O-ring Failure and Its Impact on Sealing Performance in Various Applications

The Importance of O-Ring Seals in Industrial Applications

O-rings are small, circular components that play a crucial role in various industrial applications. Often made from elastomeric materials, these seals are designed to provide a barrier against the leakage of fluids and gases. Yet, despite their simplicity, many users encounter issues related to O-ring sealing failures. This article explores the importance of proper O-ring sealing, common causes of failure, and strategies for ensuring effective sealing in various applications.

Understanding O-Ring Seals

O-rings are universally used across multiple sectors, including automotive, aerospace, and petrochemical industries. They function as seals in static and dynamic applications, preventing leaks that could lead to inefficient processes or catastrophic failures. Their design allows them to compress against the mating surfaces, creating a tight seal that can withstand varying pressures and temperatures.

Common Causes of O-Ring Seal Failure

Despite their effectiveness, O-rings can fail to seal properly due to several reasons. Understanding these can aid in troubleshooting and maintaining optimal performance.

1. Material Selection One of the most critical aspects of O-ring sealing is choosing the right material. Different materials have varying levels of resistance to temperature, pressure, and chemical exposure. For example, using a rubber O-ring in a high-temperature environment can lead to degradation and failure. Therefore, it is essential to select materials compatible with the specific operating conditions.

2. Improper Installation Incorrect installation is another frequent cause of sealing failures. O-rings must be installed without twists or kinks, as these imperfections can create pathways for leaks. Additionally, lubrication is often required to facilitate installation and mitigate friction during operation. Failing to apply the proper lubricant can lead to premature wear and failure of the O-ring.

3. Compression and Sizing Issues O-rings are designed to compress when installed; however, insufficient or excessive compression can lead to failure. The correct size should be chosen based on the dimensions of the groove and the operational pressure. If the O-ring is too large, it may not fit properly, while a small O-ring may not provide adequate sealing under pressure.

4. Degradation from Environmental Factors O-rings can be susceptible to degradation from exposure to chemicals, UV light, and ozone. Environmental stressors can compromise the integrity of the material, leading to cracks or brittleness. Regular inspections and replacements based on the operating environment are essential in preventing such failures.

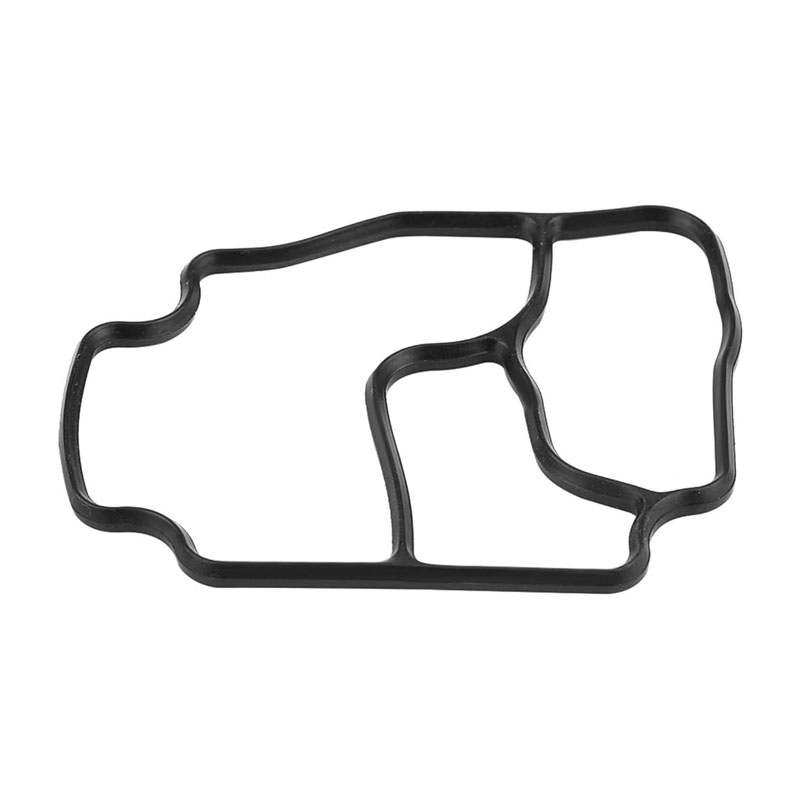

o ring not sealing

5. Dynamic Applications In applications with moving components, O-rings face additional challenges. Dynamic sealing can introduce wear and tear not typically encountered in static applications. Proper design considerations, such as the speed of movement and the presence of vibration, should be incorporated to ensure effective sealing in dynamic cases.

Strategies for Preventing O-Ring Seal Failures

To maintain the integrity of O-ring seals, various strategies can be employed

- Regular Maintenance Establishing a routine inspection and maintenance schedule can help identify potential sealing issues before they escalate. Regular checks can ensure that O-rings are in good condition and free from wear, allowing for timely replacements.

- Optimizing Design Engineers should prioritize design elements that accommodate the specific needs of the application. This includes properly sized grooves, the right material selection, and considering the operational environment during the design phase.

- Training Personnel Providing training for individuals involved in the installation and maintenance of O-rings can significantly reduce improper handling. Educated staff can better understand the importance of material selection, installation techniques, and regular assessments.

- Implementing Quality Control Quality assurance processes can help ensure that the materials used for O-rings are of high quality and suitable for their intended applications. This includes sourcing from reputable manufacturers and conducting material tests before installation.

Conclusion

O-rings are integral components in the sealing processes of many industries, yet failures can lead to significant operational hurdles. By understanding the common causes of O-ring sealing failures, and implementing preventative strategies, businesses can enhance their reliability and efficiency. Ultimately, the importance of proper O-ring sealing cannot be underestimated, as it underpins the safe and efficient operation of countless systems globally.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories