the new challenges presented by modern engineering demands.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories