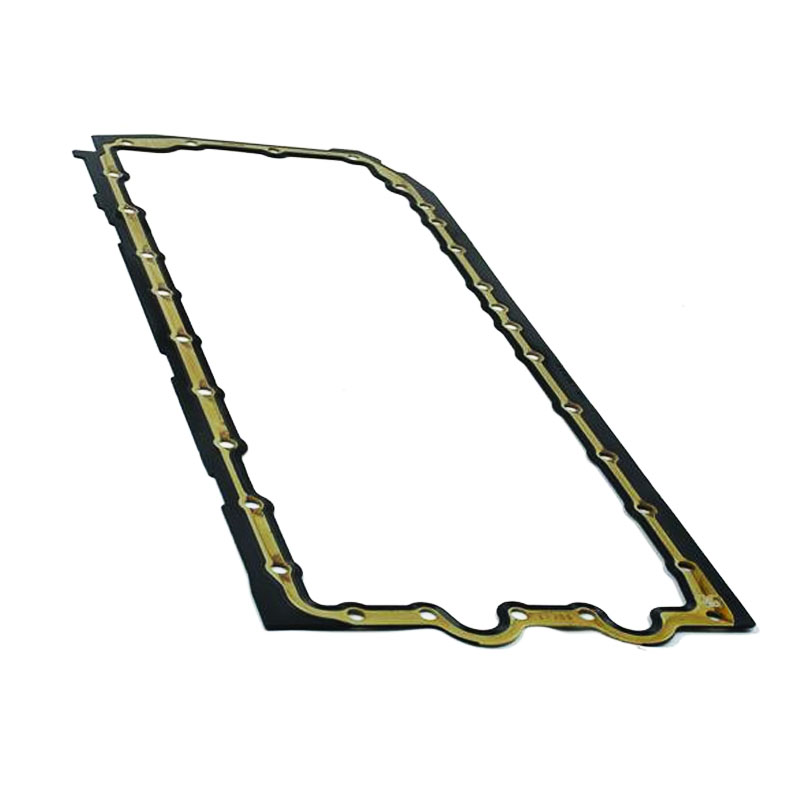

o ring flange seal

Understanding O-Ring Flange Seals A Comprehensive Guide

O-ring flange seals are essential components in a variety of industrial applications, playing a critical role in ensuring the integrity and reliability of equipment and systems. These seals are commonly used where flanged joints are present, providing a robust solution to prevent leaks of fluids or gases. In this article, we will explore the design, materials, advantages, and applications of O-ring flange seals, as well as key considerations for their effective implementation.

What is an O-Ring Flange Seal?

An O-ring flange seal consists of a circular cross-section sealing element, or O-ring, that is seated in a groove on the flange surface. When the flanges are bolted together, the compression of the O-ring creates a tight seal that prevents the escape of fluids or gases. The design of the O-ring and the specific arrangement of the flanges work together to provide a reliable sealing mechanism that can withstand various pressures and temperatures.

Materials Used in O-Ring Flange Seals

The performance of O-ring flange seals is highly dependent on the materials used. Common materials for O-rings include

1. Nitrile Rubber (NBR) Known for its excellent resistance to oil and fuel, NBR is one of the most widely used materials for O-ring seals. 2. Fluoroelastomer (FKM) With superior resistance to high temperatures and harsh chemicals, FKM is ideal for applications requiring durability and performance. 3. Silicone Offering good thermal stability and flexibility, silicone O-rings are often used in applications involving extreme temperatures. 4. Polyurethane Known for its high tensile strength and abrasion resistance, polyurethane O-rings are suitable for demanding environments.

The choice of material will depend on the specific requirements of the application, including resistance to chemicals, temperature range, and mechanical stresses.

Advantages of O-Ring Flange Seals

O-ring flange seals provide numerous advantages, making them a popular choice in various industries

o ring flange seal

1. Versatility O-ring seals can be used in a wide range of applications, from automotive to aerospace, and from hydraulic systems to oil and gas pipelines. 2. Cost-Effective Compared to other sealing methods, O-ring seals are relatively inexpensive and easy to replace, resulting in lower maintenance costs. 3. Ease of Installation The installation of O-ring flange seals is straightforward, which can reduce downtime during maintenance or assembly. 4. Effective Sealing O-ring seals can effectively handle different pressures and thermal conditions, making them reliable in various environments.

Applications of O-Ring Flange Seals

O-ring flange seals are utilized across a broad spectrum of industries, including

- Hydraulics Ensuring leak-free connections in hydraulic systems which are crucial for equipment performance. - Automotive Used in engine components and fluid systems, O-rings help maintain efficiency and prevent leaks. - Aerospace In aircraft systems, O-ring seals help to maintain integrity and safety by preventing fluid leaks under extreme conditions. - Oil and Gas Vital for pipeline connections and drilling equipment, O-rings ensure the secure transport of oil and other gases without leaks.

Considerations for Implementation

When implementing O-ring flange seals, several factors must be considered to ensure optimal performance

1. Sizing Proper sizing is critical; an improperly sized O-ring can lead to leaks or equipment failure. 2. Surface Finish The surface finish of the flange surfaces can affect the seal's performance. A smoother finish is usually preferable. 3. Assembly Care should be taken during assembly to avoid damaging the O-ring, which can compromise its sealing ability. 4. Temperature and Pressure Ratings Ensure that the selected O-ring material is appropriate for the expected temperature and pressure conditions of the application.

Conclusion

O-ring flange seals are vital components in a multitude of industrial settings, offering reliability, cost-effectiveness, and versatility. By understanding their design, materials, and applications, as well as considering critical implementation factors, engineers and technicians can ensure the optimal performance of sealing systems across various environments. Properly utilized, O-ring flange seals significantly contribute to the efficiency and safety of mechanical and fluid systems.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories