Understanding the Function and Benefits of O-Ring Piston Seals in Various Applications

Understanding O-Ring Piston Seals A Comprehensive Overview

O-ring piston seals are a pivotal component in hydraulic and pneumatic systems, designed to provide a reliable seal between the piston and the cylinder wall. These seals play a crucial role in maintaining pressure, which is essential for the efficient operation of various machines and equipment. This article delves into the functionality, applications, and advantages of O-ring piston seals, along with factors that influence their performance.

What Are O-Ring Piston Seals?

An O-ring is a circular ring made of elastomeric materials, which can be utilized in static and dynamic applications. When it comes to piston seals, the O-ring fits into a machined groove on a piston and forms a tight seal against the cylinder wall. The primary function of this seal is to prevent the fluid or gas from leaking past the piston, thereby ensuring that the system maintains the necessary pressure for operation.

How Do O-Ring Piston Seals Work?

When hydraulic or pneumatic pressure is applied, the O-ring compresses slightly between the piston and the cylinder wall. This compression creates a dynamic seal that withstands varying pressures. The flexible nature of the O-ring allows it to accommodate slight misalignments or surface imperfections on the piston and cylinder walls, which further enhances its sealing capability.

Dynamic sealing refers to the O-ring's ability to maintain a seal under motion. When the piston moves, the O-ring adapts to the movements of the components, ensuring that the system remains leak-proof. This adaptability is vital for systems where reciprocating or rotating motion is involved.

Applications of O-Ring Piston Seals

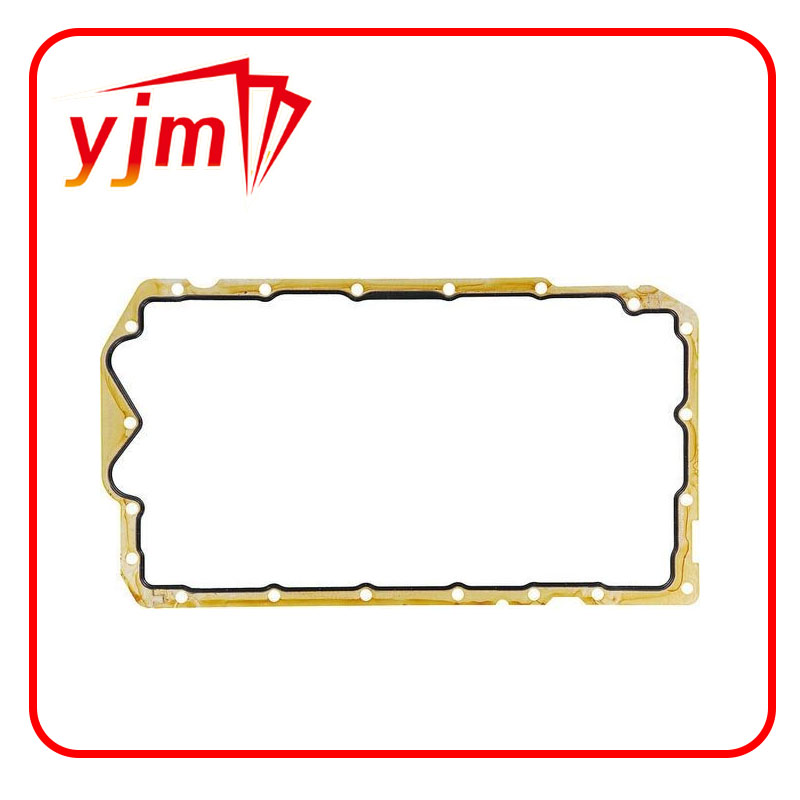

o ring piston seal

O-ring piston seals are widely used in various applications, primarily in hydraulic cylinders, pneumatic cylinders, and internal combustion engines. In hydraulic systems, they are crucial for controlling fluid power in machinery such as forklifts, excavators, and various industrial equipment. In pneumatic applications, these seals maintain pressure in systems where air or gas is compressed for operation, such as in air brakes and pneumatic tools. Similarly, in engines, O-ring seals can help contain combustion gases and maintain oil pressure.

Advantages of O-Ring Piston Seals

One of the major advantages of O-ring piston seals is their simple design, which allows for easy installation and replacement. They are also relatively inexpensive compared to other sealing options, making them economically viable for various applications. Additionally, O-rings are available in a wide range of materials, including nitrile, fluorocarbon, and silicone, which allows them to be tailored to specific applications depending on temperature, pressure, and fluid compatibility.

Another significant benefit is their reliability and longevity. When installed correctly and used within the limits of their specifications, O-ring piston seals can provide a long service life, minimizing the need for frequent maintenance and replacements. They are also effective in reducing friction between moving parts, which can enhance the efficiency of the system overall.

Factors Influencing Performance

While O-ring piston seals offer numerous benefits, their performance can be influenced by several factors. Temperature and chemical exposure can lead to degradation of the elastomer material, affecting the seal's integrity. Additionally, improper installation or incorrect sizing of the O-ring can result in leaks or premature failure. Therefore, it is essential to choose the right material and dimensions based on the specific operational conditions of the system.

In conclusion, O-ring piston seals are an essential component in modern hydraulic and pneumatic systems. Their ability to provide effective sealing, combined with their economical nature and ease of use, makes them a preferred choice in various industries. Understanding their functionality, applications, and the variables impacting their performance can help ensure optimal operation in mechanical systems.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories