o ring piston seal

Understanding O-Ring Piston Seals Components, Applications, and Best Practices

When designing fluid power systems, ensuring a secure seal is critical for maintaining performance and efficiency. One of the most commonly used sealing solutions in hydraulic and pneumatic systems is the O-ring piston seal. This circular, elastomeric component is essential for preventing leaks and maintaining pressure, significantly impacting the reliability and longevity of various machinery.

What is an O-Ring Piston Seal?

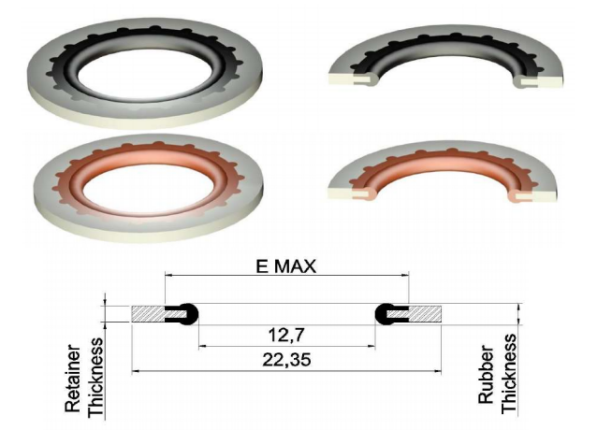

An O-ring is a toroidal-shaped ring made of elastomeric materials, such as rubber or silicone, designed to fit into a groove and create a seal between two or more parts. When used as a piston seal, O-rings serve to stop the flow of fluids or gases between different parts of a hydraulic or pneumatic cylinder. The unique cross-sectional shape enables the O-ring to deform slightly when compressed, filling the gaps between the mating surfaces, thus ensuring a hermetic seal.

Key Components of O-Ring Piston Seals

1. Material Selection The choice of material for O-rings is critical, as it directly influences the seal's performance. Common materials include Nitrile (Buna-N), Fluoroelastomer (Viton), and EPDM, each offering unique properties suited for specific applications, such as resistance to temperature, chemicals, and wear. 2. Size and Tolerance O-rings come in various sizes and cross-sections, which must be selected based on the design specifications and the environment in which they will function. Proper sizing ensures that the O-ring can sufficiently compress to form an effective seal without leading to extrusion or premature wear.

3. Groove Design The design of the groove where the O-ring sits is crucial for its effectiveness. Engineers must consider the groove dimensions, finish, and tolerances to ensure that the O-ring remains properly seated throughout its operation. This design is especially important in dynamic applications where there will be continual movement.

Applications of O-Ring Piston Seals

O-ring piston seals are widely used across various industries, including

o ring piston seal

- Hydraulics In hydraulic cylinders, O-rings provide effective sealing to ensure that pressurized fluids do not leak out, maintaining system pressure for optimal operation. - Automotive In automotive engines and transmission systems, O-ring seals are employed to prevent fluid leaks and maintain pressure in systems such as fuel injection pumps and oil distribution channels. - Aerospace O-rings are used in high-performance aerospace applications, where sealing integrity is essential for performance and safety under extreme conditions. - Manufacturing In manufacturing equipment, O-ring seals help in preventing contaminants from entering operational systems, ensuring smooth and efficient manufacturing processes.

Best Practices for O-Ring Piston Seals

To maximize the effectiveness and lifespan of O-ring piston seals, consider the following best practices

1. Installation Proper installation is critical. Care should be taken to avoid twisting or damaging the O-ring during installation, as this can lead to future failures. Utilizing installation tools specifically designed for O-rings can assist in achieving a correct fit.

2. Regular Maintenance Regular inspections can identify signs of wear or damage. Monitoring the seals for leaks, wear, or deformation can prevent catastrophic failures in systems where O-ring seals are employed.

3. Compatibility Considerations Ensure that the O-ring material is compatible with the fluids and gases it will contact. Choosing the wrong material can lead to rapid degradation, resulting in leaks and loss of system efficiency.

4. Temperature Management Understanding the operating temperature ranges is paramount. O-rings should be selected based on the expected environmental conditions to ensure optimal performance and longevity.

Conclusion

In summary, O-ring piston seals are vital components in various applications, providing critical sealing functions in hydraulic, automotive, aerospace, and manufacturing systems. By understanding their design, application, and best practices for installation and maintenance, engineers can ensure optimal performance in the systems that rely on these unassuming yet incredibly efficient components. Whether it’s preventing leaks or maintaining pressure, the role of O-ring piston seals in modern mechanics cannot be overstated. As technology advances, continuous improvements in materials and designs will further enhance their reliability and effectiveness in various applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories